Lecture

In the organization of the production process * , the timing of all its parts is important. The purpose of this coordination is the smooth operation of equipment and workers.

The production cycle (production time) is the calendar period of time from the moment the objects of labor are launched into the production process until the finished product leaves it.

In practice, use the concept of the duration of the production cycle (T C) the manufacture of a product or its parts: assemblies, parts, blanks.

The duration of the production cycle is most often expressed in days, and with low labor intensity of products - in hours.

The duration of the production cycle is influenced by the structure of the production process and the nature of operations. Therefore, its reduction is associated with the improvement of product design, technological processes, organization of labor and production. A reduction in the production cycle affects the increase in production efficiency — an increase in the rate of output, an improvement in the use of fixed assets and working capital, and an increase in capital productivity.

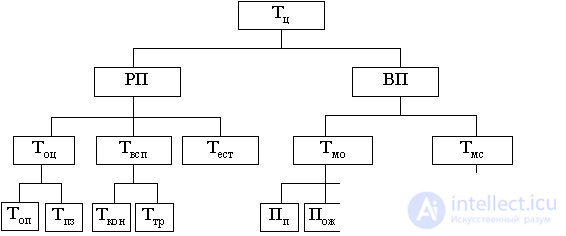

The structure of the production cycle is shown in Fig. 8.1.

Fig. 8.1. The structure of the production cycle.

The following symbols are used in the figure:

RP - working period;

VP - time of breaks;

T ots - the operating cycle (operating time);

T op - time of technological operations (operational time);

T пз - the time of preparatory and final * works;

T VSP - time auxiliary operations;

T con - time control operations;

T Tr - the time of transport operations;

T eats - the time of natural processes (natural drying of colored products, natural aging of castings, etc.);

T mo - time interoperational breaks;

T ms - time interchangeable breaks;

P n - breaks of batch, caused by the passage of objects of the party before the start of processing on the operation and after it until the end of processing the entire batch. A batch is the number of identical objects of labor that are simultaneously launched into production with a one-time expenditure of preparatory and final time * . Each object of labor in the party, except the first and last, lies down twice - before the start of processing and at the end of it;

FEs are waiting interruptions caused by the staying of a batch of objects in the workplace due to its employment in the manufacture of other items;

P com - picking breaks caused by the passage of parts before assembling while waiting for them to be assembled with other parts that make up the assembly unit.

Inter-exchange breaks - non-working hours due to work schedule include:

P cm - breaks between shifts;

P on - lunch breaks;

VD - days off;

PD - holidays;

A distinction is made between the production cycle of a simple process — the cycle of manufacturing a part or blank, and the complex process — the cycle of manufacturing a product or assembly unit.

Methods for determining the duration of the production cycle for these two cases are different.

Comments

To leave a comment

Management

Terms: Management