Lecture

Lecture questions:

1. Types of scales

2. Preferred numbers

and their meaning

3. The ratio between

qualimetric scales

4. Features of measurement

in qualimetry

1. Types of scales

Any measurement or quantification of something

or carried out using the appropriate scale.

The scale is an ordered series of marks corresponding to

the ratio of the successive values of the measured

lichin.

In qualimetry, a measurement scale is a means of adequately

cotton comparison and determination of numerical values from

individual properties and qualities of various objects. Almost use-

There are five types of qualimetric scales:

1) the scale of names;

2) the scale of the order;

3) scale of intervals;

4) scale of relationships;

5) the scale of absolute values.

1. Scale names. In cases where several

unknown sizes must be compared with one and

divide, which of them are equal to the size chosen for the base compared to

and which are not, then use the so-called scale

naming. On the scale of names classify sizes

on the basis of equivalence, identity, equality. Measurement

is to determine the sameness (equality) or different

of any size (inequality) of a size from a pre-determined

value.

Mathematical expression of the essence of measurement on a scale

titles can be written as:

Qi = or <> or ≠ Q j ,

where Q i is the size with which it is compared (base size);

Qj - j-th of compared sizes (j = 1, 2, 3, ... n);

n is the number of compared sizes.

When comparing and measuring sizes according to the scale of

The following conclusions can be drawn: fit - not fit;

fit - not fit; corresponds - does not correspond, etc.

Thus, for example, perform the calibration of

lei machines and other products at the enterprises-manufacturers

products, at the entrance control, as well as in some other cases.

2. Scale order. Order scale is consistent

a series of values giving a systematic view of

the simplest ratios of sizes of compared sizes

properties, attributes or qualities in the whole evaluated objects.

By pairwise comparison of all measured dimensions

establish which size is larger or smaller than another

better or worse than the other.

The established ratios of sizes are ranked in

a row of increase or decrease (decrease) of their values. Half

The ranked value resulting from the ranking is the scale

order of increasing or decreasing sequence.

Criteria for evaluation:

"The same or not"

"More or

less, which is better and which is worse.

Mathematical expression of the relations in pairs

available sizes are Q i = or ≠ or <> Q j

An example of the construction of scales of order may be.

Suppose there are five unknown sizes: Q 1, Q 2,

Q3, Q4, Q5. When pairwise matching is determined that:

1) Q 1 < Q 2 < Q 3 < Q 4 < Q 5 - the scale of increasing order;

2) Q 5> Q 4> Q 3> Q 2> Q 1 is a scale of decreasing order.

The ordinal number of the location Q in the order of

called rank

In order to increase the reliability and objectivity of measurements

rhenium ranking method is often introduced into the order scale

graded reference points, with the help of which

determined by the rank or also the dimensionless score measured

quantities. This scale is called the reference scale of order.

(tab. 1).

Table 1

Examples of reference scales of order and their measurements

The lack of measurements on scales of order can be considered

that the results obtained in the form of a ranked series are

less informative. In particular, with this measurement there is no

can determine how much more than one size

beyond the other, better or worse than the other. However advantage

measurements using order scales is that

with their help, instrumentally not measurable quantities yet

can be quantified (measured). Scale analysis

ka allows for some logical conclusions.

For example, if it is known that Q 1> Q 2, a Q 2> Q 3, then Q 1> Q 3.

3. Scale spacing. In many cases there is no possibility

measure the sizes themselves observable sizes but maybe

(or there is a need) to measure only the differences

between knowable size comparisons. In this case,

uses the so-called scale of intervals.

Differences are recorded on the measuring scale of intervals

comparable sizes. Mathematical Comparison

between two homogeneous sizes by their difference has

type: Δ Q i , j = Q i - Q j .

On the scale of intervals, determine such ratios of

measures like: equals (=), not equal (≠), greater than (>), less than (<), sum

(+) difference (-).

