Lecture

Troubleshooting electronic devices is a complex and multi-step process. Quickly, you can find only the simplest faults. Although these materials are written on the example of electronic devices, but there are materials that carry and are rather abstract in nature. I bring to your attention a cycle of materials: Strategy for troubleshooting. and Troubleshooting methods. As well as the reasons for the inoperability of electronic devices.

A few years ago, I wrote a note: "Methods for finding and repairing faults, as well as the causes of inoperability in CEA.". Recently got his hands to bring it into relative order. Then this article was conceived. The fact is that, having even the most perfect tool, you can not be able to use it. Accordingly, this note is about the correct, in my opinion, the use of tools for troubleshooting. Naturally, I do not pretend to build an exhaustive, flawless scheme by which one could find any malfunction and solve any problem. This text is only an attempt to summarize my experience.

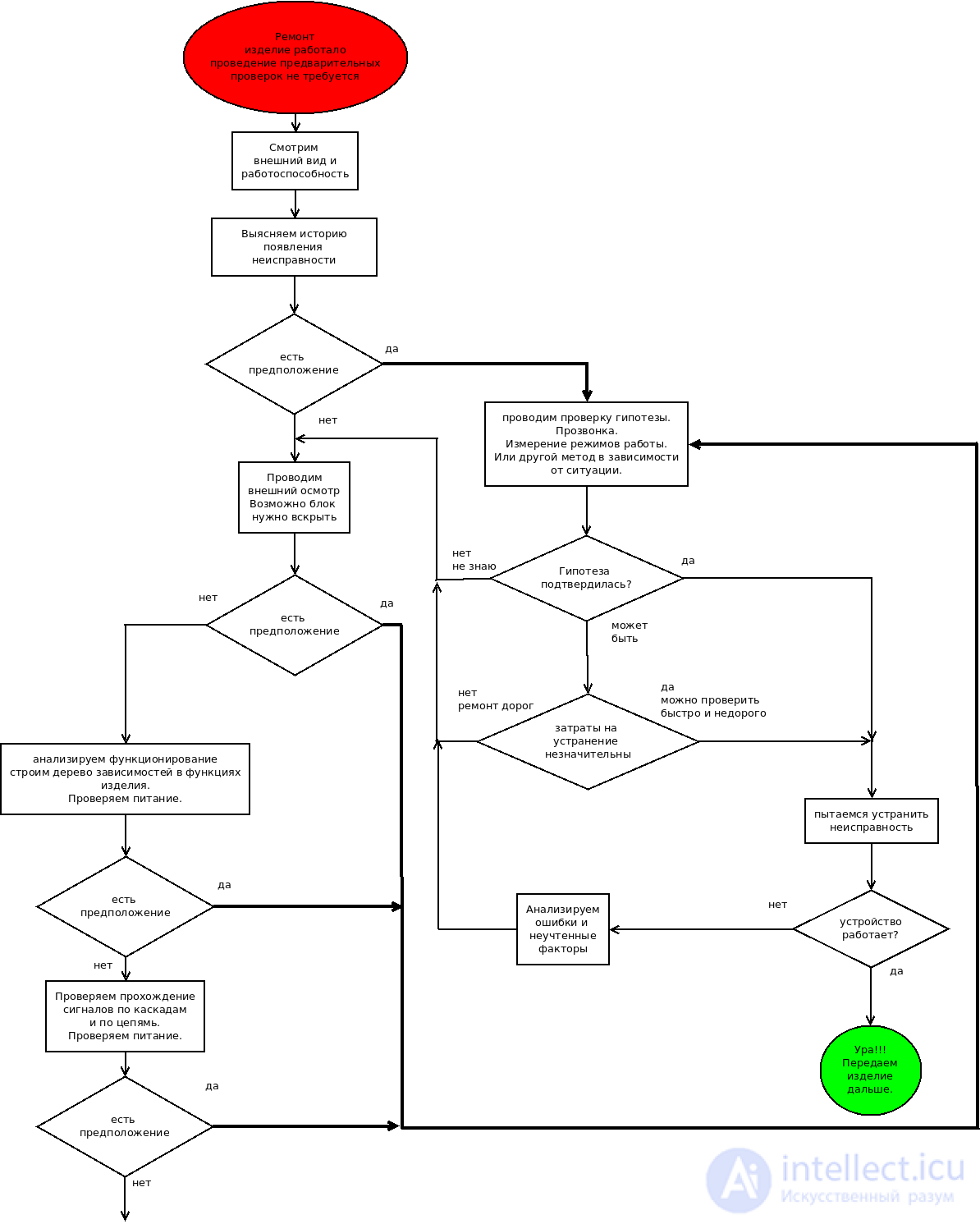

Procedure. The procedure always wants to be reduced to a simple and clear scheme. I first had the idea to express all this in a universal flowchart, but the search process is always too multivariate and requires attention to detail. Even a minimal, randomly obtained bit of information can push the solution of the problem. Also, the initial information is always of poor quality, and the choice of the factor on the basis of which one should begin to act is largely intuitive. Naturally, this does not mean that repair is identical to fortune-telling on the coffee grounds, or random sorting, but the random factor is always present. Of course, with a careful and consistent approach to the analysis, we will get a positive result. First of all, you need to remember that every action should be aimed at localizing the fault. AND, although in the early stages localization may not be accurate, but you still need to understand what you are striving for and what you expect from this or that dimension. First, you should always use quick methods, such as "visual inspection" and "finding out the history of the occurrence of a malfunction." Do not neglect these things. They are very effective. Actions during the repair of a used product and when a new product is launched are somewhat different. When we have a product out of service, we can assume that it worked, in other words, there are no errors in volumetric installation, there are no errors in installation on printed circuit boards, all elements of the correct denomination and type. At the same time, in the new product, before turning it on, we must check the printed wiring, check the correctness of the surround installation. And only then try to turn on the product (in more or less complex and mass products). Of course, it is impossible to create a universal procedure, but you can draw a scheme in general terms. The figure in general terms shows the scheme of actions: Explanations to the picture: Preliminary checks imply checks for compliance with the documentation, such as: correct installation, no closures, no pollution, and so on, depending on the production conditions. As you can see, the troubleshooting is cyclical, except for the simplest case. With a negative result on the next cycle, a deeper study of the product should be applied. In this case, a health check can be carried out depending on the situation by the most convenient method. After the stated problem has been stranded, the product should be tested in full.

