Lecture

Quartz resonator , jarring. Quartz is a device in which the piezoelectric effect and the phenomenon of mechanical resonance are used to build a high-quality resonant element of an electronic circuit.

Despite the fact that instead of quartz, other piezoelectrics are often used, for example, ceramics (Ceramic resonator), the adjective “quartz” is commonly used for all such devices.

In modern electronics, especially in digital it is difficult not to find an electronic component called a quartz resonator. At its core, a quartz resonator is an analogue of a collective electric circuit based on capacitance and inductance. However, the quartz resonator exceeds the LC circuit in very important parameters.

As is known, the collar circuit is characterized by good quality. Quartz-based resonators have a very high Q-factor, which is unattainable when using an ordinary oscillatory LC-circuit. If the Q-factor of ordinary circuits is within 100 - 300, then for quartz resonators the value of Q-quality reaches 105 - 107.

The capacitance of a capacitor is quite dependent on the ambient temperature. Capacitors even have a parameter called TKE (temperature coefficient of capacity). It shows how much the capacitance of a capacitor changes with a change in temperature.

Naturally, when using a capacitor as part of an LC circuit, its frequency *** will depend very strongly on the external temperature of the medium. The same applies to inductance, which also has its own temperature characteristic - TKI.

It is clear that for use in digital technology (including communication technology) a more stable and reliable source of harmonic lines is required.

Quartz-based resonators have a very high temperature stability. It is because of the high quality and temperature stability that quartz resonators are used in radio engineering very actively.

Any processor or microcontroller runs at a certain clock frequency. It is clear that a generator is required for setting the clock frequency. Such a generator, as a rule, uses a quartz resonator as a source of high-precision harmonics. In those schemes where high quality is not required, ceramic-based resonators - ceramic resonators can be used. The quality of resonators based on piezoelectric ceramics is not more than 103. They can be found in remote controls, electronic toys, household radios.

The principle of operation of the quartz resonator relies entirely on the piezoelectric effect. The basis of any quartz resonator is a plate of quartz. Quartz is one of the varieties of silica SiO2. Only low-temperature quartz, which has piezoelectric properties, is suitable for the manufacture of resonators. In nature, such quartz is found in the form of crystals and shapeless pebbles. For the manufacture of resonators using both natural and synthetic quartz crystal.

Optical and piezoelectric synthetic quartz is used in engineering, including personal computers, optics and telemetry, digital video cameras and cameras, radio and telecommunication devices, remote control and automatic control systems, radar and radio navigation equipment, for high quality substrates, as well as in the watch industry.

Synthetic quartz grown by the hydrothermal method is widely used in the jewelry industry, its particular colored varieties.

Properties of synthetic quartz

Chemical formula: SiO2

Hardness (Mohs scale): 7

Density: 2.65

Refractive index: 1,544 - 1,553

Dispersion: 0.013

Crystal lattice: trigonal

Dielectric constant: 4.5

Phase transition temperature: 573 ° C

| Quartz plates |

|---|

|

|

||

|

Quartz crystal

|

Chemically, quartz is very stable and does not dissolve in any of the acids, except hydrofluoric. Quartz is also very solid. On the scale of hardness, he ranks seventh out of ten.

To make a quartz plate, a quartz crystal is taken and a plate is cut from it at a certain angle. The electromechanical properties of the quartz plate depend on the angle at which the cut occurs. The type of cut significantly affects temperature stability, the number of parasitic resonances, the resonant frequency.

Next, a metallized layer (made of silver, nickel, gold or platinum) is applied to the two sides of the quartz plate and fixed by means of rigid wire contacts in a quartz-holder. All this design is placed in a sealed enclosure.

Quartz resonator in the crystal holder

The quartz resonator is an electromechanical ring system. As is known, any collective system has its own resonant frequency. The quartz resonator also has its nominal resonant frequency. If an alternating voltage is applied to the quartz plate, which coincides with the resonant frequency of the quartz plate itself, then a frequency resonance occurs and the amplitude of colo *** s increases sharply.

