Lecture

The processes of automatic control systems are three main groups of requirements:

Requirements for accuracy in steady state.

Stability requirements.

Requirements for the quality of transients.

In addition to these systems, in practice, there are also technical and economic requirements related to the specifics of the control object or technological process.

In our course, we will consider only the requirements for the quality of transients, the dynamics of systems, as a question not only closely related to mathematical modeling of systems, but also related to the use of a diverse mathematical apparatus. Requirements for accuracy in steady-state modes and requirements for sustainability will be considered in the disciplines "Theory of Automatic Control", "Control Systems for Electric Drives", "Automation of typical production processes and industrial installations".

In industrial installations with automatic control systems, two large groups can be distinguished:

Installations in which the transient time is negligible compared to the steady state. In these cases, dynamic modes do not have a significant impact on product quality or equipment performance, for example, pumps, fans, conveyors, etc.

Installations in which the time of the transition process is commensurate with the time of steady-state modes, or, in which the deviation of the controlled variable in the dynamics significantly affects the quality of products, for example, machines, robots, tracking systems, etc.

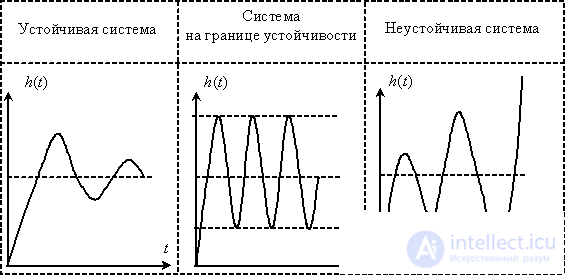

Stability, that is, the ability to decay transients, is a necessary but far from sufficient condition for the practical suitability of systems. This criterion allows a very rough estimate of transients. Consider how the transitional characteristics for the three main modes in terms of stability.

Fig. one

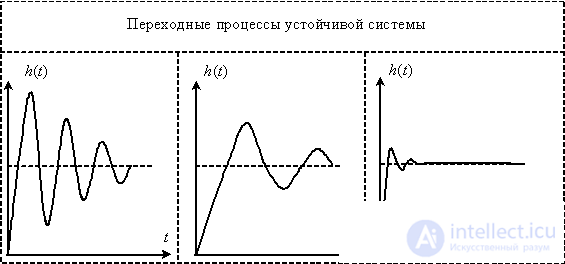

Using as shown in fig. 1, the stability criterion in terms of the transient response (transient), we can say that the system is stable if the transient is attenuated. However, the system may be stable, but its transients, depending on the change of parameters, will vary greatly, as shown in Fig. 2

Fig. 2

We see that these processes differ significantly in appearance; they have different oscillation frequencies, completion time, deviation amplitude from a given value. In this regard, it is necessary to compare, assess the stable temporal characteristics of systems.

It should be noted that specialists are interested not only in transients when changing control actions, but also transients in changing disturbing effects.

Thus, an important concept for control systems is the concept of the quality of transients, that is, the very nature of the flow of processes becomes important, especially factors such as duration, oscillation and dynamic deviation of the controlled variable from a given value.

To assess the quality of transient processes, characteristics, criteria or quality indicators are required that can be expressed numerically.

Quality criteria have the following applications:

Comparative analysis of automatic control systems when changing the parameters of the control object, or when comparing different types of systems for the same control object.

Synthesis, the choice of parameters of automatic control systems that provide the specified criteria for the quality of transients, the requirements of the technical specifications for the development of the system.

It is known that the transition process in the control system depends not only on the properties of the system itself, but also on the nature (type) of the input action. Therefore, the behavior of the system in assessing the quality of transient processes is considered under typical external influences. As such typical effects are most often used:

a single step function, less often, a linearly growing signal,

impact harmonic function.

Quality ratings are divided into two groups:

Direct quality indicators of transient processes. They directly characterize the transition process itself, the response of the system to a typical effect, most often, on a single step function.

Indirect indicators (criteria) of quality. They evaluate the quality of transients by other system characteristics, such as frequency characteristics, the nature and location of the roots of the characteristic equation (transfer function poles), and the integrals of the time function of the transition process.

Assessment of the quality of the transition process under the influence of the step function

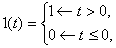

Direct quality assessment is determined by the graph of the transition characteristics of the control system  , that is, when a single step function is affected by the system -

, that is, when a single step function is affected by the system -

and at zero initial conditions, or on the transition curve of the controlled variable  when exposed to the input of the step function with an amplitude corresponding to the nominal or other specific value of the controlled variable.

when exposed to the input of the step function with an amplitude corresponding to the nominal or other specific value of the controlled variable.

