Lecture

Introduction

Recently there is such a situation that the development of existing means of cooling microprocessors does not keep up with the increase in their thermal capacity. Modernization of technological processes that affect the power consumed by an individual transistor, in practice, does not effectively "thermally compensate" an increasing number of these transistors on a chip. And traditional CPU coolers barely cope with the cooling of new hot "stones".

By established standards, all semiconductor devices, which are characterized by an emitted power of less than 3 W, can operate without additional heat sinks. The microprocessors 8080, 8086, 80186, 80286 and 80386 worked perfectly without any coolers due to the fact that the power allocated by them was about the same 3 W, and they were tightly soldered to the motherboard, using it as an additional heat sink. The i80486 became the first "socket" processor for the PC, and it was the first who demanded specialized cooling (however, then there was a rather small cooler, roughly corresponding to the size of the cooling systems of modern low-end video cards). With the advent of the Pentium II, Intel has declared that the end of the world has come for a socket, it is impossible to make a lot of cheap cache on it, it does not provide adequate cooling, and now it’s time for the whole world to switch to slots. AMD followed and after socket 486, K5, K6, K6-2, K6-3 began to make the first slot K7 (Athlon). From the point of view of heat removal, the idea was, in general, not bad, but due to a number of reasons, after a couple of years, everything returned to the good old sockets. The power allocated by the processors steadily increased, the coolers evolved: the effective area of the heat sinks grew, the diameter of the fan increased, the speed of its rotation and, of course, noise, but nothing fundamentally new appeared.

Today, it is already unthinkable to imagine that a new processor may appear without announcing the characteristics of heat generation and power consumption. Why are there any complaints about the heat at all and why the processor cannot operate at a temperature of 200 degrees? Physics, of course. To begin with, the heat never had a positive effect on the reliability of electronic components. However, it is time to move on to more practical issues. However, first we will have to touch on some of the theoretical foundations of the subject and talk about the heat dissipation from the processor. For a start, we will focus on thermal grease and radiators.

Here, just in case, it is worth touching on the difference between heat and temperature. The radiator does not reduce the temperature of the chip! It simply increases the surface in contact with the air, thereby improving heat dissipation. Simple enough thing, but, for some reason, not always obvious. The radiator allows you to make the same processor for the air flow, roughly speaking, looks like a plate with an area not 100 square millimeters, but, for example, 1000. However, you will hardly allow anyone to claim such areas in the computer, that today's heatsink for powerful processors is a very small three-dimensional thing, whose equivalent in a two-dimensional form could sometimes stretch over the entire body area of your PC.

However, the area, whatever one may say, and how effectively you do not use the volume of the radiator, is still a limited resource. When it ends, the next protection step takes effect - the use of the heat-conducting properties of various materials. At one time, the standard in this area was aluminum, which coped well with the removal of heat from relatively cold chips until the end of the 90s.

However, over the years, one characteristic metamorphosis took place with the chips: their area was continuously reduced, and the temperature was also constantly growing. As a result, if earlier we dealt with a large chip under a large radiator, i.e., the heat source relative to the radiator was approximately evenly distributed over its entire area, and the air flow rate was relatively weak, since it was either the radiator itself on their own, or on a simple, weak fan. In such conditions, of course, aluminum was a good option.

Copper here was simply useless - a copper radiator would provide here about the same parameters, being three times harder, and also more difficult to process and more expensive. However, when the chips began to change in the manner described above, and the fans in the coolers began to become more powerful and powerful, the copper clearly began to pull ahead. With relatively high air flow rates, and a small chip area, the difference in thermal resistance of identical radiators made of copper and aluminum can be up to 30 percent. Although, of course, the threefold difference in weight remains.

However, there are more interesting materials in this sense. For example, various forms of carbon. From natural graphite to artificial diamonds, which have long been the norm in precision cooling systems for semiconductor lasers. In the PC, you can do with graphite, in all its forms: with a weight less than that of aluminum, its thermal properties more likely correspond to copper.

This is especially important given the current trend in the development of microelectronics — reducing the size of chips against the background of increasing their power and, accordingly, heat generation. So manufacturers of solutions for their cooling will have to use all the means at their disposal. And new materials, such as graphite, are likely to appear in radiators in the foreseeable future, and new forms that provide more efficient cooling.