Explanations to the picture: Preliminary checks imply checks for compliance with the documentation, such as: correct installation, no closures, no pollution, and so on, depending on the production conditions. As you can see, the troubleshooting is cyclical, except for the simplest case. With a negative result on the next cycle, a deeper study of the product should be applied. In this case, a health check can be carried out depending on the situation by the most convenient method. After the stated problem has been stranded, the product should be tested in full.

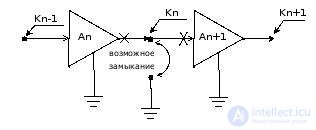

When we use one or another method, we pursue several goals: collecting information, testing a hypothesis of a malfunction, localizing a malfunction. And at each step of our actions we get new information, and test the hypothesis, and localize the fault. It should be understood that - the primary in the current step, and that - again. At the same time, one should not neglect secondary effects. For example, when the main purpose of an action is to test a hypothesis, then the information obtained during this test may serve to refine the hypothesis put forward or allow a new assumption to be put forward. For faster localization of the fault, apply the principle: "Divide and conquer". To do this, you must first gain control over the key points of the scheme. Knowledge of the main, the main will save you from having to go into unnecessary details. I will try to describe the general scheme of action on an example. There is a big system that does not work correctly. First, isolate a separate block in the system. We include the block outside the system and isolate a separate module in the block. Then we turn on the module and exit to the element. In this slim system, there is one problem. For example, the module itself works correctly, and errors begin in the block. This is a problem of non-compliance of the working conditions of the module (block, element - not important) in the system and on the test bench. There are always such differences! Do not deceive yourself. First of all, of course, they think about differences in electrical signals, differences in temperature, cooling. In practice, these differences are not always obvious. For example, in my practice there was an interesting case when vibration was a significant factor. And, the board did not have vibration-sensitive elements, the board was strong enough, etc. But the replaced triacs burned out time after time. The reason turned out to be in graphite dust, which huddled under the connectors in the power circuits and in vibration conditions created a short circuit, while at the stand everything worked fine. The isolation of key points is quite complex and requires a good knowledge of the principles of operation of the device and its structure. In the simplest cases, the device should be divided into star structures and successive structures. In star structures, they first investigate (if possible) the central node and, based on its work, make a conclusion about the operation of its and other nodes. If the study of the central node is difficult, then "first we chop off the branches, if we can not immediately cut down the trunk." That is, we first investigate the periphery, which is more laborious, but will provide information necessary for the study of the central node. In successive structures, you should make sure that the input signals are correct, the output signals are incorrect. Hence, the structure somewhere does not work. To fix the problem as quickly as possible, split the sequence of cascades in half and check the signals in the middle cascade. This way we will find out where the fault is at the beginning or at the end. Then divide the intended area in half again, and so on. But it happens that such an action strategy is inconvenient for technological reasons, or we have to analyze signals for each stage based on the signals in the previous stage.