Examples of interval scales with one reference point are

There are calendar of calendar. In the christian calendar for

the zero point of reference is the year of birth of Christ ("9T

Christianity ”).

The classic example of measurements on the scale of intervals

with two reference points is to measure temperatures by

Celsius scale. Here, the reference dimensions are taken as

Freezing (melting ice) and boiling clean water. IN-

the interval between these temperatures is divided into 100 equal parts

tey One part, taken as a unit of temperature,

was called a degree. The Celsius scale is unlimited

travels outside the temperature range of 0 100 ° C, provided that

Any temperatures are measured by units equal to

1/100 part of the temperature range from freezing to boiling

water.

4. Scale of relations. In order to determine not only

by how much, but how many times one size is larger or smaller

other, or quantify the size of the size in official

units of measurement, it is necessary to use

be called a scale of relationships.

The relationship scale is the measuring scale on which

the numerical value of q i is counted. like a math

ratio of the measured size Q i . to another famous

size taken as a unit of measurement [ Q ].

In qualimetry it is considered that “any measurement on a scale

relationship involves comparing an unknown size with

the expression of the first through the second in a multiple or long

Mr. respect. " Mathematical record of measurement on a scale

relationship is:

Qi

qi = -----

[ Q ]

where i = 1, 2, 3, n is the number of the size being measured.

The scale of relations is a scale of intervals in which the

the zero element is divided - the origin, as well as the size (mass

headquarters) units of measurement [ Q ].

According to the scale of relations, such values of

matching sizes, like: equal (=), not equal (≠), greater than (>), less

(<), sum (+), size difference (-), multiplication (x), division (÷).

The scale of relationships is most appropriate for measurement.

most quality indicators, especially for such numerical

characteristics, as the geometric dimensions of objects, their

density, force, voltage, oscillation frequency and other.

5. Scale of absolute values. In many cases,

I measure the value of something. For example, directly

counted the number of defects in the product, the number of units

produced products how many students are present at

lectures, number of years lived, etc. etc. With such measurements

Absolute quantities are marked on the measuring scale.

actual values of the measured. Such a scale of absolute values

it has the same properties as the relationship scale,

with the only difference that the values indicated on this scale,

have absolute, not relative values.

2. Preferred numbers and their meaning

Usage based measuring scales

series of preferred numbers, usually metric

scales of intervals or absolute values, calculated,

for example, tolerance units of measured linear dimensions

or qualifications.

Preferred are the numbers most often used.

used in engineering, technology, science and other fields

activities of people. Preferred numbers are co

fight a certain set of interrelated numbers (a series of numbers),

which possess a systematizing property that allows

use them when choosing, assigning and measuring dimensions

various sizes. Most often, mathematical expressions are due

changing states have the form of a simple arithmetic (

neural) or geometric (non-linear) progression.

Since the decimal number counting system is accepted everywhere,

beginning with a unit, then the most convenient are geometric

cue progression including number 1 and having

multiple 10. International Organization for Standardization (ISO)

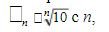

established (Recommendation P ISO 497) four major decade

number of preferred numbers with such denominators

In certain justified cases it is allowed to use

higher order series.

It should be noted that the established ISO series

significant numbers are based not only on the decimal system

accounts, but also on the principle of optimal ratios, which is

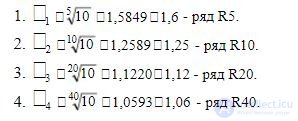

Alized, for example, in the "golden section". Under the "golden section

they understand the rectangle with sides a and b , which are correspondingly

rush among themselves as:

Based on the rule of the “golden section” in the 19th century, French

sky mechanical engineer Charles Renard proposed to unify

cable diameters (thickness) for balloons and sailing fleet

according to the law of geometric progression. Only many years later,

in the middle of the XX century, in order to ensure unity in the application

geometric progression for rationing geometric

parameters of technical products and their control of the accuracy of

The position of S. Renard was adopted and implemented through the requirements of

national (state) and international standards

Commodity products.