At resonance, the electrical resistance of the resonator decreases. The result is the equivalent of a sequential numbering system. Since the energy losses in the quartz resonator are very small, it actually represents an electric electric circuit with a very high Q.

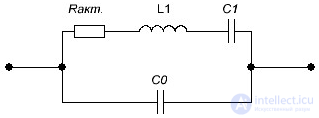

The equivalent circuit of a quartz resonator is shown in the figure.

|

|

Equivalent circuit of a quartz resonator |

Here C0 is a constant (static) capacitance formed by metal plates-electrodes and the holder. Series inductance L1, capacitor C1 and resistance Ract. reflect the electromechanical properties of a quartz plate. As we see, if we discard the capacity of the assembly and the quarterer C0, then we obtain a consistent loop *** body contour.

When installing a quartz resonator on a printed circuit board, you should take care not to overheat it. This recommendation is probably due to the fact that the design of the quartz resonator is quite thin. Temperature overheating can cause deformation of the quarter-holder and plate-electrodes. Naturally, all this can affect the quality of the resonator in the circuit.

It is also known that if the quartz is heated above 5730 C, then it turns into high-temperature quartz and loses its piezoelectric properties. Of course, it is impossible to bring the temperature of quartz to such a temperature with soldering equipment.

On a plate, ring or bar, cut from a quartz crystal in a certain way, 2 or more electrodes are applied - conductive strips.

The plate is fixed and has its own resonant frequency of mechanical collars ***.

When voltage is applied to the electrodes, due to the piezoelectric effect, bending, compression, or shear occurs, depending on how the piece of the crystal is cut.

However, the oscillating plate, as a result of the same piezoelectric effect, creates a counter-emf in the external circuit, which can be considered as a phenomenon equivalent to the operation of an inductance coil in a collar circuit.

If the frequency of the applied voltage is equal to or close to the frequency of its own mechanical collars of the *** plate, the energy costs of maintaining the collars of the plate are much lower than with a large frequency difference. This also corresponds to the behavior of the collective contour.

On schematic diagrams and in technical documentation, a quartz resonator is denoted like a capacitor, only a rectangle is added between the plates, which symbolizes a quartz plate. Next to the graphic is the letter Z or ZQ.

|

|

Symbol of the quartz resonator on the schemes. |

Many novice radio amateurs wonder: “How to check the quartz resonator?”

Unfortunately, reliably check the quartz resonator can only replace. The cause of the failure of the quartz resonator can be a strong blow or a fall of the electronic device in which it was installed. Therefore, if there is a suspicion that the quartz resonator is in good condition, then it should be replaced with a new one. Fortunately, in the repair practice, the failure of a quartz resonator is rare, of course, there are exceptions, but they belong to portable electronics, which are often dropped.

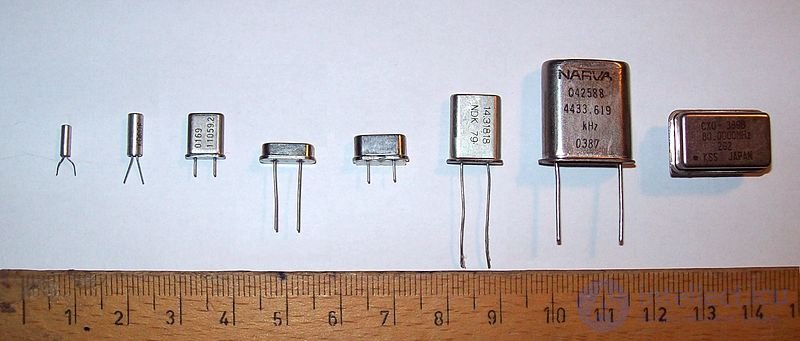

Quartz resonator in an airtight glass case of the fingerless baseless execution

4 MHz resonator in a miniature metal sealed enclosureHC-49 / US

Metal enclosures of various sizes

The piezoelectric effect was first discovered by the brothers Jacques and Pierre Curie in 1880. Paul Langevin was the first to use this effect in the watch resonator of the sonar before the First World War. The first crystal resonator operating on salt salt was manufactured in 1917 and patented in 1918 by Alexander M. Nicholson of Bell Telephone Laboratories, although this was disputed by Walter Guyton Cady, who made the quartz resonator in 1921. Some improvements in quartz resonators were introduced later by Lewis Essen and George Washington Pierce.