With the agent itself - the air environment, it will not work. In terms of changing its physical properties, such as too low thermal conductivity. So you have to change the things that can still be changed - the heat transfer coefficient and the surface area involved in the heat exchange.

The coefficient of thermal conductivity can be changed in a whole set of different ways, where in the first place in terms of prevalence is an increase in the speed of air flow around the radiator. True, more than 10 meters per second, this parameter is usually not risky to raise - the cooler turns out to be too loud. Then the second factor available to the designers comes into play - variations with the shape of the radiators in order to increase the effective scattering area, while it is desirable to take into account the airflow configuration so that, for example, the air velocity does not decrease by a larger amount than the radiator area.

Here, however, also has its traditional methods. For example, a “hedgehog”, when on a square centimeter of the surface they try to place the maximum number of plates-needles, as a result of which the area in contact with the air increases as much as possible, but with an insufficiently effective design there are chances to significantly reduce the speed of the air flow through them. Every year the pressing technologies are improved, so that the density of the ribs to the same area is continuously growing, and their shape is continuously becoming more complicated - from the straight ledges here have long gone to curved planes of various configurations (Fig. 1).

Figure 1. Radiator with curved fins.

Air, as we have said, is not ideal for thermal conductivity, so that the best cooling requires another factor: that the radiator fits as closely as possible to the surface of the chip, and that even the smallest air gaps never appear between them. This requires either perfect polishing of their surfaces, or some kind of intermediary able to fill all the cavities and at the same time ensure decent heat transfer.

This, of course, is about a variety of pastes, gels, and the like. Today's materials of this kind have a thermal conductivity of up to 13 W / square meter / degree Celsius, which is more than enough for today's devices, but if the forecasts for the end of this decade come true, this parameter should increase threefold. But here there are no physical problems either - there is a potential above 100 W / square meter / degree Celsius, which means that chemists and physicists will probably move in this direction.

As they work, there will undoubtedly be the application of all new and new materials. As it was, for example, with materials with a changing phase state, described twenty years ago, but in cooling the chips that began to be used only when hot enough processors appeared, of the Pentium level. A changing phase state has, for example, water, which, depending on the temperature, can, without changing its chemical composition, change from one phase state to another - solid, liquid, gaseous.

Water, of course, is not used as an interlayer between the chip and the radiator, but there are other options, which are a mixture of polymer base and ceramic filler, which increases the thermal conductivity of mixtures - for example, Al2O3, BN, AlN or ZnO. Such mixtures at room temperature are a very viscous substance, in the interval of 40-70 degrees Celsius turning into a liquid state, displacing the air between the chip and the radiator, and reducing the thermal resistance of this area. In this state, materials with a changing phase state work no worse than gels and liquid thermal grease, but they are much more convenient to handle.

Air cooling, for all its disadvantages, has the main advantage - simplicity and low cost implementation. Certain improvements, however, make it possible to take a fresh look at the future prospects of air cooling in relation to the cooling of more and more powerful processors.

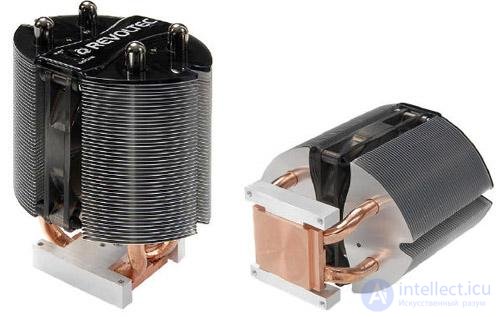

Figure 2. Revoltec Freeze Tower ().

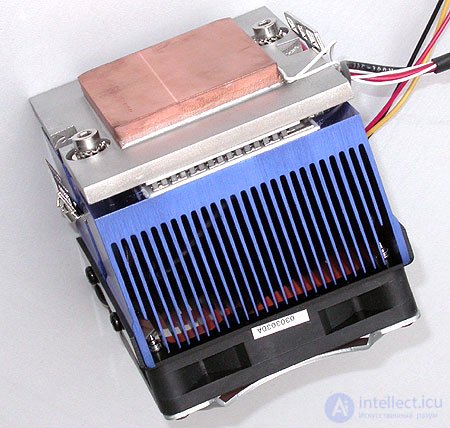

There is much to strive for and the creators of the motors, and the designers of the blades. And in terms of improving the efficiency of the main function and in terms of reducing noise. In the field of traditional coolers in general, there is still something to strive for. There are combinations of different materials in one radiator, when, say, the base is made of the same material, and the fins are from another, and the fans with increased power, and the piezoelectric cooling fins (Fig. 2).

