Lecture

Laser Printer 1993 Apple LaserWriter Pro 630

Kyocera FS-1110 Laser Printer

Fuji Xerox color laser printer C1110B

A laser printer is a type of printer that allows you to quickly produce high-quality text prints and graphics on plain (non-special) paper. Like photocopiers, laser printers use the xerographic printing process in their work, but the difference is that image formation occurs by direct exposure (illumination) of the photosensitive elements of the printer by the laser beam.

Prints made in this way are not afraid of moisture, resistant to abrasion and fading. The quality of this image is very high.

If the history of inkjet printing is full of science and is full of research and discovery, then the history of the creation and development of laser printers is probably more businesslike and to a certain extent related to marketing rather than science.

In 1938, a law student, Chester Carlson (who, by the way, became a patent attorney in the future to reinforce his inventive talents), received the first xerographic image, which was a successful result of many years of his work, which began because of his dissatisfaction with existing mimeographs and the high cost of prints obtained. The word "xerography" itself was formed from the Greek words "dry" and "write." And the meaning of the new technology was to use static electricity to transfer dry ink (toner) to paper.

However, only after 8 years, having been refused by IBM and even by the US communications troops, in 1946, Carlson managed to find a company that agreed to produce electrostatic copiers invented by him. This company was the Haloid Company, which later evolved into the well-known Xerox Corporation.

The first Xerox device entered the market in 1949 under the name Model A. It was a very cumbersome and complex device. To get him a copy of the document, it was necessary to manually perform a series of operations. And only ten years later, the fully automatic xerograph Xerox 914 was commercialized, which was capable of producing 7 copies per minute. This model became the prototype of all copiers and laser printers that appeared later.

On the creation of laser printers Xerox began to work in 1969. Success was achieved in 1978 by employee Gary Starkuezer, who was able to add a laser beam to the technology of existing Xerox copiers, thus creating the first laser printer. Full duplex Xerox 9700 could print 120 pages per minute (by the way, it still remains the fastest laser printer in the world). However, the dimensions of the device were simply enormous, and the price of 350 thousand dollars (without an amendment to the course at that time) did not fit the idea of “a printer into every home”.

In the early 80s, the demand for devices that exceed existing dot matrix printers in print quality reached a critical level. In 1979, the offer was followed by Canon, which introduced the first desktop laser printer LBP-10. The following year, the company privately demonstrated the new LBP-CX model from California-based Apple, Diablo and HP.

At that time, Canon required strong marketing partners for its products in a new market for the company, as the company had strong positions in the field of cameras and office solutions (the same copiers), but did not have the connections necessary for effective sales in the data processing market. Canon first turned to Diablo Systems, a division of Xerox Corporation. This was obvious and logical, since Diablo owned most of the market for petal printers, and its marketers expressed a desire to put the Diablo logo on products from other manufacturers. Thus, Xerox was the first company that was invited to market the CX system with a Canon controller.

However, Xerox rejected this proposal because, together with the Japanese Fuji-Xerox, she was engaged in the development of a device that was planned to be the best desktop laser printer on the market. But, although the new model 4045 combined a copier and a laser printer, it weighed about 50 kilograms, cost twice as much as the CX, did not have a replaceable toner cartridge and provided not the best print quality. Subsequently, the former Diablo marketers admitted that it was a pretty big mistake for Canon to miss, and the HP LaserJet printer that came out a little later could be the Xerox LaserJet.

In any case, after Diablo rejected the offer of Canon in Fremont, representatives of the latter, after traveling a few miles, visited HP offices in Palo Alto and Apple Computer in Cupertino. Hewlett-Packard was the second logical choice, because it worked closely with Diablo and had fairly wide lines of dot-matrix and petal printers.

The collaboration between Canon and HP was the release in 1984 of a LaserJet printer capable of printing 8 pages per minute. Their sales grew rapidly and led to the fact that by 1985, Hewlett-Packard had taken over almost the entire market for desktop laser printers. It should be noted that, as in the case of inkjet printers, new devices became truly available only after the development of replaceable toner cartridges for them (in this case, the developer was Hewlett-Packard).