The first frequency stable quartz resonators were developed in the 1920s – 30s. Since 1926, quartz resonators on radio stations have been used as frequency-bearing elements. At the same time, the number of companies that started producing quartz resonators increased dramatically; only until 1939, more than 100,000 units were released in the United States.

One of the most popular types of resonators are resonators used in clock circuits. The resonant frequency of the clock resonators 32768 Hz, divided into a 15-bit binary counter, gives a time interval of 1 second.

They are used in generators with a fixed frequency, where high frequency stability is required. In particular, in the reference oscillators of frequency synthesizers and in transceiver radio stations for generating a DSB signal at an intermediate frequency and detecting SSB or a telegraph signal.

Also used in quartz bandpass filters of intermediate frequency superheterodyne receivers. Such filters can be performed on a ladder or differential circuit and are distinguished by a very high quality factor and stability compared to LC filters.

By type of housing, quartz resonators can be output for surround installation (standard and cylindrical) and for surface mounting (SMD).

The quality of the circuit, which includes quartz resonators, determine such parameters as the frequency tolerance (frequency deviation), frequency stability, load capacity, aging.

NDK actively cooperates with manufacturers of microcontrollers, various chipsets and modules, and also conducts continuous close work with end customers who use various chipsets and quartz products in their products. Their experience in the production of quartz products, as well as the experience of cooperation with the manufacturers of chipsets and modules, NDK is ready to offer its customers to facilitate their work on the selection of components for their products. NDK has two laboratories - one in Japan based on a factory in Sayama and the other in Germany in Sinsheim, where, in collaboration with the largest manufacturers of microprocessors and chipsets, it does a great job of conducting tests aimed at achieving the best compatibility of quartz NDK components with microchips leading manufacturers (IC matching test).

Quartz resonators connected to various microcircuits, microprocessors, LSI / VLSI (LSI / VLSI) are, in a sense, "conductors" controlling many thousands of logic elements, therefore the quality of the joint operation of the microcircuits and the resonators connected to them is important for the operation of the entire device (device, system) in general.