The series of preferred numbers are used to set

of the unified sizes of drills, cutters, reamers, countersinks

ditch and other tools, as well as sizes and tolerances

(deviations) of machine parts, products in general, technical

rammeters (properties) of products, percentage of defects in batches

products, voltages of electric current, but

minal values of the electromagnetic wavelengths of radio broadcasting

body ranges, etc.

Therefore, it is not by chance that the numbers of the nominal values of radio

broadcasting bands and carrying capacity of railway

P tanks have similar values, such as:

→ 80 m, 63 m, 49 m, 41 m, 31 m, 25 m, 19 m, 16 m, 12 m,

10 m;

P 80 t, 63 t, 50 t, 40 t, 32 t, 25 t, 20 t, 16 t, 12 t, 10 t.

Preferred numbers of geometric progressions are

are used, in particular, in qualimetry to establish great

the rank of the weight (significance) coefficients of individual indicators

quality lei, with the graduation of measures, with the division of the range

at intervals (formation of measurement scales), etc.

It is known that the nominal linear dimensions (diameters,

lengths, depths, distances between axes, etc.) of products, their parts

individual parts and connections as required

standards are set equal to the preferred number

Llamas of one or another row R. These nominal sizes are

base, in relation to which the tolerances are assigned

resolved deviations. Actual deviations must be in

tolerances, and this estimates the accuracy of the manufactured

products.

Graduation tolerances implemented in the form of a set of classes

or degrees of accuracy. The degree of accuracy is understood to be

Bathiness of tolerances corresponding to one relative

level of accuracy for a certain number of nominal

sizes. The degree of accuracy of the geometric dimensions (

tolerance value expressed in micrometers) for

The specified number of nominal sizes is called

qualification and denoted by the letters IT - short for words

ISO Tolerance (ISO tolerance).

Qualification is understood as a set of tolerances,

being measured by constant relative accuracy for all nominal

the size of the set range. In other words, qua

Litet - the characteristic of the accuracy of the product (for example

measures, details) defining the appropriate methods and means

processing and quality control processing. Unified system

tolerances and landings (ESAP), based on a system of tolerances

ISO, for sizes from 1 to 10 000 mm, 19 qualities are set.

Designations of a consistent series of qualifications, in order of

The tolerance for the nominal size is: IT01, ITO, IT1,

IT2, IT3 ... IT17.

3. The ratio between

qualimetric scales

Characteristics, parameters or quality characteristics

objects, measured on a scale of names or on a scale of

Rows are qualitative, i.e. not determined by their use.

muddy magnitude and the magnitude of the differences between them.

Qualimetric scales and types of characteristics measured by them

Quality marks are given in Table. 2

table 2

Qualimetric scales and types of quality characteristics

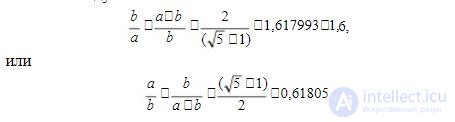

If according to the results of a comparative analysis (Table 2)

rank qualimetric scales by their functional

opportunities, we’ll probably get the next ordinal

a series of decreasing their significance (quality) (Fig. 2):

Fig. 2. Order of decreasing significance qualimetric scales

However, each of the qualimetric scales has its own

their field of application, and therefore they are often not

mozamenyaemy when solving a particular measurement problem

4. Features of measurement in qualimetry

Any measuring scale must have a corresponding

General gradation - division, intervals. This is necessary in order

that on the scale of measurements it was possible to fix the

measurement result and remove the count of the obtained value. Right-

fine scale gradation increases accuracy

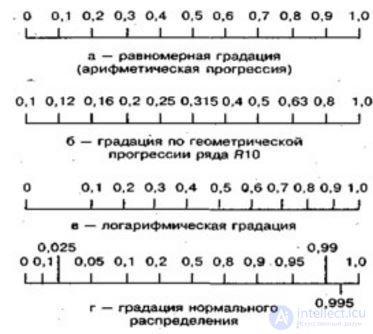

measurements. When constructing measuring scales use

gradations of arithmetic or geometric progression, log

rhymic scale or scale of exponential distribution

as well as the scales of the probability distribution of the measured

quantities, such as scales of normal distribution,

Punch, Bernoulli or other grades convenient for measurements

Dation

Since the quality level and many private (single) ha-

Characteristics (indicators) of quality have values in the range

from zero to one, some of these are most commonly used.

