Lecture

Internal organization variables — labor resources, equipment, inventories, and technology — can be seen in terms of a model for the production of goods and services.

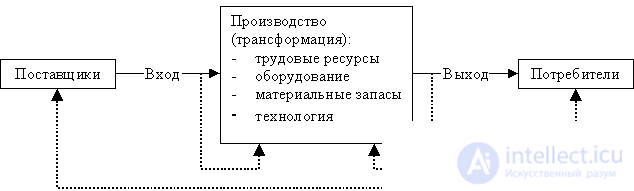

Imagine a model of the process of production of goods and services in the form of a scheme: input - transformation - output.

Fig. 2.4. Model of the process of production of goods and services

Commenting on this model, it should be noted that the purpose of the organization of production is to ensure communication between suppliers of goods or services and consumers. The solid lines in the diagram show the movement of goods and services. Dotted lines reflect the movement of information. This information allows you to determine how well the work is organized in the enterprise. The most important part of the model is the transformation itself - the transformation of the original product into the final one.

The main components of the production process in the model under discussion are labor resources, equipment, inventories and technology.

Labor resources. Speaking about the professionalism of the manager * , it is necessary to keep in mind two aspects. First, he must know what and how to do in order to most effectively produce goods or services. Appropriate workplace equipment, methods of work performance, equipment providing analysis of the results are all necessary to ensure that the production process * proceeds efficiently and at the proper level.

The second thing a manager needs to know is how many employees, what professions should he involve. After the manager adjusts the scope of work and the number of employees, he will be able to determine the quality and quantity of products. When calculating the need to take into account the conformity of products to standards, production rate and quality level. To achieve the required level of quality, various schemes of material incentives, bonuses, the creation of favorable working conditions, etc. can be applied. The reliability of personnel is an important element in ensuring productivity. High staff turnover and absenteeism speak of low personnel reliability and, as a result, low productivity.

People are central to any management model. Managing people who are distinguished by high entrepreneurial abilities is high art, and the basis of all profits and losses depends entirely on what the payment and incentive system is.

Equipment. There are three important qualities of equipment - power, versatility and reliability. The rated power is that for which the device was designed during its design. The real power is the one with which the device actually works.

Equipment efficiency is the ratio of real power to nominal. The versatility of the equipment shows how easy it is to change equipment to perform any other work. Thus, general-purpose equipment has a high readability, and special-purpose equipment - low. Reliability shows how long the equipment can work in its original form. The increase in downtime and the cost of maintenance will indicate that the equipment has low reliability. The development of mechanization, standardization of equipment, assembly lines, computerization of equipment has a great impact on the nature of responsibilities and tasks, the qualifications and content of the work, including management in general.

Inventories are acquired or accumulated in order to ensure the production of goods and services. In our case, we will focus only on what is being bought (in the above scheme, it passes through the input and then is converted). There are three main types of inventories. Stocks of raw materials are stocks of materials that accumulate before the production process. Inventories of unfinished products accumulate during the production process, in fact, they are unfinished products that are in production. Finished goods stocks are finished goods that are not yet sold to the consumer.

One of the reasons why material inventories are necessary is to ensure the continuity of the production process. The second reason is to ensure the independence of the production process from market conditions; this is what they mean when they talk about reserve stock . How much and what inventories should an organization have? It is quite difficult to answer this question. The merchant will want to have as much finished product as possible in order to sell it as soon as possible. The financier prefers not to have any stocks, at least some raw materials, in order to reduce the immobilization of money. The manufacturer ideally needs an equal amount of all types of stocks in order not to suffer from the sluggishness of suppliers, to make the individual stages of the production process independent of each other and to be able to fulfill urgent orders of consumers. In addition, you must consider the cost of storage. Therefore, there are several approaches to inventory management. Distinguish between control systems with a fixed quantity, a system with a fixed time or a system "just in time". Each of them has its advantages and disadvantages.

Technology as an internal variable has a broad meaning and is defined as a means of converting raw materials — whether people, information, or physical materials — into the products and services sought, in essence, it represents a way that allows such a transformation to take place. Technological processes are very diverse.

Technological innovations affect the efficiency of manufacturing products, the rate of obsolescence, the efficiency of information processing, as well as what kind of services and new products consumers expect from the organization. There are, for example, cases when a small company produced a new integrated circuit, which led to the need to remove the entire product from the production of a large company. It follows that the organization must be able to quickly respond to new developments and offer innovations themselves. This need for rapid response to technological innovations can be confirmed by a brief list of the latest innovations that have deeply affected organizations and society — computer, laser, microwave, semiconductor technologies, robotics, and genetic engineering.

Comments

To leave a comment

Management

Terms: Management