At the same time, the questions of cheapening new and recycling used cartridges, the number of which began to hint at environmental problems, gave rise to a whole branch of the processing industry, the date of birth of which can be considered 1986.

There are three ways to transfer toners:

In the two-component system, the developer remains on the magnetic shaft of the development unit and continues to serve further (the toner is naturally consumed). In the technical descriptions of many devices, manufacturers declare that the developer does not need to be replenished at all, however, in practice, its performance deteriorates over time, which affects the quality of copies.

Toner - powder for drawing an image.

The carrier (eng. Carrier) is a ferromagnetic powder (the structure is fine particles) used in two-component machines to hold the toner on the surface of the magnetic shaft due to electrostatic forces (when mixed with toner it charges it with positive static potential under mutual friction), and from there , under the influence of the discharge on the corotron - on the surface of the photodrum; moreover, the developer, due to its magnetic properties, remains on the magnetic shaft and is almost not consumed (however, it loses its properties over time and also requires replacement). [3]

Developer (eng. Developer) (sometimes called a starter) - a mixture of materials supplied to the photodrum. In two-component machines, this is a mixture of toner and carrier, and in single-component machines, only toner. The term is similar to the term “developer” used in photography, but usually it is not translated in Russian-language literature.

The process of laser printing consists of five consecutive steps:

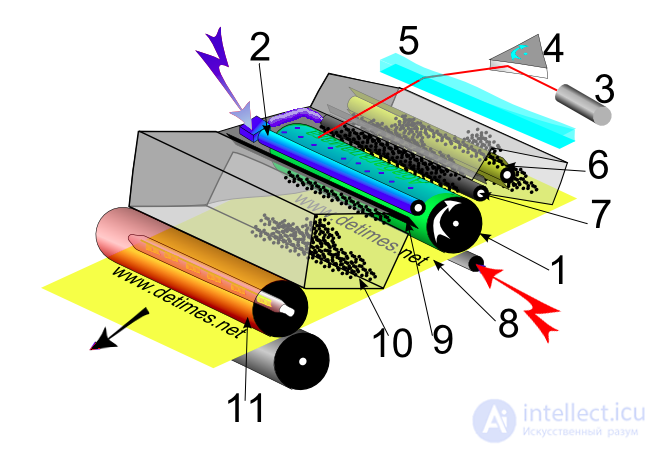

Laser printing process

Photovolt charging - applying a uniform electric charge on the surface of a rotating photodrum (1). The most commonly used photodrum material, photoorganic, requires the use of a negative charge, but there are materials (for example, silicon) that allow the use of a positive charge.

Initially, charging was performed using a corotron (English scorotron ) - a tensioned wire, which is supplied with voltage relative to the photodrum. Between the wire and the photo drum is usually placed a metal grid, which serves to equalize the electric field.

Later they began to use charging with a charging roller (English Charge Roller ) (2). Such a system allowed to reduce the voltage and reduce the problem of ozone emission in the corona discharge (conversion of O 2 molecules to O 3 under the action of high voltage), however, it involves the problem of direct mechanical contact and wear of parts, as well as cleaning from contamination.

Laser scanning (light exposure) - the process of passing the negatively charged surface of the fototal under the laser beam. The laser beam (3) is deflected by a rotating mirror (4) and, passing through the distribution lens (5), focuses on the photo-beam (1). The laser is activated only in those places where the toner should be released from the magnetic shaft (7). Under the action of the laser, the areas of the photosensitive surface of the photovalue, which were illuminated by the laser, become electrically conductive, and part of the charge in these areas “flows” onto the metal base of the photovalue. Thus, an electrostatic image of the future print in the form of a “pattern” of areas with a less negative charge than the general background is created on the surface of the photovaly.