The scales used are given in fig. 3

Fig. 3. Types of gradation of measuring scales

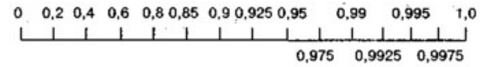

To ensure the accuracy of measurements and evaluation in

It is recommended to use combinations of different types of

within the same scale, or change the frequency and scale of the

increasing it near the limit values of the measured

sizes (Fig. 4).

Fig. 4. Scale model with combined gradation

Thus, the choice of scale for measuring quality or

individual properties of objects, as well as its graduation depend on

the nature of the object, from the goals and objectives of the measurements, from the

methods and measuring instruments, from accuracy requirements and from other

specific conditions of qualimetric research.

Measurement - Acquisition by Means

the numerical value of the size characterizing one or

how many properties of an object (object, process, phenomenon) and satisfaction

meeting the requirement of uniformity of measurements.

The term “measurement” is often referred to as a tool procedure.

mental determination of absolute or specific values

(relative) numerical characteristics of individual properties.

Length, weight, time, etc. well defined numerically. But

comfort, intelligence and other properties do not possess sufficient

a certainty to be measured, and therefore

they are rated. Evaluation differs from measuring more

uncertainty of the result.

Determination of the values of the measured properties

mine is not instrumental, called evaluation.

All types of measurements are divided according to the methods of obtaining

results for groups: direct, indirect, cumulative and joint.

Straight lines are measurements, the result of which is semi-

directly from the experimental data. For example, measuring

air temperature with a thermometer, electric current

ka ammeter, time lapse stopwatch.

Indirect measurements are those in which the desired

the value is not directly measured, but its value is found

based on the known relationship between this value and

values obtained as a result of direct measurements. When-

measure is the determination of the volume of the body according to the results of its direct

linear measurements of linear dimensions. The result of indirect

measurement is, for example, the material strength:

σ p = Fmax / F

where Fmax is the breaking force;

Fo is the cross-sectional area of the sample before it is tested on

gap.

Aggregate measurements are measurements of several

native values in their various combinations, the values of which

determined by solving a system of relevant equations.

In this case, the required size value is obtained by comparing

the comparison of the measured values with the known. Example

is the determination of the masses of individual bodies when the mass is known

one of them.

Joint measurements - simultaneous measurements of two

or several non-uniform values, to establish the dependence

between them. For example, based on two simultaneous

measurements (temperature and size) determine the

linear expansion of solids. Also joint

measurements determine the rate of change of something.

Depending on the principles and means used

measures are divided into methods of direct assessment and

Toda comparison. The method of direct reference is called

the method by which the measured quantity is determined directly

without any additional actions and without calculating

leny, by counting or removing the indicator from the measuring

device (tool). The comparison method is a measurement method

the measured value is compared to the known

base or reference value, i.e. with measure. Results of measurement

rhenium is expressed in natural units or in

dimensional units.

The method of comparison with the measure is divided into the following:

1. The opposition method , or the null method, is

method of comparison of the measured value with the measure, in which the

the measured quantity is balanced by the corresponding dimensional

by size. An example of such a measurement method is to determine

body weight on a scale of arms or measurement of electrical

go resistance with a balancing bridge.

2. The difference method is also a method of comparison with a measure,

but at which the difference between the measured value is determined

known value, reproducible measure. With diff

partial measurement method, an incomplete

raising the measurand, and this is the difference

differential method from zero.

