Lecture

The main goal of the RPP system is to organize the movement of the objects of labor in production that are coordinated in time and space.

The criteria for achieving the objectives of the RPF are:

The most important strategic criterion for evaluating the system of industrial activity is the organization and maintenance of the rhythm of production and the uniformity of work of all departments and services of the company. Achieving this criterion means a coordinated, interrelated work of the main production units, technical and support services for the implementation of the current plan, built on the basis of a previously developed production schedule.

To assess compliance with the established in the calendar schedules of volumes and terms of production in natural terms, indicators of rhythm and uniformity of output are used.

Rhythm characterizes the degree of accuracy of the performance of planned tasks for the individual periods of time for which they (tasks) are set.

Uniformity characterizes the degree of equality of production volumes, produced in equal segments of working time.

As can be seen from the formulation of the rhythm indicator, it is applicable only to actual data and can be determined if there are deviations from the planned targets, which will characterize the coefficient (level) of rhythm. (For example, calculating the coefficient of rhythm for a decade requires the size of deviations from daily plans.)

In practice, in many industrial enterprises, rhythm is often determined by the specific gravity of the output of marketable products for a decade (ten-day period) in the total volume per month. In this work is recognized as rhythmic, if in each decade produced 1/3 of the monthly volume of production.

The method of calculating the coefficient of rhythm provides for taking into account deviations from the plan for individual periods of time. This takes into account either only negative deviations (underperformance), or both negative and positive (overtime).

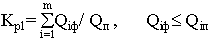

When taking into account only negative deviations, the coefficient of rhythm (K p1 ) can be determined by the formula:

When taking into account positive and negative deviations, the coefficient of rhythm (K p2 ) is determined by the formula:

where: Q p - the planned (monthly) volume of output in the accepted gauges; Q i p and Q i f - output for the i-th period of time (decade) according to plan and in fact.

Rhythm indicators for different types of production are expressed in different measures of time.

In mass production, rhythmicity is planned and taken into account for each item in accordance with the tact of the line or the hourly schedule of work.

In large-scale production, hour and shift-daily work schedules are used.

In mass production , daily-shift and five-day schedules are used.

In small-scale and single production :

in the manufacture of simple and low-labor products - five-day or ten-day work schedules;

in the case of complex products, rhythm indicators are set in accordance with the approved schedule of work.

As the practical experience of the enterprise shows, it is advisable to use the rhythm coefficient for evaluating the work of the workshops in a single and small-scale production, where the requirement of uniformity of output is not quite applicable to the specifics of the products produced.

In mass and large-scale production, to which the demand for equal output in equal periods of time can be justifiably made, the coefficient of uniformity should be an estimated indicator .

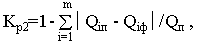

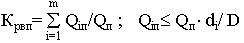

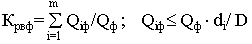

The method of calculating the coefficient of uniformity of output provides for the use to calculate the planned and actual production volumes, but not higher than the value that would have been with complete uniformity, i.e. in the distribution of output in proportion to the working time. To calculate the planned (K RVP ) and actual (K RVF ) uniformity coefficients, the formulas can be used:

Where:

D - the number of working days in the planning period (month); d i - the number of working days in the i-th period of time (decade); Q n ? d i / D and Q f ? d i / D - respectively, the planned and actual output for the i-th period of time (decade) under the condition of complete uniformity (the output is proportional to working days).

RPF is a complex system consisting of a set of interrelated elements or parts that form a complex whole. Certain relations are established between the elements in the system, which characterize the interrelation, orderliness and interaction of these elements, which is a concrete manifestation of the main principle of the system approach - the integrity of the system.

Based on the essence of the concept of "system" there are three defining aspects of the systems approach: functional, elemental and organizational. Evaluate the system of RPP using the defining aspects of the systems approach.