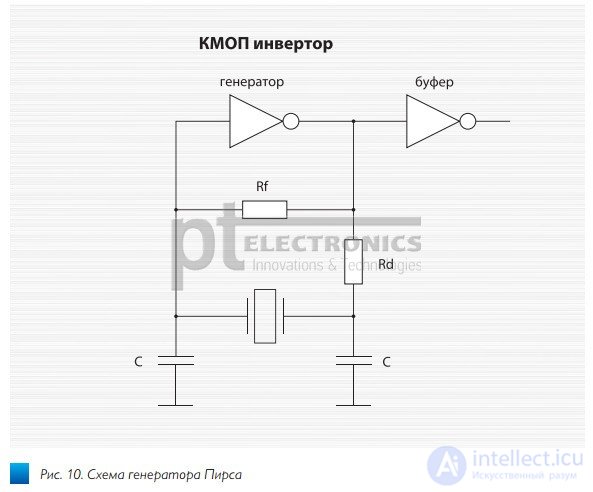

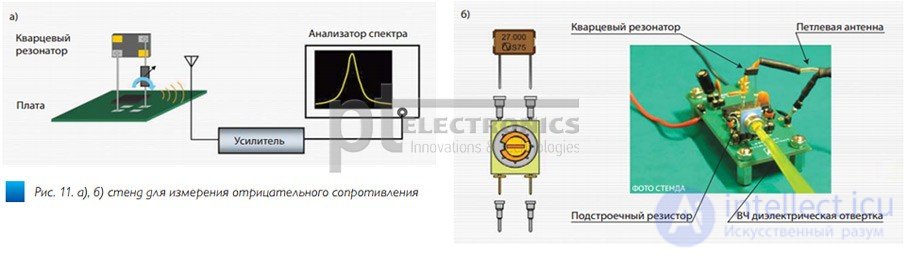

To ensure stable operation at specified frequencies of internal clock oscillators of microcircuits with external quartz resonators, it is necessary to choose the nominal values of external components, generally connected to the resonator according to the scheme shown in fig. 10. The inverting amplifier and buffer shown in the diagram are internal elements of the microcircuits. In some cases, the resistor Rf may not be installed, and instead of the resistor Rd, a jumper is installed, sometimes installation and capacitors are not required at the input or output of the generator. При работе в штатном режиме кварцевый резонатор и конденсаторы образуют П-образный фильтр, обеспечивающий фазовый сдвиг 180°, необходимый для запуска генератора на частоте, определяемой резонатором (так называемая схема генератора Пирса).

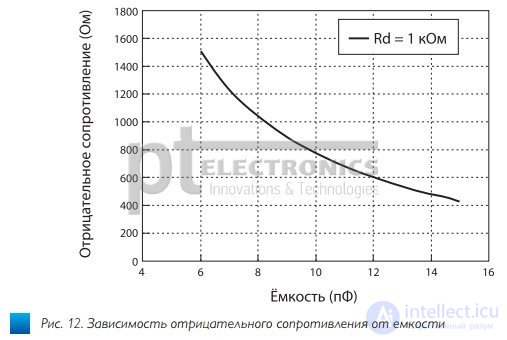

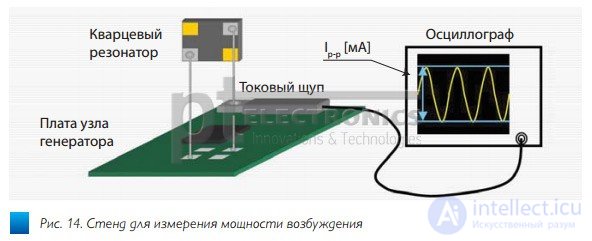

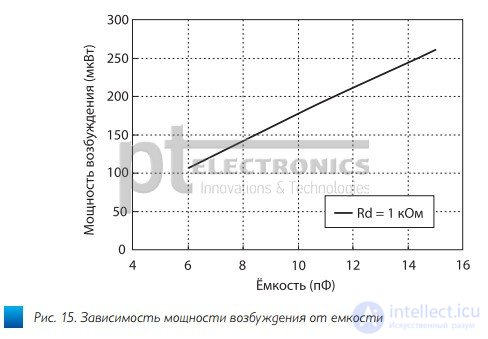

При проведении тестов на совместимость микросхем компания NDK экспериментально определяет параметры, имеющие важнейшее значение для стабильного запуска и функционирования кварцевого резонатора в составе конкретных микросхем при определенных условиях.

Как уже было сказано, в лабораториях NDK постоянно проводится ряд тестов по определению типов кварцевых резонаторов, в наибольшей степени подходящих для использования совместно с микропроцессорами и БИС основных серий таких компаний, как STM, TI, Microchip, NXP, Renesas и др.

В результате NDK имеет и готовы предоставлять своим клиентам данные по одобренным и рекомендованным компонентам NDK для работы с теми или иными чипсетами и модулями.

Также NDK предлагает своим клиентам провести тесты плат заказчика в своих лабораториях, на основе которых NDK даст свои рекомендации по работе чипсета и частотозадающих элементов в конкретной схеме заказчи

Comments

To leave a comment

Electronics, Microelectronics, Element Base

Terms: Electronics, Microelectronics, Element Base