Lecture

In terms of price, inkjet printers occupy an intermediate position between matrix and laser printers, they outperform matrix printers in print quality, but (for now!) Are a little inferior to laser printers.

Modern inkjet printers display text and graphics of high quality and are more than twice cheaper than laser (often around $ 100). In addition, they are smaller, not so noisy and consume less electricity than their laser counterparts. Studies by International Data Corporation show that this is one of the reasons why inkjet printer sales are growing faster than printing devices of all other types.

However, choosing an inkjet printer instead of a laser entails the need to make certain compromises: you will most likely have to sacrifice speed, and if you print more than a few dozen sheets per week, it is expensive because of the high cost of consumables (ink-cartridge).

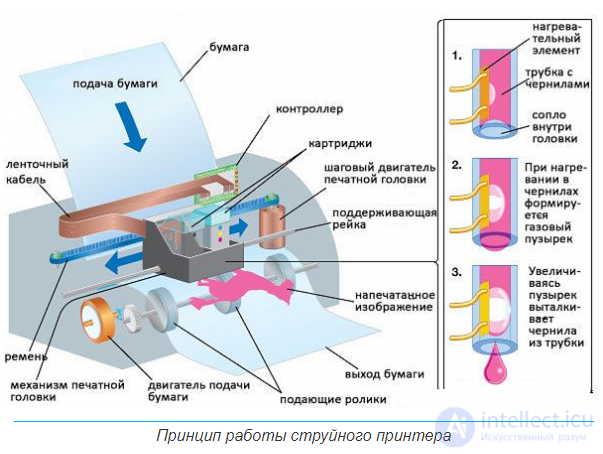

Like laser printing, the inkjet method is “shock-free”. The physical principle of the technology that provides inkjet printing is similar to the principle of operation of a jet engine and is based on the shooting of a drop of liquid from a special nozzle. A printhead containing ink has a group of tiny nozzles, each diameter thinner than a human hair. Behind each nozzle on the miniature resistor is a micro-reservoir with ink. When a resistor is heated by an electric current passing through it, the ink surrounding it boils, forming a small vapor bubble. This expanding bubble pushes the smallest ink droplets out of the nozzle onto paper, flying at a speed of about 700 km / h. After the drop is pushed onto the paper, the vapor bubble is compressed, and the resistor at this time waits for the next heating under the action of another current pulse. Such a cycle takes a fraction of a second, allowing the printer to print quickly and silently (since there are no mechanical impacts on the paper), pushing out droplets of 4 picoliter (in the most “advanced” models).

Significant progress in the inkjet printer market has recently occurred largely due to the efforts of the former undisputed leader in the dot-matrix printer sector, Epson. High quality at a low price has become a reality.

With an increase in the resolution and speed of printing, it turned out that the pursuit of improving these characteristics would not in itself provide a significant gain if it did not improve the image carrier, that is, paper. Any “tricky” technology will be powerless if you put simple office paper in the printer tray.

The surface of ordinary paper has a fibrous structure, due to the technology of its production. As a result, tiny, strictly calculated by the size of the drop begins to spread on the surface in an unpredictable way. One solution to this problem is the use of pigment inks, which are a suspension of dispersed particles in a colorless liquid carrier, since solid particles cannot penetrate into the inner layers and spread over the fibers of the paper.

Pigment-based inks produce bright and saturated colors, but they also have certain disadvantages, in particular, low resistance to external influences.

The technology of inkjet printing is such that the best result can be achieved only when using special paper. Photos on plain paper look faded and less clear. Unlike conventional paper with a special coating and the so-called photo paper have several special layers. Prints on it are almost indistinguishable from photographs obtained when printing with the use of chemical photoprocess.

Simple budget inkjet paper typically has a density of 90–105 g / m2, a relatively small thickness and excellent whiteness. Due to the special treatment of the front or both sides of this paper is more resistant to the vagaries of ink and prevents them from spreading and penetrating deep into the sheet.

Attention is paid to such important aspects as the rate of drying of ink and their resistance to sunlight and gases contained in the air (in particular, ozone).

refill cartridges - is the game worth the candle?

The main disadvantage of inkjet printers is the large overhead, the lion's share of which is the cost of new cartridges. And the most annoying thing is that every time you have to throw out almost a new device, which most often retains its full functionality, but has lost ink (moreover, it is not always completely spent).

Is it possible to save?

After all, for this "only" you need to learn how to refill cartridges. The answer of most manufacturers to such a proposal is "NO!" (this can be seen by opening the instructions). The main argument - the use of refilled cartridge increases the risk of the printer or its individual parts failing. If the service team finds out that the refilled cartridges are used, the owner will lose the warranty and hope for free repair. Many still decide on self-fueling, but the result of such an attempt to save may be different and quite ambiguous, depending on the brand of printer, the specific type of cartridges and ink used.

For example, in most Hewlett – Packard printers, the cartridge is combined with the print head in one case and they are replaced at the same time. This design increases the likelihood of refueling success and reduces the risk of printer failure - pouring a new batch of ink does not have to worry about the print head (following the instructions, you still have to throw it out with the cartridge!). With a known skill, you can successfully refill HP cartridges 5-10 times with a fairly stable result. The situation is completely different with Seiko Epson printers. The print head in them is made non-removable (at least, maintenance does not require it), only the cartridges are replaced, which are actually ink tanks. Firm CATEGORICALLY does not recommend refilling cartridges and in this matter it is impossible to disagree. The cost of such savings is often very high - poor quality inks clog the nozzles of a precision printhead and it is not always possible to “reanimate” it even at a service center. There is a great risk that the printhead will dry out during the time it is without a cartridge. If necessity forces to save, it is less risky to use cheaper third-party cartridges (for example, the same Print – Rite). At the same time, despite a number of successful experiments, we recommend that owners of Epson printers refrain from refilling and replacing the recommended cartridges with alternative ones.

The optimal (and most importantly - standard), dose adjustment scheme from our point of view is provided by many Canon printers (in particular, BJC – 50, BJC – 2000, BJC – 6000), which provide for the replacement of not only the cartridge combined with the print head, but also individual ink tanks inserted into the cartridge. With such a replacement, the most complete development of the resource is provided not only for the print head, but also for each reservoir (especially important for a color cartridge). The savings are also significant - for example, the ink tank for a BJC-50 monochrome cartridge costs 5-6 times less than the cartridge itself.

These examples are quite enough to understand the following - refilling cartridges is justified if the risk is minimized (refueling is provided by the manufacturer) or small (due to the design features). In this case, skillful refueling actions can really save a significant amount to the owner without any complication.

If refueling can most likely lead to the failure of an expensive printer unit (printhead, for example), such a risk is unjustified and other ways out of the situation should be sought.

Comments

To leave a comment

History of computer technology and IT technology

Terms: History of computer technology and IT technology