In accordance with the main goal, the complex of functional tasks solved by the RPO system includes three interrelated blocks of tasks:

The block of volumetric planning implements a set of tasks for the development of annual and quarterly production plans, supported by volumetric calculations of the load of each of the shops and sites. A comparison of the planned volumes with the actual capabilities of the units.

In the block of scheduling monthly schedules are developed with clarifications up to a decade of launch dates - the release of a batch of parts in production, additional volumetric calculations in the context of sections, loading indices of certain groups of equipment and jobs.

In the operational planning unit , tasks for each workplace are being developed for a shift (day), and operational execution, daily operational accounting, production control and regulation are also organized.

The elemental composition of the OPP system includes:

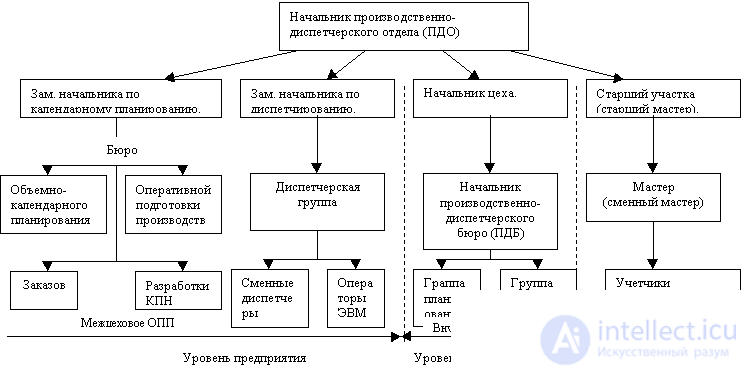

In organizational terms, the system of industrial-level education has a three-level structure: the levels of an enterprise, a workshop and a site. The approximate organizational structure of the company's OPP system is presented in Fig. 9.7.

Fig.9.7. Organizational structure of the company OPP system

At the enterprise level, the central production and dispatching department (PDO) solves a set of interdepartmental operational-production planning tasks, having for this bureau (groups) volume-scheduling, operational preparation of production, development of calendar-planning norms (CIT), orders and a dispatching group. At the workshop level, the production dispatch bureau (PDB) solves a complex of tasks of the intrashop operational production planning. PDB has a group of planning and control of production sites, as well as a group of shop dispatchers. At the site level, site managers, planning and dispatch personnel, and foremen solve a complex of tasks of intra-unit planning, determine and ensure the movement of objects of labor to workplaces and teams, carry out operational control and regulation of production.

The functional tasks of the PDO are:

The organizational structure of the RPO depends on:

In some cases, departments (bureaus) are created for the operational planning of individual industries. The production management hierarchy may include, in addition to the head of the PDO, the position of head of production, deputy general director for production, etc.

Regulatory support for OPP . To solve the functional tasks of volumetric and scheduling, the OPP system has a certain set of calendar-planning norms (CIT), which allow regulating the movement of products and their parts in production.

CPN are tools in the activities of line managers (heads of workshops, sites, craftsmen, etc.) and employees of planning services, without which it is impossible to establish the volume and timing of the planned work. The number and content of CIT is determined by the type of production.

1. In medium- and large-scale production, the main CITs include:

2. In small-scale and single production :

3. In mass production:

= J (pieces);

= J (pieces); Consider the definition of these norms on the example of mass production.

The initial norm, which determines the values of all other CPN in batch production, is the size of a batch of parts .

The size of a batch of parts is understood as the number of items that are simultaneously launched into production, moving on technological operations and worked at a single expenditure of preparatory and final time * on each operation.

Under the preparatory-final time refers to the time required for the development of a particular technological operation (familiarity with the drawing, tooling, tools, setting up the first part, etc.).

Lot size has a different impact on the production economy.

An increase in lot size contributes to an increase in labor productivity, a reduction in the share of preparatory and final time * and a reduction in conditionally fixed costs per unit of production. At the same time, an increase in batch size has a negative impact on the enterprise’s economy, since it entails an increase in the duration of the production cycle and the binding of working capital in work in progress.