Always first (or as soon as possible) you should check the supply circuit and the quality of the supply voltage. Keep in mind the goal and to the place to change it. It is necessary to understand what this or that action is directed to. On the collection of general information, on testing a hypothesis, on checking a particular block. At the same time, it is necessary to assess the result of the action in time and proceed to the next stage in time. When you collect information, you need to assess in time that the necessary information has already been collected and it is necessary to proceed to the analysis. No need to get hung up at any stage. This is not always easy and not always obvious.

We formulate the main strategic principles:

The problem is that you can not make a clear scheme of action. We are always forced to keep in mind all the principles and constantly look for what to use at the moment.

Here I plan to describe practical methods of troubleshooting in electronics, if possible, without reference to specific equipment. Under the causes of inoperability means the failure of the element, the mistakes of developers, installers, etc. The methods are interconnected with each other, and their complex application is almost always necessary. Sometimes the search is very closely related to the elimination. In the process of working on the text, it became clear that the methods are very interrelated and often have similar features. Perhaps it can be said that the methods overlap. However, it was decided not to combine similar methods into one, in order to highlight problems from different sides and more fully describe the process of troubleshooting.

1. The action should not harm the device under investigation. 2. The action should lead to the predicted result: - hypothesis about the health or malfunction of the unit, element, etc. - confirmation or refutation of the hypothesis put forward and, as a result, localization of the malfunction; 3. It is necessary to distinguish between a probable malfunction and a confirmed (detected malfunction), a hypothesis put forward and a confirmed hypothesis. 4. It is necessary to adequately assess the maintainability of the product. For example, boards with elements in a BGA package have a very low maintainability due to the impossibility or limited ability to apply basic diagnostic methods. 5. It is necessary to adequately assess the profitability and the need for repair. Often the repair is not profitable in terms of costs, but is necessary in terms of working out the technology,

The essence of the method: The history of the appearance of a malfunction can tell a lot about the localization of the malfunction, which module is the source of the system malfunction, and which modules have failed due to the initial malfunction, and the type of the malfunctioning element. Also, knowledge of the history of the appearance of a malfunction can greatly reduce the time of testing the device, improve the quality of repair, reliability of the corrected equipment. Figuring history allows to find out, is not the problem the result of external action, such as: climatic factors (temperature, humidity, dust, etc.), Mechanical stress, pollution by various substances, and so on. The possibilities of the method: This method allows very quickly to hypothesize a fault localization . Advantages of the method:

Disadvantages of the method:

Application of the method:

The essence of the method: External examination is often neglected, but external examination allows localizing about 50% of faults, especially in small-scale production. External inspection in terms of production and repair has its own specifics. Method features:

Advantages of the method:

Disadvantages of the method:

Application of the method:

Naturally, in all cases, you should pay attention to any mechanical damage to the housing, electronic components, circuit boards, conductors, screens, etc., etc.

The essence of the method: The essence of the method is that with an ohmmeter, in one form or another, the presence of the necessary connections and the absence of unnecessary connections (closures) are checked. Method features:

Advantages of the method:

Application of the method:

The essence of the method. When using this method, the product is included in the working conditions or in conditions simulating workers. And check the characteristics, comparing them with the required characteristics of a working product or theoretically calculated. It is also possible to take characteristics of a separate unit, module, element in the product. Method features:

Advantages of the method:

Disadvantages of the method:

Application of the method: For example:

The essence of the method: With the help of measuring equipment (oscilloscope, tester, spectrum analyzer, etc.) observe the correctness of the propagation of signals through the stages and circuits of the device. To do this, carry out measurements of the characteristics of the signals at the control points. Method features:

Advantages of the method:

Disadvantages of the method:

Application of the method:

Fig.1 Temporary modification of the device to eliminate the ambiguity of finding a fault. Crosses indicate a temporary connection break.

The essence of the method: It consists in comparing the various characteristics of a known-good product and a faulty one. The differences in appearance, electrical signals, electrical resistance are judged on the localization of the fault. Method features:

Advantages of the method:

Disadvantages of the method:

Application of the method: Comparison with the serviceable unit is a very effective method, because not all product characteristics and signals are not documented in all circuit nodes. It is necessary to begin a comparison with a comparison of the appearance, arrangement of elements and configuration of the conductors on the board, the difference in the installation indicates that the product design has been changed and, quite likely, an error has been made. Then compare the various electrical characteristics. To compare the electrical characteristics, the signals are viewed at various points in the circuit, the operation of the device in different conditions, depending on the nature of the fault. It is sufficient to effectively measure the electrical resistance between different points (peripheral scanning method).