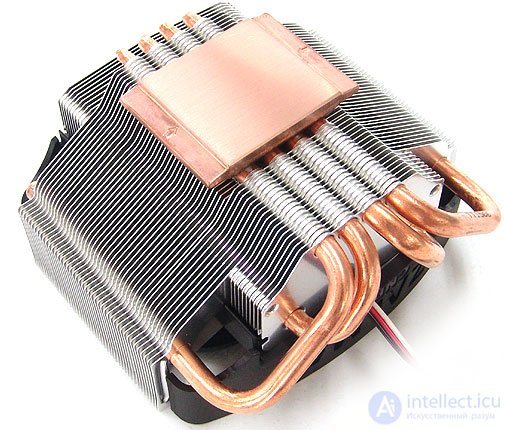

Figure 3. Scythe KATANA Cu

At present, much has changed in this area - a good half of the models have moved to the category of irrelevant, cooling systems with original designs and improved characteristics have appeared on the market.

The power consumption and, as a result, the heat emission of representatives of a large family with the Intel Core architecture turned out to be much lower than the most optimistic forecasts. Almost all modern AMD processors were originally distinguished by moderate power consumption, and now users are also offered more economical Energy Efficient models. Therefore, manufacturers of coolers today pay a lot of attention not only to the effectiveness of their solutions, but also to improving the appearance and noise characteristics of cooling systems, as well as ensuring maximum compatibility of products with various processor sockets. Some companies even return to proven design solutions, only slightly upgrading them (Fig. 3). With the release of the Core 2 Duo, the cooling efficiency requirements during normal operation have dropped significantly. However, to uncover the frequency potential, improved heat dissipation will be needed, and the emergence of quad-core processors will renew interest in alternative cooling systems.

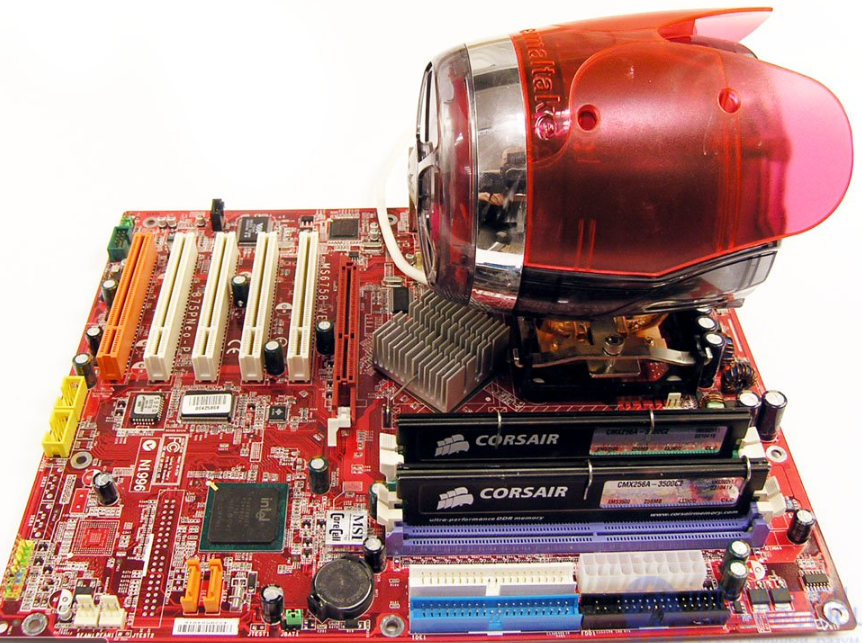

Figure 4. Zalman CNPS8000

Today, in the production of most cooling systems, heat pipes are massively used in the design, which allow reducing the total mass of the radiator while maintaining its high efficiency, improving heat transfer from the base of the radiator to the fins, and using relatively cheap aluminum instead of copper (Fig.4.5).