A negatively charged roller when applying toner gives the toner a negative charge and feeds it to the development roller. The toner in the hopper is attracted to the surface of the magnetic shaft by the action of the magnet from which the shaft core is made. During rotation of the magnetic shaft, the toner on its surface passes through a narrow slot formed between the metering blade and the magnetic shaft. After that, the toner comes into contact with the photocell and is attracted to it in those places where a negative charge remains. It is a very common misconception that the toner is attracted precisely to the places where there is no charge on the photo sheet. However, the toner, being a dielectric, is electrified into dipole-charged particles that are attracted to any charged surfaces, regardless of the sign of the charge of the latter. The toner will be able to hold on to the photo in places with no charge, if the toner particles are charged (and no matter with what sign). At the same time, the opposite misconception is that the toner is attracted to negatively charged places. Most brands of manufactured toners for household laser printers are marked as negatively charged, which indicates the impossibility of attracting negatively charged toner particles to similarly charged areas of the photodrum. Therefore, in fact, a negatively charged toner cannot be attracted to all charged areas, regardless of the sign of the charge, but only to those that have no charge, or at least to those whose charge does not prevent the formation in the surface layer. photodrum of the dipole moment under the influence of the electrostatic field of negatively charged toner particles.

Thus, the electrostatic (invisible) image is transformed into a visible (manifest). The toner attracted to the photo film moves further on until it comes in contact with the paper.

At the point of contact with the photo paper, there is another video clip under the paper, called a transfer roller. He is given a positive charge, which he reports and the paper with which he contacts. Toner particles, having come into contact with positively charged paper, are transferred onto it and held onto the surface by electrostatics.

If you look at the paper at this moment, a completely finished image will be formed on it, which can be easily destroyed by swiping it with your finger, because the image consists of toner powder attracted to the paper, nothing other than electrostatics is held on paper. To obtain the final print image must be fixed.

The paper with the “poured” toner image moves further to the fixing unit (stove). The image is fixed by heating and pressure. The stove consists of two shafts:

Thermal sensor (thermistor) monitors temperature. The stove consists of two contacting shafts between which the paper passes. When the paper is heated (180–220 ° C), the toner attracted to it melts and squeezes in a liquid form into the paper texture. Coming out of the stove, the toner quickly freezes, which creates a permanent image that is resistant to external influences. So that the paper on which the toner is applied does not stick to the thermowal, paper separators are made on it.

However, thermals - not the only implementation of the heater. An alternative is another stove device in which a thermofilm is used: that is, a special flexible material in the form of a tube that completely wraps the supporting structure with a thin and long ceramic plate, which is just a heating element containing, in the structure of the ceramic plate itself, built-in low-voltage temperature control sensor on the other side of the plate. The erroneous installation of a ceramic plate by unskilled employees of a service center leads to a rapid and irrevocable burn-out of the thermal sensor.

For example, this is true for the HP LaserJet 1100 / 1100A, 1200 series laser printers, which were remarkable in their time. In subsequent models of printers (HP LJ 1010,1018,1020, etc.), the thermal sensor is removed from the structure of the ceramic plate.

In this version of the stove with a thermal film, it is necessary to use a special high-temperature silicone lubricant due to the presence of considerable effort during friction and sliding on ceramics during the rotation of the thermal film when the sheet passes through the thermoblock.

Thermofilm mainly rests and rotates on its side plastic support racks on its side.

It should be noted that there are the following disadvantages inherent in all types of thermofilms. This is their tendency to break through stapler clips on paper, burns due to sticking of caked toner on excess thermal grease inside the frame of the hub under the film and the presence of other negative effects of hapless users and service repairmen.

The principle of multi-color laser printing is as follows. At the initial stage of the printing process, the rendering engine takes a digital document and processes it one or more times, creating its page-by-page raster image, decomposed into color components, corresponding to the colors of the used toners. At the second stage, a laser or an array of LEDs forms a charge distribution on the surface of a rotating photosensitive drum, similar to the resulting image. Charged fine particles of toner, consisting of coloring pigment, resins and polymers, are attracted to the discharged parts of the drum surface.

