Lecture

the introduction of solid (usually crystalline) dye under the surface of the paper.

Thermosublimation printing is based on the phenomenon of sublimation, the transition of a substance from a solid to a gaseous state, bypassing the liquid state.

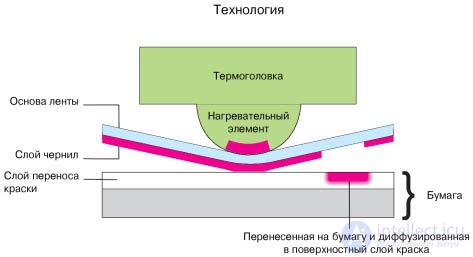

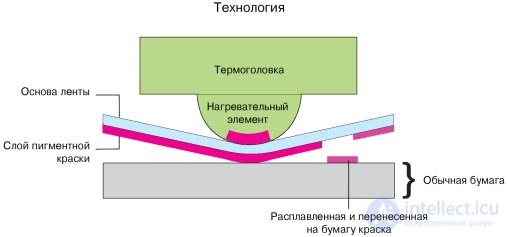

Inside the thermal sublimation printer is a heating element. Between it and a special thermal photographic paper, a special film is drawn, similar to an ordinary transparent cellophane. In this film are enclosed dyes of three colors - cyan, magenta and yellow. When a print job arrives, the film begins to heat up; reaching a certain temperature limit, the paint evaporates from the film. When heated, the pores of the paper open and easily “seize” a little cloud of ink; after printing is completed, they close, reliably fixing the pigment particles. Printing is carried out in three passes, because the ink is applied to the paper alternately. Many modern models of printers complete the photo printing with an additional run, during which the print is covered with a special film to protect the paint from fading or fingerprints.

Thermosublimation printing allows you to get photos of excellent quality. There is no raster or banding, as when printing on inkjet printers. In addition, the image is uniform, the border between the ink drop and paper can not be seen - due to the absence of this drop. Such photos are very resistant to fading, because the paint is not on paper, but as it were “soldered” into it. Another advantage is the huge color palette that the user has. The more heated the film, the more dye evaporates and is transferred to the paper. By adjusting the degree of heating, you can reproduce the smallest nuances of color - from the lightest, barely distinguishable with the naked eye, to saturated dark.

It should be divided household devices for personal use class Samsung SPP-2040 and professional devices such as Fujifilm ASK-2500. In the first case, there will be a reasonable price for the device itself, but an extremely high cost of printing. In the second case, the relatively high price of the device will be compensated by an acceptable price of the finished print.

Surely each of us at least once in his life met these names: in advertising, in a store or elsewhere. However, not every PC user can easily answer what a sublimation or sublimation printer is.

Let's start with the fact that these concepts are identical, and, speaking of the printer for sublimation printing, you can either use the first part of the thermal one, or even do without it. The printer got its name due to the phenomenon on which the principle of its operation is based - sublimation - that is, the transition of a body from a solid to a gaseous state, bypassing the liquid state.

The principle of operation of a sublimation printer is as follows: a special film (similar to a plastic bag) contains 3 dyes (cyan, magenta, and yellow), when heated, the paint evaporates from the film and enters the enlarged pores of the paper, after cooling the pores close, and the ink turns reliably " sealed. " Printing is done in 3 stages, as the paints are applied alternately; sometimes there is an additional, protective layer. Due to the fact that the ink is applied in a special way, each point has no clear outlines, a kind of "squares", so the printed photo on the sublimation printer has a special quality.

The price of a sublimation printer is very high. They are almost never used for normal printing of pictures and photos. In addition to the direct price of a dye-sublimation printer, you will be faced with expensive supplies for sublimation printers. As a rule, firms dealing with printing business cards, calendars, drawing images on CDs , DVDs, or very large companies can buy a sublimation printer . Most sublimation printers print photos in a small format, but now A4 sublimation printers are becoming increasingly popular. Today, along with color dye-sublimation printers appear black and white, allowing text printing.

For home use, you can buy a dye-sublimation printer if you want to preserve the memory of important events for a long time, and at the same time you cannot periodically go to the photo lab. Of course, printing every photo on such a printer is quite expensive, since both paper and cartridges for dye-sublimation printers are not cheap; only special, most expensive photos are worth it. Photo printed on a sublimation printer, timeless. It does not fade, it is very durable and scratch-resistant and free from hand marks. And the best quality inks provide protection even from ultraviolet radiation.

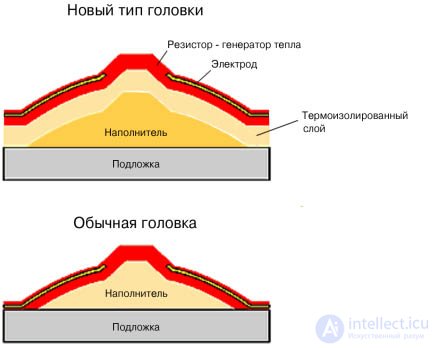

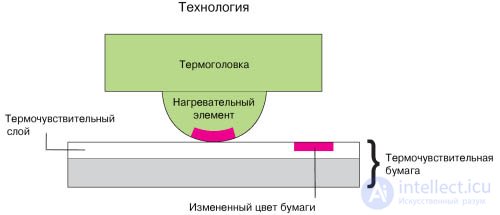

ALPS has developed a highly efficient thermal head with low power consumption. Based on its achievements in the field of creating new materials, ALPS has developed a new head with elongated electrodes. A feature of this head is a significant reduction in heat dissipation at a lower power consumption.  STRUCTURE OF A NEW TYPE OF HEAD The precision tape feed mechanism on the basis of helical gears can significantly reduce the size of the printer with high print quality. Decreased print quality due to uneven paper feeding can be avoided by simultaneously reducing the size and feed mechanism. To this end, ALPS has developed a new type of gears, taking advantage of their achievements in the field of precision mechanics. The new type of gears is called helical (JGMA standard), and the mechanism using gears of this type allows to get high print quality.  PRINCIPLES AND FEATURES OF THERMAL PRINTERS Modern thermal printers use several technological features, which are described below. Thermal printers with direct printing  Changing the color of the paper is carried out by heating it with a thermal head. Thermographic printer sublimation type  Due to the thermal head, the ink evaporates and diffuses into the paper. Features Adjusting the temperature of the heating element allows you to change the saturation of the printed points. Gradations of saturation  Since the printed dots are very small, the print quality is much higher. If you wish, you can achieve quality photos. Thermal printer on the principle of melting paint  The heating element evaporates the ink, which is transferred to the paper. Features Clear print even on plain paper. Since pigment paint is used, the print is resistant to moisture and light. Adjusting the temperature of the heating elements allows you to change the size of the points. Variable Point Technology  Possible options The printing process is very economical (consumption ranges from 1/3 to 1/4 of the sublimation method). Thermal heads, as the main element of thermal printer, are constantly being improved, which allows increasing the efficiency of all thermal printing systems while reducing power consumption and increasing print speed. |

Comments

To leave a comment

Electromechanical devices of electronic devices

Terms: Electromechanical devices of electronic devices