The essence of the method: The behavior of a serviceable and faulty device is simulated and, based on modeling, a hypothesis about a possible malfunction is put forward, and then the hypothesis is checked by measurements. The method is used in combination with other methods to improve their effectiveness. Method features:

Advantages of the method:

Disadvantages of the method:

Application of the method: When eliminating a periodically occurring fault, it is necessary to apply a simulation to find out if the element being replaced could have provoked the fault. For modeling it is necessary to present the principles of operation of the equipment and sometimes even know the subtleties of work.

The essence of the method: To pre-localize the fault is very effective to break the device into functional blocks. It should be borne in mind that often the design division into blocks is not effective from the point of view of diagnostics, since one building block can contain several functional blocks or one functional block can be constructively implemented as several modules. On the other hand, the structural unit is much easier to replace, which allows you to determine which structural unit the fault is in. Method features:

Advantages of the method:

Disadvantages of the method:

Application of the method: Two options are possible:

The essence of the method: To eliminate mutual influence and to eliminate ambiguity in the measurements, sometimes it is necessary to change the product design: break connections, connect additional connections, unsolder or solder elements. Method features:

Advantages of the method:

Disadvantages of the method:

Application of the method: Partial disconnection of chains is used in the following cases:

It is necessary to disconnect the protection circuits and negative feedback circuits with special care, since turning them off may cause significant damage to the product. Disconnection of the feedback circuits can lead to a complete disruption of the operation mode of the cascades and, as a result, not to give the desired result. Disconnection of the POS circuit in the generators naturally leads to the breakdown of generation, but it can allow to take the characteristics of the cascades.

The essence of the method: In fact, the method is a combination of methods: Breaking up into functional blocks and Removing external performance. Upon detection of faults, the “suspect” block is checked outside the system, which allows either to narrow the search range if the block is healthy or to localize the fault within the block if the block is faulty. Method features:

Advantages of the method:

Disadvantages of the method:

Application of the method: When applying this method, it is necessary to monitor the correctness of the conditions created and the tests applied. Blocks can be poorly coordinated with each other at the design stage.

The essence of the method: The functional unit is pre-checked outside the system, on a specially made stand (workplace). When repairing this method makes sense if the unit does not require too many input signals or, in other words, it is not too difficult to simulate the system. For example, this method makes sense to apply when repairing power supplies. Method features:

Advantages of the method:

Disadvantages of the method:

Application of the method: It is widely used for the prevention of system malfunctions in the production of new products.

The essence of the method: The suspected unit / component is replaced with a known-good one, and the functioning of the system is checked. The results of the test are judged on the correctness of the hypothesis regarding the malfunction. Method features:

Advantages of the method:

Disadvantages of the method:

Application of the method: Several cases are possible: when the behavior of the system has not changed, this means that the hypothesis is incorrect; when all faults in the system are eliminated, it means. the fault is indeed localized in the replaced block; when a part of the defects disappeared, this may mean that only the secondary malfunction has been eliminated and the serviceable unit will again burn out due to the primary defect of the system. In this case, perhaps the best solution would be to re-install the replaced unit (if possible and appropriate) and continue troubleshooting with that. to eliminate exactly the root cause. For example, a power supply failure may result in unsatisfactory operation of several units, one of which fails due to overvoltage.

The essence of the method: Compare the values of currents and voltages in the circuit with supposedly correct ones. They can be found in the documentation, calculated when modeling, measured in the study of a good unit. On this basis, make a conclusion about the health of the element. Method features:

Advantages of the method:

Disadvantages of the method:

Application of the method:

продолжение следует...

Часть 1 Troubleshooting. Methods of troubleshooting As well as the reasons for the inoperability of electronic devices.

Скажите пожалуйста как проверить что диод рабочий или не рабочий?

нужно наверно сначала определить какой это тип диода? а потом проверять соответствующие параметры.

типа если варикап то емкость и тд?

Подробнее читайте тут как проверить любой диод

https://intellect.icu/5-neispravnosti-aktivnykh-i-passivnykh-elektroradioelementov-rezistorov-diodov-tranzistorov-kondensatorov-i-mikroskhem-3304

Comments

To leave a comment

Diagnostics, maintenance and repair of electronic and radio equipment

Terms: Diagnostics, maintenance and repair of electronic and radio equipment