Next, the drum is in contact with the paper, and the toner is transferred onto it. Most color laser printers use four separate passes corresponding to different colors. Then the paper passes through the “stove”, which melts the resins and polymers in the toner and fixes it on paper, creating the final image.

Lasers are able to focus precisely, resulting in very thin rays that discharge the necessary parts of the photosensitive drum. Thanks to this modern laser printers, both color and black and white, have a high resolution.

Benefits

Как правило, разрешение при чёрно-белой печати варьируется от 600x600 до 1200x1200 точек на дюйм, однако при цветной печати достигает 9600x1200. Цветные и чёрно-белые лазерные принтеры работают на практике одинаково. Отличие заключается в том, что для цветной печати используются четыре типа красящего тонера. Любой цвет вносит свою лепту в окончательное изображение, наносимое на лист бумаги. По сравнению со струйными принтерами, лазерные имеют немало преимуществ:

disadvantages

Скрытые метки (см. Жёлтые точки) — многие модели цветных принтеров при печати наносят на оттиск скрытое изображение , указывающее на дату и время печати, а также серийный номер устройства, что предположительно сделано с целью пресечь печать цветных копий денежных знаков и других документов и ценных бумаг [4] .

The image obtained with the help of modern laser printers (as well as matrix and inkjet), consists of dots. The smaller these points and the more often they are located, the higher the image quality. The maximum number of dots that a printer can print separately on a 1 inch (25.4 mm) segment is called resolution and is characterized in dots per inch (dpi - dot per inch). A printer is considered good if its resolution is 300 dpi (300 x 300 dpi is sometimes used, which means 300 dpi horizontally and 300 dpi vertically).

Laser printers are less demanding on paper than, for example, inkjet, and the cost of printing one page of a text document is several times lower. In this case, low-cost models of laser and LED monochrome printers are already able to compete in price with high-quality color inkjet printers.

Most laser printers on the market are designed for black and white printing; Color laser printers are very expensive and designed for corporate users.

Лазерные принтеры печатают на любой плотной бумаге (от 60 г/м 2) со скоростью от 6 до ... (эта цифра постоянно растет) листов в минуту (ppm – page per minutes), при этом разрешение может быть 1200 dpi и более. Качество текста, напечатанного на лазерном принтере с разрешением 300 dpi, примерно соответствует типографскому. Однако если страница содержит рисунки, содержащие градации серого цвета, то для получения качественного графического изображения потребуется разрешение не ниже 600 dpi. При разрешающей способности принтера 1200 dpi отпечаток получается почти фотографического качества. Если необходимо печатать большое количество документов (например, более 40 листов в день), лазерный принтер представляется единственным разумным выбором, поскольку для современных персональных лазерных принтеров стандартными параметрами являются разрешение 600 dpi и скорость печати 8...12 страниц в минуту.

For the first time a laser printer was introduced by Hewlett Packard. It used the electrographic principle of creating images - the same as in copiers. The difference was in the way of exposure: in copiers it happens with the help of a lamp, and in laser printers the light of a lamp was replaced by a laser beam (Fig. 1).

Fig. 1. Laser printer device

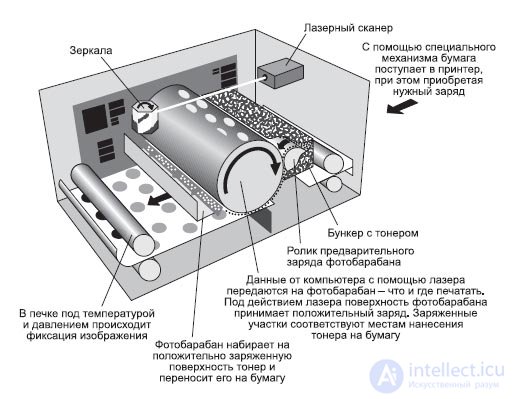

The heart of a laser printer is a photoconductive cylinder (Organic Photo Conductor), often referred to as a printing drum or just a drum. With its help, the image is transferred to paper. The photodrum is a metal cylinder coated with a thin film of a photosensitive semiconductor. The surface of such a cylinder can be provided with a positive or negative charge, which is maintained until the drum is lit. If any part of the drum is exposed, the coating acquires conductivity, and the charge drains from the illuminated area, forming an uncharged zone. This is a key point in understanding how a laser printer works.