Figure 5. Thermaltake Beetle

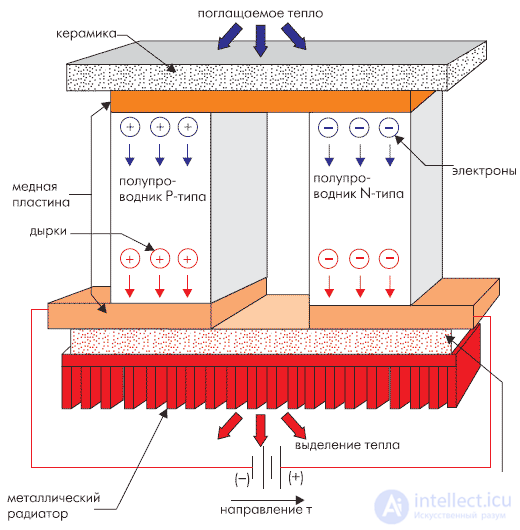

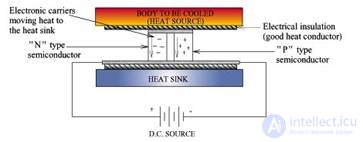

There is another interesting interface between the chip and the radiator, based on the effect discovered in the first half of the 19th century, after its discoverer, which was called the Peltier effect. The effect is that the voltage applied to two opposite material causes a temperature difference. Flowing into one, electrons pass into a higher energy state, absorbing heat, returning to another, they release this heat. A typical thermoelectric module, therefore, consists of two well-transmissive ceramic plates, which are its shell, and pairs of adjacent P and N doped semiconductor bismuth semiconductor materials located between them (Fig. 6).

Figure 6. Peltier element.

When voltage is applied, one of the sides is cooled, the other is heated. It is by no means a means of cooling, as people who are not well-versed in the subject often refer to Peltier elements. It is a heat pump that does not convert heat into cold, but simply, in fact, effectively transfers it from one end to the other. The amount of work done, of course, is completely dependent on the voltage and current, and in existing models on the market today, the difference between the cold and hot sides of an element can be a very impressive amount. Up to 65-70 degrees in the case of using one pair of thermoelectrics, and even more - if such pairs in one element overlap each other (Fig. 7).

Figure 7. Cooler with Peltier Thermoelectric Module - Thermaltake SubZero4

Yes, we can safely make the temperature of the side adjacent to the processor, say, 0 degrees Celsius. The whole question is what kind of energy costs it will cost us, and what will be the temperature of the hot side, which will have to be cooled by the usual methods. The Peltier element can somewhat ease the life of the chip, since, being a small area, it is able to divert much more heat directly from the chip than any radiator of much larger size, but it cannot reduce the amount of heat in the system chip radiator, by definition. This is just a heat pump.

So further with the removal of heat will have to fight either all the same classic cooler, or something somewhat more powerful. Powerful - read, having the best heat conductivity, than air. Yes, we are talking about liquid cooling in all its manifestations. Due to its higher thermal conductivity, the liquid better absorbs heat from its sources, and its forced cooling in the space provided for this may not be limited to bringing it to room temperature, whereas in the case of air we have to use what we give.

Figure 8. Liquid cooled system.

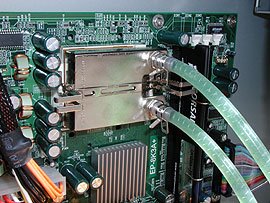

The classical scheme in this case is as follows: a hollow metal plate is in contact with the chip through which the coolant flows. Having absorbed heat from the walls of the plate, heated by a chip, it enters a special reservoir. From it, with the help of a pump, the heated liquid is transferred to a heat exchanger, where it takes off heat using air. The newly cooled liquid falls into the same plate that is in contact with the chip (Fig. 8.9).

Figure 9. Water cooling system Thermaltake Aquarius II.

These systems differ from hydrogenous ones only in that a thermal agent, freon, is used instead of water as a coolant. Accordingly, the circuit is completely and necessarily sealed, and the pump and the heat exchanger are distinguished by improved quality (Figure 10).

Figure 10. Asetek Vapochill evaporative cooling system

The result is a kind of minifridge on the processor. With a standard heat dissipation of 70 W, the temperature can be maintained around 5 ° C. Efficiency is higher, but the cost is at least several hundred dollars.

However, no one forbids using more complex cooling technologies in the heat exchanger - this is solely a question of the cost of the system. For example, you can consider such an option as pulsating heat pipes, also known as cyclic ones.

