Lecture

Objective: to learn on the basis of structural and functional schemes to develop

functional model used to develop a troubleshooting algorithm.

The main elements of the monitoring and diagnostic system for household electronic equipment are:

the object of diagnosis (the source of diagnostic information) - the diagnostic

May household REA;

diagnostic equipment (means of technical diagnosing) - equipment

development of test actions and their supply to the object being diagnosed and the equipment

storage, processing and analysis of diagnostic information;

means of transmitting diagnostic information;

consumers of diagnostic results.

The combination of these elements forms a system for monitoring and diagnostics of household

CEA, designed to determine its current technical condition and to search for

with a given depth

The monitoring and diagnostic systems for household electronic equipment can be different in their purpose.

structure, installation site, composition, design, circuit solutions. They are

are fostered according to a number of attributes that determine their purpose, the composition of technical means, the structure

tour, solvable problems.

The process of diagnosing is a multiple flow at the object of diagnosis.

certain effects and repeated measurement and analysis of the responses (reactions) of the object

on these impacts. Depending on the method of submission to the object of diagnostics

effects distinguish test and functional diagnostics systems, generalized

whose functional diagrams are shown in fig. 8.1.

Functional diagnostic systems are used as a test action.

vii work signals. These effects correspond to the working algorithms of functioning of the

diagnostics and can not be chosen arbitrarily. Functional Diagnostic Systems

As a rule, they are used during the operation of REA, for example, the system of

control. They allow you to replace failed nodes in the process of work, go to

other modes of operation, the day of which the malfunction occurred is insignificant, i.e. build adap-

tive systems.

However, the limited range of working influences does not always allow optimally solving

diagnostic tasks. If necessary, increase the depth of troubleshooting enter sensors

states of smaller nodes. Functional diagnostic systems are fundamentally

allow you to detect the failure of any element, as in the practical schemes of electronic equipment each element

performs a specific function.

Test diagnostics systems use test exposures that are expressed

battled by diagnostic devices. Therefore, both the composition and the sequence of submission

these effects on the diagnosed CEA are determined from the conditions of effective control and

diagnostics. At the same time to obtain effects and responses can be used not

only the main inputs and outputs of the equipment, but also internal nodes and branches. This contributes 69

obtaining a greater depth of search for defects with less time and equipment. Tes

This diagnosis can be performed not only during troubleshooting and setup,

but also with the normal functioning of the equipment. In order for test impacts not

influenced the normal operation of the diagnosed equipment, they are served, for example, during

sneeze pauses this part of the equipment.

Monitoring and diagnosing household CEA involves some of its idealization,

which highlights some essential characteristics (for monitoring and diagnostics) and

secondary ones are discarded, i.e. real household CEA is replaced by a model.

When troubleshooting household REA is usually presented in the form of functional

model or functional logic circuit. The functional model is different from the structural

schemes by the choice of primary functional elements. Under the functional element is understood

part of the object being diagnosed (node, cascade, group of cascades, separate radio component),

which can only be in one of two states: good or bad. When

the structure of the structural scheme proceed from the laws of work processes in the diagnosed

equipment, while constructing a functional model based on a given accuracy

localization of faults taking into account the design features of the equipment.

As practice shows, the diagnosis must be carried out before the failed radio component

nta. At the same time, it is most rational to conduct troubleshooting

levels: block - module - cascade - radio component. In accordance with this build several

functional models: for a device as a whole with a depth of troubleshooting up to the unit or

module for each block or module with a depth of search to a cascade or a separate radio component

nta.

The initial data for the construction of a functional model are:

block diagram of the object of monitoring and diagnostics; schematic diagram of the object

control and diagnostics;

description of the processes occurring in the object of diagnosis;

set depth of troubleshooting.

When building functional models, one should be guided by the following

forks:

in each functional element, the values must be known (nominal, permissible

k) input and output parameters, their functional dependence and method of control;

if at least one of the input signals exceeds the permissible limits,

an input signal that also goes beyond acceptable limits;

a functional element of the model of the object of diagnosis is considered to be faulty if

for all input signals lying within acceptable limits, a signal appears on its output

cash, the values of which are outside the allowable limits;

values of external input signals are always within tolerances;

if the output signal of the i-th functional element is input for the j-th function

element, then the values of these signals are the same;

lines of communication between functional elements are absolutely reliable;

any primary functional element of the model can have only one day off

signal with an arbitrary finite number of input signals.70

The functional model (fig. 8.2) is executed in the form of a graphic scheme, on which each

Each functional element is indicated by a rectangle with some input

arrows (input signals) and one output arrow (output signal). Output any

the functional element can be connected to any number of inputs, while the input of any

element can be connected with only one output.

Inputs that are not connected to any output are called external. They transmit

external effects on the object being diagnosed. External influences are denoted by xij, where i -

the number of the functional element, and j - the input number of this element. Functional outputs

elements are denoted by zi, where i is the number of the functional element.