3. Нулевой метод - в этом случае разность доводят до нуля,

как, например, при балансировке измерительного моста.

4. Метод замещения - это метод сравнения с мерой, при

котором измеряемая величина Qx заменяется известной величи-

ной Qo . Величина Qo легко воспроизводима мерой [ Q ]. Измеряе-

мая величина соответствует известной величине, т.е. Qx = Qo .

Примером такого измерения является взвешивание тел на отта-

рированных (с указателем веса) пружинных весах. Здесь вес из-

меряемой массы замещает вес тарировочных (известных) грузов.

Измерения классифицируют по различным признакам:

по точности измерений, по числу измерений в серии, по отноше-

нию к изменению измеряемой величины, по назначению, по фор-

ме выражения результата измерений и т.д.

Равноточные измерения - измерения с равной точностью

определения измеряемой величины, выполняемые одинаковыми

по точности средствами в одних и тех же условиях.

Неравноточные измерения - это ряд измерений какого-

либо размера, выполненных различными по точности средствами

измерений и (или) в разных условиях.

Однократное измерение - измерение, выполненное один раз.

Многократное измерение - измерение одного и того же

размера, результат которого получают из нескольких последова-

тельных измерений, т.е. это измерение, состоящее из ряда одно-

кратных измерений.

Статическое измерение - это измерение, когда измеримая

величина принимается, в соответствии с условиями измерительной

задачи, за неизменную на протяжении времени измерения.

Динамическое измерение - определение изменяющейся с

течением времени величины размера. Такое изменение размера

измеряемой величины требует фиксации момента времени.

Физико-технические или технические измерения - измере-

ния при использовании единиц физических величин.

Социально-экономические измерения

- это определения

(оценивания) показателей, относящихся к социальным и эконо-

мическим субъектам и процессам.

Метрологические измерения - измерения с помощью этало-

нов и образцовых средств измерений, рабочих единиц физичес-

ких величин для передачи их размера технические средствам из-

мерений, а также поверочные измерения для определения

погрешностей измерительных средств.

Абсолютное или фундаментальное измерение - это прямое

измерение одной или нескольких физических размеров свойств

с использованием основных натуральных единиц измерений и

(или) значений физических констант.

Относительное измерение - измерение отношения изме-

ряемой величины к одноименной величине, играющей роль еди-

ницы измерения, или измерения изменяемой величины по от-

ношению к одноименной величине, принимаемой за исходную

(эталонную, базовую).

Несмотря на значительное количество различных методов из-

мерения очень важным является соблюдение принципа единства.

Под единством измерений понимается такое их осуществ-

ление, которое обеспечивает достоверность и сопоставимость

результатов однородных измерений, а значения измеряемых ве-

личин при этом выражаются в узаконенных и общепринятых

единицах. Вся общественная практика деятельности людей и

особенно их познавательный процесс требуют одинаковости,

единства сходных по сути измерений. Поэтому возникали раз-

личные единицы измерений - меры.

Первая международная Генеральная конференция по мерам

и весам (ГКМВ) состоялась в 1889 г. На этом форуме Россия по-

лучила два эталона метра из платино-иридиевого сплава. Length

1 метр на эталонах отмечалась штрихами.

Последний Закон «Об обеспечении единства измерений»

был принят в нашей стране 27 апреля 1993 г. Этот Закон Россий-

ской Федерации устанавливает правовые основы обеспечения

единства измерений в Российской Федерации, регулирует отно-

шения государственных органов управления Российской Федера-

ции с юридическими и физическими лицами по вопросам изго-

товления, выпуска, эксплуатации, ремонта, продажи и импорта

средств измерений и направлен на защиту прав и законных инте-

of citizens, the established legal order and the economy of Russia

the Russian Federation from the negative effects of inadequate

measurement results

Comments

To leave a comment

Qualimetry reliability and quality

Terms: Qualimetry reliability and quality