Consider a control system with a unit negative feedback, the block diagram of which is shown in Fig. 2

Fig. 3

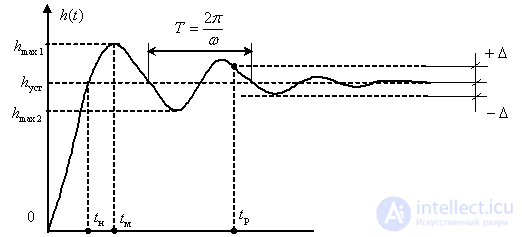

The system receives a stepped signal at the output, the system’s response can be observed at the output; in addition, a change in the control error can be considered as a transient process

.

.

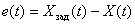

Exemplary graphs of output signal changes and control errors are shown in Fig. 2, respectively. 4 and 5.

Fig. four

Fig. five

Consider the direct assessment of the quality of transients, shown in Fig. 4 and 5:

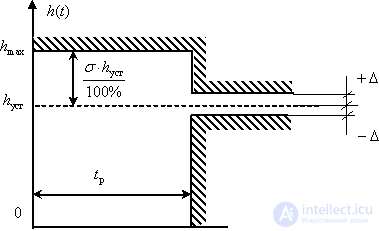

- the minimum time after which the regulated value will remain close to the steady-state value with a given accuracy -

- the minimum time after which the regulated value will remain close to the steady-state value with a given accuracy -

.

.

pre-set as a percentage of the steady-state value

pre-set as a percentage of the steady-state value  where there are no specific requirements - accept

where there are no specific requirements - accept  .

.

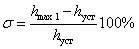

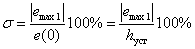

- override - the maximum deviation from the steady-state value, expressed in relative units or percents -

- override - the maximum deviation from the steady-state value, expressed in relative units or percents -

or

or  .

.

Regulatory requirements are usually  , sometimes the quality of the process may be required

, sometimes the quality of the process may be required  , for example, in positioning systems of industrial robots manipulators.

, for example, in positioning systems of industrial robots manipulators.

- oscillation frequency -

- oscillation frequency -

,

,

Where  - oscillation period for oscillatory processes.

- oscillation period for oscillatory processes.

- is the number of full oscillations that has

- is the number of full oscillations that has  or

or  during regulation

during regulation  , the usual requirements for the number of oscillations

, the usual requirements for the number of oscillations  Some systems impose a limitation on oscillation.

Some systems impose a limitation on oscillation.  For example, in systems with significant backlash in mechanical gears.

For example, in systems with significant backlash in mechanical gears.

- time to reach the first maximum.

- time to reach the first maximum.

- the time of the rise of the transition process, the time from the beginning of the transition process until the first intersection of the steady-state line by the graph.

- the time of the rise of the transition process, the time from the beginning of the transition process until the first intersection of the steady-state line by the graph.

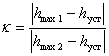

- damping factor equal to the ratio of the modules of two adjacent adjustments -

- damping factor equal to the ratio of the modules of two adjacent adjustments -

.

.

The indicators listed above can be supplemented by others if specific technical specifications for the development or study of control systems require it.

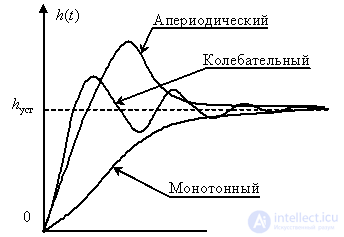

Stable transient processes that occur during step exposure, can be divided into three groups:

Monotone processes. Such processes, where the first derivative of the output value over time does not change sign.

Aperiodic processes. Here the derivative changes the sign no more than once.

Oscillatory processes. The derivative changes its sign periodically

In fig. 6 shows an exemplary view of the oscillatory, aperiodic and monotonic processes.

Fig. 6

Requirements for the quality of the transition process can be represented graphically. They boil down to the requirement that the deviation of the regulated value under step exposure does not go beyond the boundaries of a certain area shown in the process quality diagram. The simplest diagram is shown in Fig. 7

Fig. 7

A refined diagram in which restrictions are imposed on the rate of increase of the signal is shown in Fig. 8. On a refined chart  denotes the lag time, equal to the time interval concluded between the moments of application of the hopping signal (

denotes the lag time, equal to the time interval concluded between the moments of application of the hopping signal (  ) and the point in time at which the output value reaches half of the steady-state value.

) and the point in time at which the output value reaches half of the steady-state value.

Fig. eight

Test questions and tasks

In which systems of automatic control is the nature and parameters of the flow of transients important?

List the main areas of application of the quality criteria.

What quality indicators refer to direct indicators?

What quality indicators (criteria) are classified as indirect criteria?

How to determine the time of regulation on the schedule of the transition process?

How to determine the rearrangement of the transition process?

How to determine the rise time for the transition process?

What transients are referred to as aperiodic processes?

What transient processes are related to monotonous processes?

Comments

To leave a comment

Mathematical foundations of the theory of automatic control

Terms: Mathematical foundations of the theory of automatic control