After building a functional model, a set of possible states is determined.

object of diagnosis. Their total number when it is divided into N functional elements

with two alternative outcomes for each functional element is 2

N - 1. However, in

highly reliable devices to which household REA belongs, the simultaneous appearance

two independent failures are unlikely.

Table 8.1

Si zi

z1 z2 z3 z4 z5 z6 z7 z8 z9

S0 1 1 1 1 1 1 1 1 1

S1 0 0 1 0 0 1 0 0 0

S2 1 0 1 0 0 1 0 0 0

S3 1 0 0 0 0 1 0 0 0

S4 1 1 1 0 1 1 0 0 0

S5 1 1 1 0 0 1 0 0 0

S6 1 1 1 0 0 0 0 0 0

S7 1 1 1 1 1 1 0 0 0

S8 1 1 1 1 1 1 1 0 0

S9 1 1 1 1 1 1 1 1 0

Then the number of possible states of the diagnosed household CEA can be defined as

the number of combinations of N elements one by one:

CN

one

= N. (8.1)

The number of different states of the diagnosed equipment taking into account failures simultaneously

one functional element is reduced to a state table or a fault matrix. By-

the last one is a table in which the number of rows is equal to the number of functional elements-71

model, and the number of columns - the number of control points (output elements). The matrix is non-

correctness for the functional model of the TV soundtrack channel

UPIMCT presented in Fig. 8.2, is given in table. 8.1.

The fault matrix is filled based on a logical analysis of the functional

models of the equipment being diagnosed, provided that all the parameters at the test points on the

The moves of the functional elements are controlled. It is assumed that if the diagnostic

If the equipment is in the Si state, then only the i-th functional element is faulty.

This event corresponds to an invalid value of the output parameter zi and then to the intersection

In the case of a Si line and a zi column, the character 0 is written.

If in this case any other j-th functional element also has an unacceptable value.

zj, then the symbol 0 (not normal) is also written at the intersection of Si row and zj-column. If you know

If the parameter is in the tolerance e (normal), then the symbol 1 is written at the intersection.

The resulting fault matrix is used when developing a search program for

correctness.

Practical task:

1. Based on the analysis of work and structural schemes to develop a functional model

bringing it to mind in the picture.

2. To do this, select the input signals and mark them with X (block number). (Input number).

Note

3. Mark the output signals with arrows with the corresponding number (even if

optical or sound example)

one

2

3

five

four

6

eight

7

ten

9

Z1

Z3

Z2

Z6

Z4 Z7

Output

Z10

Z9

Z5 Z8

X3.1

Sign 72

Figure 2 - Functional models of devices

4. In drawing up diagrams there are cases when different electric

skysky signals (for example from the transistor cascade). This is contrary to the rules, then

ment mentally decompose into several components with separate outputs.

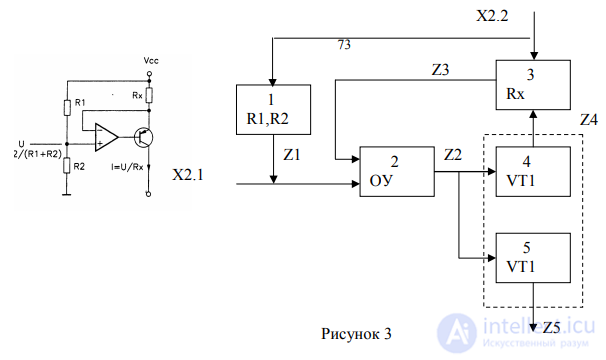

Example: A current generator circuit is controlled by a voltage U that converts it to the strength of a current on

transistor collector Figure 3. The output transistor forms two separate output

signal with different values of electrical parameters (this feature allows

you can say or not draw signals with the union). The input circuit signal is

on the non-inverting input of the op-amp and is summed with the divider signal at R1 and R2. Resistor Rx is

It is a limiting sensor. Direct output is taken from the collector and inverse

output from the emitter to the inverting input.

Note:

power supply circuits on FM are not represented as input signals

the numbering of the input signals contains the block number (first digit) to which the

Dinena If the signal is sent to several blocks at once, the first digit is missing.

Block 3 has no direct output, however, its condition will affect the signal

given to the input of the shelter

the transistor (single element) is divided into two components to comply with the rules of the FM.

Inside the rectangles it is possible to designate the reference designation of the elements of the

elements of the element (for convenience)

Functional model is compiled separately for each device operation mode.

(eg reception or transmission). In such cases, the switching elements are left

in the model at the discretion of the developer, for example, depending on the probability of

kaza switching element. However, he has only one way out (the second and the rest are not

portray for this mode).

Of particular complexity are microprocessor and microcontroller devices.

va. In them the same conclusions can be both input and output. In such cases, the

put the model depending on the mode of operation. Thus, there are as many of them as

Mov work. Another difficulty is the type of IC output and bus lines. Their following

do not represent one line, but for physical control you will need multichannel

instruments (for example, analyzers) 73

Figure 3

Comments

To leave a comment

Diagnostics, maintenance and repair of electronic and radio equipment

Terms: Diagnostics, maintenance and repair of electronic and radio equipment