Another important part of the printer is a laser and an optical-mechanical system of mirrors and lenses that moves a laser beam over the surface of the drum. The compact laser generates a very thin light beam. Reflected from rotating mirrors (usually a tetrahedral or hexagonal shape), this beam illuminates the surface of the photodrum, removing its charge at the point of exposure.

To obtain a point image, the laser is turned on and off using a control microcontroller. The rotating mirror expands the beam as a line of the latent image on the surface of the photodrum.

After forming the line, a special stepping motor turns the drum to form the next one. This offset corresponds to the vertical resolution of the printer and is usually 1/300 or 1/600 inch. The process of forming a latent image on the drum resembles the formation of a raster on the screen of a television monitor.

Two main methods of preliminary (primary) charge of the photo-cylinder surface are used:

• using a thin wire or mesh, called a "corona wire." The high voltage applied to the wire leads to a luminous ionized area around it, which is called a corona, and gives the drum the necessary static charge;

• using a pre-charged rubber shaft (PCR).

So, an invisible image in the form of statically discharged points is formed on the drum. What next?

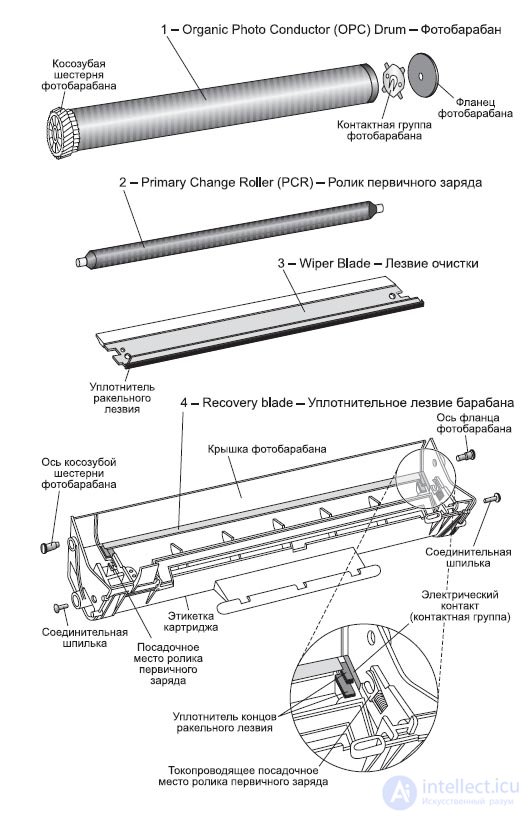

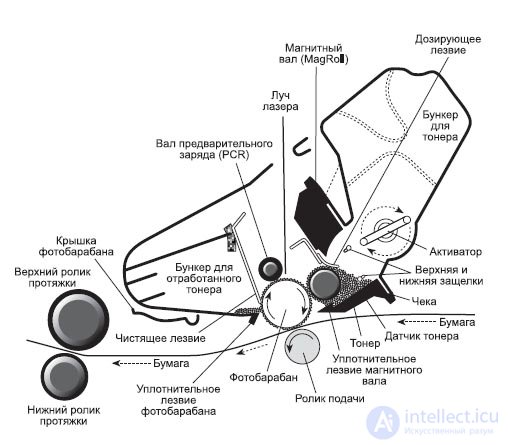

Before we talk about the process of transferring and fixing the image on paper, consider the Hewlett Packard Laser Jet 5L printer cartridge device. This typical cartridge can be divided into two main compartments:

waste toner compartment and toner compartment.

