Content and tasks of technological preparation of production. Technological preparation of production (CCI) - is a set of interrelated works that ensure the technological readiness of the enterprise to produce products of a given level of quality at the established time, volume of production and costs.

CCI is a time consuming and expensive process. The cost of technological equipment in the cost of production is: small-scale and single production - 5-8%; serial - 10-18%; mass - 20-25%.

The most important tasks of the CCI are:

- design * and development of new and improvement of existing technological processes of manufacturing products and their parts;

- the creation of prerequisites for the introduction of progressive methods and forms of organization of production and labor;

- mechanization and automation of production processes.

Functions, elemental composition and organization of the construction of the CCI. The work on the CCI at the enterprises is usually carried out by the departments of the chief process engineer, welder, metallurgist and shop technological bureaus.

The degree of detail of the CCI depends on:

- type of production;

- degree of complexity of the product;

- product responsibility.

The process of the Chamber of Commerce and Industry includes the following basic blocks of tasks (stages).

- Processing of product design and parts for manufacturability. It is carried out before the development of technological processes, the main objects: materials, rationality of structures, assemblies, etc.

- Development of interdepartmental technological routes (overhaul). Distribution of parts and assemblies between workshops and sites according to the sequence of types of processing (foundry, forge, welding, machining, etc.).

- Development of technological processes , i.e. content and sequence of operations in the manufacture of objects. In this case, depending on the type of production, the corresponding detailing of the elements of the technological process is carried out. In the development of technological processes takes into account the possibility of unification of processes: typical or group processing. Typical unification provides for a common operating route for processing a number of parts (turning-turning-grinding-milling-drilling). Group unification provides for grouping parts according to the generality of surfaces to be machined, basing, etc., creating a special group tooling.

- The establishment of operational time standards. Norms are usually established by a technologist-norm setter, who, depending on the type and conditions of production, can establish one of the following types of norms:

- regulatory (reference books on rationing);

- calculated and analytical;

- experimental statistical (cumulative statistical data).

- The establishment of norms of consumption of materials on the part or assembly (assembly).

- Design and manufacture of technological equipment , including special machining and measuring tools (fixtures, conductors, dies, molds, tools, etc.).

- Debugging and introduction into production of developed technological processes . Two main tasks are being solved: the process of mastering a new production; check of compliance: selected equipment, equipment, tool and its quantitative need, measuring instrument, the need for space and human resources.

- Metrological examination of the CCI. Verification of compliance of the provision of selected measuring instruments with the requirements specified in the technical specifications (TU) for the specified products.

To perform functional tasks of the CCI, its elemental composition includes:

- human resources (managers, specialists, technical performers);

- material resources (basic and auxiliary materials, stationery, etc.);

- technical means (computers, multiplying and other office equipment);

- economic and mathematical software (algorithms and programs for ASTPP, various mathematical methods, etc.);

- information support (standards, classifiers, norms and standards, etc.).

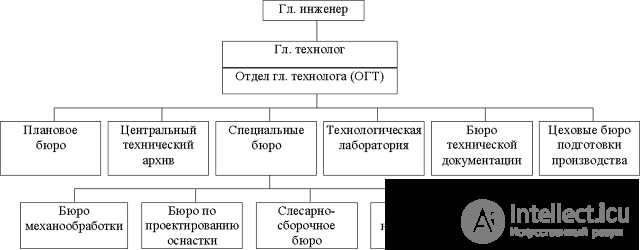

The typical organizational structure * of the service of the Chamber of Commerce and Industry of the instrument-making enterprise can be represented in the form of the following diagram (Fig. 7.4).

Fig. 7.4. Typical scheme of the structure of the subsystem of the CCI.

There are three forms of organization of the CCI:

- centralized

- decentralized

- mixed

- Centralized - typical for serial, large-scale and mass production.

The development of technical processes is carried out in the OGT, the introduction of processes and control over the observance of technological discipline - workshop bureaus of production preparation (BPP).

- Decentralized - typical for small-scale production.

Development of technological processes and their implementation - BPP workshops, GBS - the development of interdepartmental routes, control and assistance in the implementation of processes.

- Mixed - typical for mass production.

Centralized form of the Chamber of Commerce and Industry - for a constant product range, decentralized - for products of a one-off nature (technical services to third parties, etc.)

The main directions of acceleration of the Chamber of Commerce and Industry in instrument making are:

- Maximum parallel execution of all stages of the CCI;

- Unification of technological processes, the use of group technological equipment;

- Maximum automation and computerization of the CCI processes.

Comments

To leave a comment

Management

Terms: Management