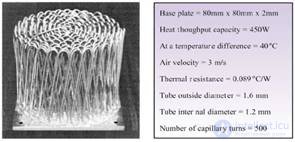

We take a thin tube and bend it so that it creates many U-shaped transitions. The tube is not completely filled with liquid, but so that there is free space. As a result of the fact that one side of this entire system is adjacent to the heat source, and the other side is cooled by the air flow, evaporation and precipitation of liquid begins inside, with the formation of steam bubbles and their transformation back into liquid as the pressure in the system constantly pulsates. These processes are the only driving force inside the system, moving the liquid from its warm end to the cold end, and back! That is, we simply cross out a number of unnecessary things in this case, such as a hydraulic pump (Fig. 11).

This technology has not been studied enough to bring it to mass use, but judging by the first experiments, its prospects are the most optimistic. This openwork "crown", installed on a base of 80x80x2 mm, is capable of passing through itself up to 450 W of heat with a temperature difference on its different sides of up to 40 degrees, being blown by an air flow at a speed of only 3 m/s.

Figure 11. Cyclic heat pipes.

We can also recall other interesting and possibly promising methods of heat removal. For example, the method of heat transfer by liquid inside a radiator plate is somewhat similar to the process just described, when it uses a capillary structure, through which the liquid transfers heat from the heated end of the plate to the cold one, and then returns back. As a result, the thermal resistance of the plate decreases compared to if it were made of pure metal, which improves heat transfer from one side to the other. This allows some video card manufacturers to make solutions with such radiators that do not require forced cooling by air flow.

Moreover, there are proposals to use this approach more, so to speak, integrated. That is, to make chips in which the capillary structure will be used not in the radiator, but in the body of the chip itself. It is clear that the idea has its own sound core - heat is removed directly from the heat sources, and the interface thermal resistance can be completely forgotten due to its actual absence. Although it is clear that it is simply pointless to seriously talk about any possibilities of using this proposal in modern processors, where every square millimeter counts. Here, even cryogenic cooling will be cheaper, considering how much the smallest particle of chip area costs today. This once again emphasizes that when we talk about cooling processors, the cost of solutions is as important as their efficiency. That is what the mass market is for.

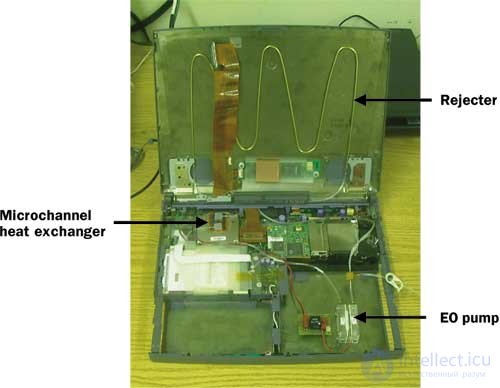

Or, for example, another similar option. But here, electric forces are added to thermodynamics. There is such an effect - electroosmosis, when an external electric field moves ions in a liquid, forcing its entire volume to move in the same direction. As a result, we have the opportunity to create a miniature hydraulic pump that does not have moving parts - an ideal option for using classic water-cooled systems in PCs. Scientists from Stanford have studied such systems in combination with radiators with an internal capillary structure, and have achieved very encouraging results, which make it possible to recommend such combinations, for example, for use in powerful laptops (Fig. 12).

Figure 12. Electroosmosis system in combination with radiators with an internal capillary structure.

As chips become more powerful and miniature, today's mass solutions based on cooling metal heatsinks with air flow will begin to recede further and further into the past, giving way to the above solutions or even their combinations. Fortunately, over the years that the current approach has been used, technology has made a significant leap, so that the possibility of their entry into the commercial market is already visible. The latest models of High-End graphics cards, which can be optionally purchased with a water cooling system and the availability of a wide range of systems for water cooling of the central processor on the market prove this once again.

However, there are cases when even this level of cooling is not enough. However, there are several more fundamental issues. For example, about the direction of development of all microelectronics, as such. Today, the power of the chips is increasing in all known ways - by reducing the size of transistors, increasing their number, and the voltage / size ratio of the transistor.

