Lecture

5. THE ORDER OF SOLVING THE RELIABILITY TASKS

5.1. Assumptions

The reliability of a technical object of any complexity should be ensured at all stages of its life cycle: from the initial stage of the design development to the final stage of operation. The basic conditions for ensuring reliability are in strict compliance with the rule, called the reliability triad: reliability is laid during design, is ensured during manufacture, and is maintained in operation . Without strict implementation of this rule, it is impossible to solve the task of creating highly reliable products and systems by compensating for the defects of the previous stage for the next.

If the design process does not properly resolve all issues of creating a device or system with a given level of reliability and does not incorporate design and circuit solutions to ensure trouble-free operation of all elements of the system, then these disadvantages sometimes cannot be eliminated during the production process and their consequences will lead to low system reliability in operation. In the process of creating a system, all solutions, designs and instructions of the designer (designer) must be fully implemented.

Operation is important in maintaining, or rather in implementing the required level of reliability. During operation, the conditions and rules for the use of devices, such as electrical installations, must be followed; timely take measures to study and eliminate the causes of identified defects and faults; analyzed and summarized the experience of using devices.

Typically, for typical mass production devices (transformers, switches, disconnectors, etc.), the manufacturer sets the basic reliability indicators: average time to failure; failure rate; average recovery time; technical resource, etc. [14, 18, 19].

Obviously, in any enterprise there should be a reliability program developed for each stage of the device (system) life cycle. One of the most important documents, largely guaranteeing the preservation of a high level of reliability of electrical installations in operation, is the “Rules for the operation of electrical installations of consumers” [16].

5.2. Reliability calculation methods

Each stage of development or modernization of the system corresponds to a certain level of reliability calculation. As a rule, there are three levels of calculation: approximate; indicative; final. In tab. 5.1 shows the approximate relationship between the stages of development and the levels of calculation of the reliability of automation systems and semiconductor technology [15, 17].

At the stage of approximate and approximate calculations, it is assumed that the object (system) is assembled according to the basic scheme, the failure rate of all elements does not depend on time,  = const. Failures of elements occur randomly, any failure does not cause changes in the characteristics (working capacity) of elements, except for the failed one, that is, the flow of failures is accepted as simple.

= const. Failures of elements occur randomly, any failure does not cause changes in the characteristics (working capacity) of elements, except for the failed one, that is, the flow of failures is accepted as simple.

Under actual operating conditions, the elements from which the system is assembled often end up in conditions significantly different from the calculated (nominal) ones. This circumstance affects both the reliability of the elements and the system as a whole.

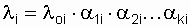

For electrical installations, the most significant factors are: electrical load and the rate of its change; mechanical effects (vibration, shaking, shock); ambient humidity; the presence of dust in the air, etc. Most often, these factors are taken into account with the help of appropriate correction factors. Taking into account the correction factors, the failure rate of the element is determined by the expression

at

at  , (5.1)

, (5.1)

Where  - failure rate of the i-th element in nominal conditions;

- failure rate of the i-th element in nominal conditions;  - correction factor taking into account the effect of electrical load on the i-th element;

- correction factor taking into account the effect of electrical load on the i-th element;  - correction factor taking into account the influence of the ambient temperature on the i-th element.

- correction factor taking into account the influence of the ambient temperature on the i-th element.

Thus, other factors are taken into account.

Table 5.1

Stages of development and levels of reliability calculations

Development of technical specifications | Approximate calculation to determine the reliability standards |

| Estimated calculation of reliability standards | |

| The final calculation taking into account the operating modes of the elements and factors affecting the system | |

| The final version of the calculation taking into account additional factors depending on the adopted schematic and design solutions | |

|

Table 5.2

Ratios that take into account the impact of external factors

|

|

|

|

| Laboratory | |||

| Station Field | |||

| Delivery van | |||

| Railway |

Let us analyze the main causes of failures in the most common elements of automation and power supply systems.

Resistors are the most commonly used elements. Their reliability is quite high. For these elements, the most common failure mode is breakage. Statistics show that over 55% of resistor failures occur due to breaks and

35-40% - due to the burning of the conductive element, that is, 90-95% of the failures are associated with an open resistor circuit.

Capacitors, like resistors, are widespread in automation circuits. The most common type of capacitor failure is dielectric breakdown and insulation overlap between the plates (surface discharge). The failure of a "short circuit" capacitor is about 50% of all failures.

In high-voltage measuring and power transformers, failures are most often caused by interwinding and layer insulation breakdown. The decrease in the dielectric strength of the insulation is associated with low moisture resistance of the winding materials, accelerated aging of the dielectric, which is under the influence of randomly varying temperature and humidity. For transformers and chokes, this dependence can be expressed using temperature coefficients of failure rates, the values of which depend on the type of transformer [13, 17, 19].

In semiconductor devices - diodes, transistors, thyristors, microcircuits, gradual and sudden failures occur more often than other types of failures. The most characteristic change in the parameters of semiconductor devices, leading to gradual failures, is an increase in the reverse current of the diodes and uncontrolled reverse currents of the collector junction of transistors and thyristors. Sudden failures are the result of errors in the design of semiconductor devices and violations of their manufacturing technology. On the basis of data on the operation of semiconductor devices in various circuits, it can be assumed that about 80% of their failures are gradual. In reference books, in particular in [15, 19], influencing factors on the performance of semiconductor devices in the form of correction factors determined from tables or nomograms are rather widely taken into account.

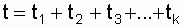

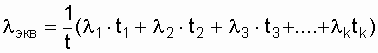

Calculation of reliability is recommended in the following order.

will be

will be  .

.

Calculations are offered in the form of a technical report, which should contain:

1) a block diagram of reliability with a brief explanatory text;

2) the formulation of the concept of system failure;

3) calculation formulas for determining quantitative indicators of reliability;

4) calculation of reliability indicators, summarized in tables and graphs;

5) an assessment of the accuracy of the calculation with the rationale for the adopted mathematical models (see Section 8);

6) conclusions and recommendations.

Comments

To leave a comment

Theory of Reliability

Terms: Theory of Reliability