The optimum batch size is considered to be the minimum cost per detail.

In practice, they use simplified methods for calculating the size of a batch of parts.

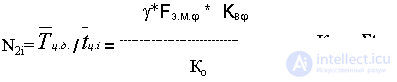

In the conditions of technologically specialized sites, the batch size is determined by operations with complex equipment setup using the formula:

where: t пз - preparatory-final time * for a batch of parts, min; t W - the rate of time to perform the operation, min;  - coefficient of allowable time for changeover (from 0.02 for large-scale and up to 0.1 for small-scale production).

- coefficient of allowable time for changeover (from 0.02 for large-scale and up to 0.1 for small-scale production).

On exploded group plots and lines using the method of phased calculations and approvals. It is proposed to consider the procedure for calculating the parameters based on the monthly program.

Step 1. Calculate two maximum permissible parameters of the desired batch size n 1i and n 2i . Both of them depend on the main parametric characteristic  K plot

K plot  that determines the average period of continuous employment of its jobs processing one batch of parts T nz

that determines the average period of continuous employment of its jobs processing one batch of parts T nz  and the allowable duration of its production cycle T CDD i .

and the allowable duration of its production cycle T CDD i .

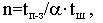

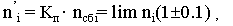

The parameter n 1 i is determined by the formula:

Where:

- t i is the average operational processing time of the i-th part;

- F em  effective monthly time base

effective monthly time base  -th plot, min;

-th plot, min;

- K in  average rate of compliance

average rate of compliance  th site.

th site.

The parameter n 1i reflects the level of specialization of workplaces achieved by the site, labor productivity indicators and cost of processing.

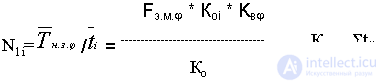

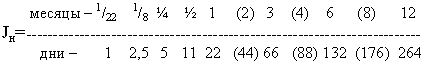

The parameter n 2i is determined by analogy:

Where:  cycle limiting factor, for complex and time-consuming parts

cycle limiting factor, for complex and time-consuming parts  = 1.0; for parts of average complexity - 0.75; with limited storage reserves and delivery periods - 0.5 or 0.25; K m.o. the coefficient of interoperable idleness, when the number of operations K about

= 1.0; for parts of average complexity - 0.75; with limited storage reserves and delivery periods - 0.5 or 0.25; K m.o. the coefficient of interoperable idleness, when the number of operations K about  3 K m.o. = 3, with K o = 4 - 10 K m.o. = 1.5 and when K o

3 K m.o. = 3, with K o = 4 - 10 K m.o. = 1.5 and when K o  11 K m.o. = 0.75.

11 K m.o. = 0.75.

The parameter n 2i takes into account and limits the allowable amount of work in progress and the binding of working capital.

Stage 2 . Adjust the smallest (limiting) of the received preliminary batch sizes (lim n i ) in order to comply with the requirements of the technical-organizational order. The main thing is to ensure the multiplicity of the batch of i-parts to the size of the batch of products at the assembly stage n sat i and the monthly production program N m i .

The multiplicity of the batch of parts to the size of the assembly batch of products is ensured by the selection of such a value of the multiplicity factor K n = 1, 2, 3?

The multiplicity of the batch of parts for the monthly program is ensured by establishing for the batch of the i-th parts the normal frequency of repetition of its production J.

Under the period of repetition of production or rhythm of the party refers to the length of time between the launch or release of two adjacent batches of this product.

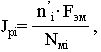

In general, the calculated frequency of repetitions of the i-th parts:

where: N m is the monthly program for the production of i-parts.

The obtained value of J pi is consistent with the number of preferred values of periodicity adopted in the practice of calendar and regulatory calculations:

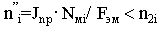

For the accepted frequency of repetition of production of the i-th parts J npi take the value closest to J n . After that, a second batch size correction of the i-th parts is performed according to the condition:

If the condition is satisfied, n 'is taken as the final value of n i that meets all the requirements.