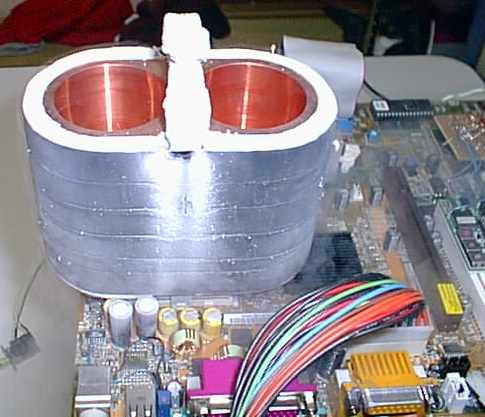

Meanwhile, several decades ago serious research was conducted on the effect of low temperatures on the operation of electronic circuits. The combination turned out to be ideal: the performance increased due to the reduction of the transistor switching time and the resistance of the intertransistor connections, while reliability increased due to the increase in service life and the reduction in the number of failures. Thus, there is an alternative option for increasing the performance of chips - it is enough to cool them to very low temperatures. By the way, this is what their manufacturers use when they need to show the potential of their brainchild - it is enough to use liquid nitrogen.

Figure 13. Liquid nitrogen cooling system

The most "hardcore", most inaccessible, most inconvenient and most effective approach today is "nitrogen cooling". Liquefied gas - nitrogen, having a temperature far below zero Celsius (Fig. 13) is poured into a container fixed on the crystal. Here, the question of effective supply of cold coolant does not arise, because it is either there (and has its own - 196 ° C), or it is not. Heat exchange is also not a problem for the same reason - the container on the crystal has virtually the same temperature - 196 ° C, while there is liquid nitrogen there.

And the removal of hot coolant is also not a problem, since everything happens by itself - nitrogen quickly and noisily evaporates. But this approach, with all its advantages, still has one insurmountable problem - the liquid nitrogen itself, which will need to be bought in huge quantities and regularly added to that horrible, frost- and fog-covered structure that was once your personal computer.

As the results of experiments show, on average, depending on the chip characteristics, we can talk about an increase of 1-3 percent in the performance of CMOS transistors for every 10 degrees Celsius decrease in temperature. This is quite a lot - by reducing the chip temperature, for example, from 60 degrees above zero to 40 degrees below zero, as Kryotech does quite successfully today, we will get a total decrease of 100 degrees, and this is already plus 10-30 percent to the performance, which today for central processors gives an increase of hundreds of megahertz.

However, it so happens today that the acceleration of chips by traditional methods is considered a cheaper and simpler option. Therefore, manufacturers prefer to invest billions of dollars in improving process technology, and more or less noticeable examples of using cryogenic cooling methods using compressors (a scheme like which air conditioning and a refrigerator work) are the same Kryotech with its Athlon-based systems, and IBM, with some of their servers.

Although it is worth a little more detail to touch on this method, especially since it is used in commercial PC. The method is perhaps the most “difficult” because it is potentially capable of cooling even to liquefaction gas temperatures, that is, much lower — 200 Celsius. It is based on the use of easily evaporating liquids and on the fact that gases (in this case, this is the most evaporated liquid), are cooled when expanding, whereas these same vapors compress when using a compressor. In the condenser, expanding, they give off heat (both from the chip and what was obtained during compression), condensing back into moisture, which again goes to the plate adjacent to the chip in order to evaporate once again.

However, as already mentioned, despite all the potential (and demonstrated) power of such an approach, it is not so often used. In some ways, this position is justified, because, nevertheless, water and chips are incompatible concepts, so any use of liquid cooling systems for PC manufacturers is quite troublesome. It is necessary to carefully monitor all issues related to tightness, the appearance of condensate, etc. Let's add here a rather large occupied volume in the PC case and a rather high cost, and we will understand why this cooling method has not yet received mass recognition. However, we will wait a few more years until the temperature of the chips rises to the point when new cooling methods are required.

The use of "open liquid".

It is possible that then these considerations will not play a special role, moreover, even more extreme technologies will be used, based on the use of an "open liquid", not driven into different tanks, but having direct contact with the chip.

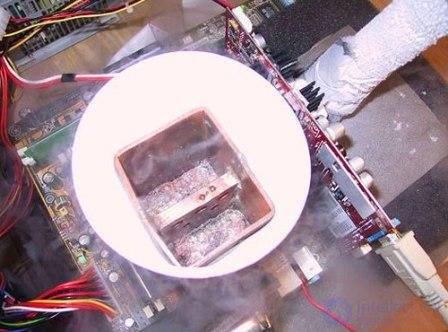

The first of these methods, which is also the most striking in its effectiveness, is the complete immersion of the inside of a computer in a cooling solution. In this case, we generally completely get rid of the thermal resistance of the plate adjacent to the chip, which contains water, and all other similar thermal interfaces. Direct contact - heat is immediately transferred to the cooling medium.

It seems to have just been said about the complete incompatibility of chips and water? Yes. But here the whole trick is that it means that there are unique compositions that have a liquid state of aggregation, but which are at the same time full dielectrics. So the chip can work safely, being immersed in such a solution - the absence of short circuits is guaranteed just as if there were air between the contacts. Today, the generally accepted option in this case is a whole class of fluorocarboxylic fluids, of which the proposed 3M brand "Fluorinet", which is also a whole set of products with different properties, is most known. Its thermal properties are worse than those of water, but due to the fact that direct contact with the chip is possible ...

IBM was actively working with such systems. Fluorocarbon compounds were used in cooling CRAY

-2. Naturally, we are not talking about simply removing heat into a liquid, otherwise, at the temperatures of the current chips, the module with it would quickly turn into a boiling pot. As in systems with indirect liquid cooling, there is also a cooling unit here, where the composition can transfer the heat absorbed by them from the chips.

There is one more, no less curious method of using liquids in the open form. It uses the well-known fact that the evaporation temperature of liquids decreases. Further, roughly speaking, it is clear - in this case, the chip radiator is a miniature pool, from where the liquid evaporates. Due to this, the bottom of the pool adjacent to the chip is cooled, and the steam is somehow collected and condensed back into the same liquid. In general, something resembles the above described cryogenic method. The method is very exotic, in commercial solutions today is not used.

Additional protection of the CPU from overheating can be provided by special software, so-called software coolers or cooler programs. The principle of operation of these tools is based on the introduction of temporary stop commands to the cycles of the processor for periods during which the computer processor is not loaded. A stopped processor consumes less power and consequently produces less heat. Similar functions have been introduced in operating systems such as Windows NT and Linux. These systems perform the so-called halt-cycle in low-priority tasks. When this happens, the processor core is temporarily stopped, but other systems continue their work.

For Windows, there are specially designed programs and drivers that perform the functions of temporary stopping the central processor. As an example, such popular and popular programs as Cpuldle, Rain, Waterfall Pro, etc. can be cited. Using programs of this type, it is possible to achieve high results of overclocking processors even with regular cooling tools and significantly more significant results with the use of additional tools.

It should be noted that the program Cpuldle not only provides the program cools the processors, but in some cases optimizes their work. Modern processors have some additional features that sometimes boost performance. If these functions are not involved, the program can activate these functions and thereby improve system performance.

Cpuldle can also control the temperature of the processor. If it exceeds a certain, user-defined value, Cpuldle can, for example, increase its priority for cooling the processor or even initiate the process of shutting down the computer. For this, it is necessary that the system supports monitoring of the processor parameters, in particular, temperature, and the monitoring program MotheBoard Monitor must be installed on the computer.

In general, the options, in fact - the sea. And the whole question often is not how effectively they will do their main job of cooling the chips, but how much it will cost. And more precisely - the ratio of these two factors. In addition, there are other nuances. For example, in the case of air cooling, we need to open all the radiant parts to the air as much as possible. But to reduce electromagnetic interference (whose level is very tightly limited in a variety of standards, and by definition should be kept under control at least for everything to work), on the contrary, it would be ideal to close these same radio-emitting parts into metal shielding packaging. You have to look for a balance. And so - in everything.

Besides, if not so long ago we could talk a maximum about cooling the CPU, then today: the north bridge of the chipset, the graphics processor, and sometimes already the hard drive. At today's spindle speeds that reach 15,000 revolutions per minute, no sophisticated technology can save us from heating, so High-End drives are heated more than noticeably. Here, the requirements of the form factor are high, as nowhere else, so that the manufacturers of hard drives have to sweat. Nevertheless, as has already been said, sets of two or three fans began to appear, intended to be placed in the front panel and blowing the hard drive. Hot air, therefore, is pushed into the body, which does not solve the problem of dealing with the temperature inside it. And here, so far no radical methods have been proposed. Except, perhaps, the second additional fan. So far this is more or less enough, but it is obvious that in the future there will also need the arrival of new technologies. What - so far it is quite difficult to imagine.

продолжение следует...

Часть 1 Electronic cooling systems

Comments

To leave a comment

Design and engineering of electronic equipment

Terms: Design and engineering of electronic equipment