In practice, additional conditions for limiting the size of a lot are often its conformity:

Timing advance launch and release items. In the production process, an important point is the observance of the principle of timeliness of the beginning and end of work both on a separate part and on stages of production.

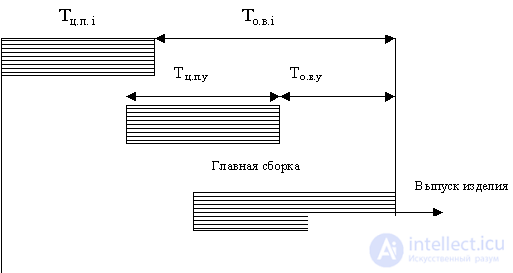

Для определения сроков опережения запуска отдельных деталей, узлов и стадий производства необходимо построить взаимоувязанные цикловые графики с учетом окончания работ по каждой из них и по отношению к сроку выпуска готовой продукции.

Срок опережения запуска i-х деталей в производство (Т с.з ) по соответствующей стадии производства определяют согласно схеме, представленной на рис. 9.8, по формуле:

Т с.з.i = Т ц.п.i + Т о.в.i ,

где: Т ц.п.i - цикл производства i-й стадии; Т о.в.i - опережение выпуска (завершения) i-й стадии.

Fig. 9.8. Схема формирования сроков опережения запуска-выпуска.

Незавершенное производство. Под незавершенном производством понимаются начатые, но не законченные изготовлением изделия или их части, находящиеся на разных стадиях производственного процесса, а также их складские запасы.

Незавершенное производство подразделяется на внутрицеховое и межцеховое (складское).

Внутрицеховые остатки незавершенного производства образуют предметы, находящиеся в процессе обработки (сборки), в транспортировке, на контрольных пунктах, у рабочих мест и в цеховых кладовых в ожидании продолжения производства.

Межцеховые остатки незавершенного производства образуют предметы, прошедшие одну из стадий и пролеживающие на складе в ожидании потребления их на последующей стадии.

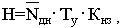

Общая закономерность формирования незавершенного производства (Н) выражается зависимостью:

Where:

N дн - среднедневной выпуск данных предметов в принятых единицах измерения;

Т ц - длительность цикла изготовления данных предметов, дней;

К нз - коэффициент нарастания затрат (0,5-0,75).

При планировании и контроле уровень незавершенного производства может выражаться в натуральных единицах как фактор, определяющий ритмичность выпуска и равномерность производства; в трудовых единицах как показатель изменения длительности производственного цикла изделий; в стоимостных - как показатель соблюдения предприятием лимита оборотных средств.

Содержание объемного планирования производства. Цель объемного планирования - обеспечить рациональное построение производственной программы для предприятия и цехов на годовых, квартальных и месячных отрезках времени.

Объемный план содержит две части: директивную и объемную. В директивной части перечисляются номенклатура и число изделиq по программе, сроки их выпуска, трудоемкость и стоимость изделий.

Объемные расчеты бывают предварительными и уточненными . В обоих случаях по производственному подразделению (цеху, участку, бригадам, рабочим местам) последовательно определяют потребные на выполнение программы ресурсы; устанавливают располагаемые ресурсы; затем их сопоставляют и балансируют.

Предварительные объемные расчеты подкрепляют разработку годовых и квартальных производственных программ предприятия и цехов.

Содержание календарного планирования производства. Главной целью календарного планирования является установление взаимосвязанной совокупности сроков начала и окончания производства по всей планируемой в данный период номенклатуре изделий. При разработке календарного плана должны быть реализованы четыре основных принципа:

Построение межцехового календарного плана ставит своей целью установление взаимосвязанной системы сроков движения изделий и их частей по стадиям и операциям межцехового технологического процесса. Решение этой задачи достигается путем применения различных систем планово-учетных единиц (ПУЕ) * .

Под планово-учетной единицей понимается совокупность элементов продукции, сформированная с учетом специфики ее планирования, изготовления и комплектования для дальнейшего использования или реализации.

В основе создания планово-учетной единицы лежит деталь и комплект, применительно к которым и определяются сроки начала и окончания их производства в цеховых календарных планах.

In accordance with the adopted planning and accounting unit usually distinguish and interdepartmental scheduling system. In industrial practice, the following planning systems are distinguished according to the adopted planning and accounting unit:

The use of planning and accounting units in various systems of inter-shop scheduling is presented in Table. 9.1.

The use of various scheduling systems in the PUC.

T a b and c a 9. one

OPP system | Planning and accounting units | Type of production | |

For the enterprise as a whole | By individual workshops | ||

| Showy | Order | Kit parts and assembly units | Single |

| Warehouse | Regulatory batch replenishment | Order lot | Small batch |

| Machine complete | Product N | Parts Kit N | Serial |

| По ритму выпуска | Изделие | Партия деталей | Массовое |

| Подетальная | Партия деталей | Партия деталей | Массовое |

Рассмотрим содержание наиболее распространенных систем календарного планирования.

1. При показной системе наиболее распространенной в единичном производстве, по каждому заказу составляются либо ленточные графики Ганта, либо объемно-цикловые графики, отражающие по цехам объем работ и сроки выполнения заказа. В случае большой сложности заказа, многочисленности работ и исполнителей применяют метод сетевого планирования.

2 При серийной по опережениям системе ритмичность работы всех звеньев производства достигается путем распределения работ по отдельным плановым периодам. Причем осуществляется комплектное календарное опережение технологических стадий производства. ПУЕ при этой системе является серия одноименных изделий, подлежащая совместному изготовлению в конкретный плановый период (часто месяц). Если серия состоит из разных изделий, изготовление проводят в определенной очередности или параллельно. Основным условием успешности производства является полное обеспечение изготавливаемых изделий комплектом деталей к началу сборки.

При такой системе для разработки оперативно-производственных заданий цеха на предстоящий период осуществляют "привязку" установленных нормативов по каждой серии изделий к определенным календарным периодам (в месяцах). Исходным моментом в этом случае является установление очередности сборки и выпуска изделий. Обязательно учитывается состояние заделов незавершенного производства.

После построения графика сборки устанавливается программа изготовления деталей механическим цехам в предшествующие месяцы и производство заготовок в заготовительных цехах по отношению к механическим цехам с учетом принятого календарного опережения .

3. Система "на склад" обычно используется при планировании производства унифицированных и стандартизованных изделий. Она предусматривает ведение карточек складского учета по каждому наименованию изделий, в котором устанавливаются три уровня запасов деталей: минимум, максимум и точка заказа.

4. При машинно-комплектной системе производственные задания цехам устанавливаются в комплектах деталей на конкретные изделия. В программе цехов указываются порядковый номер каждого изделия и срок сдачи комплекта деталей.

5. Система по ритму выпуска применяется на предприятиях с массовым производством и его поточной организацией. Производственные цехи получают задание по выпуску деталей с учетом заделов по ним на основе стандартных графиков сборки изделий. При этой системе производится синхронизация всех звеньев производства: отдельных рабочих мест, автоматизированных линий и поточных участков путем выравнивания их производительности относительно единой расчетной величины - такта поточной линии. Основной ПУЕ * при планировании по ритму выпуска является деталь, а в заданиях механосборочным и выпускающим цехам - готовое изделие. Указанная система базируется на следующих нормативно-календарных расчетах движения производства:

Целесообразность и эффективность применения той или иной системы планирования определяется спецификой производства и задачами, стоящими перед предприятием.

Comments

To leave a comment

Management

Terms: Management