The main structural elements of the waste toner compartment (Fig. 2):

1 - Photo Drum (Organic Photo Conductor (OPC) Drum). It is an aluminum cylinder coated with an organic photosensitive and photoconductive material (usually zinc oxide), which is able to maintain the image of a laser beam;

2 - Primary Charge Roller (PCR) Shaft. Provides uniform negative charge of the drum. Made of a conductive rubber or foam base, deposited on a metal shaft;

3 - "Viper", squeegee, cleaning blade (Wiper Blade, Cleaning Blade). Cleans the drum of toner residue that has not been transferred to paper. Structurally made in the form of a metal frame (stamping) with a polyurethane plate (blade) at the end;

4 - Cleaning Blade (Recovery Blade). Overlaps area between drum and hopper for used toner. Recovery Blade passes the toner remaining on the drum into the bunker and does not allow it to get enough sleep in the opposite direction (from the bunker to the paper).

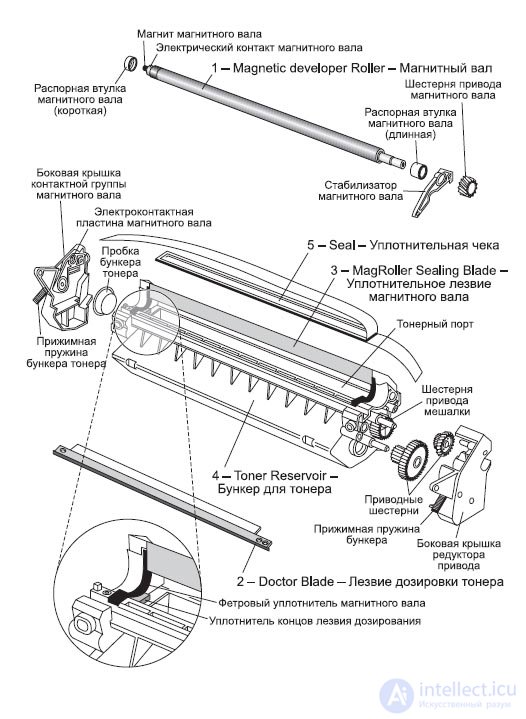

The main structural elements of the toner compartment (see. Fig. 3):

1 - Magnetic Shaft (Magnetic Developer Roller, Mag Roller, Developer Roller). It is a metal tube, inside which there is a stationary magnetic core. Toner is attracted to the magnetic shaft, which, before being supplied to the drum, acquires a negative charge under the action of a constant or alternating voltage;

2 - “Doctor” (Doctor Blade, Metering Blade). Provides a uniform distribution of a thin layer of toner on the magnetic shaft. Structurally made in the form of a metal frame (stamping) with a flexible plate (blade) at the end;

3 - Magnetic Shaft Seal Blade (Mag Roller Sealing Blade). Thin plate, similar to the functions of the Recovery Blade. Overlaps the area between the magnetic shaft and the toner supply slot. The Mag Roller Sealing Blade skips the toner remaining on the magnetic shaft into the compartment, preventing the toner from leaking in the opposite direction;

4 - Toner Reservoir. Inside it is a “working” toner, which will be transferred to paper during printing. In addition, a toner activator (Toner Agitator Bar) is built into the bunker - a wire frame designed to mix toner;

5 - Seal, check (Seal). In the new (or regenerated) cartridge, the toner hopper is sealed with a special seal that prevents toner spills when the cartridge is transported. Before use, this seal is removed.

In fig. 4 shows a cartridge in section. When the printer is turned on, all components of the cartridge come into motion: the cartridge is being prepared for printing. This process is similar to the printing process, but the laser beam does not turn on. Then the movement of the components of the cartridge stops - the printer enters a state of readiness for printing (Ready).

Fig. 4. The cartridge section

After sending the document to print, the following processes take place in the laser printer cartridge:

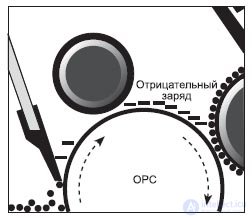

Charging the drum (Fig. 5). The primary charge shaft (PCR) uniformly transfers a negative charge to the surface of the rotating drum.

Fig. 5. Charging the drum

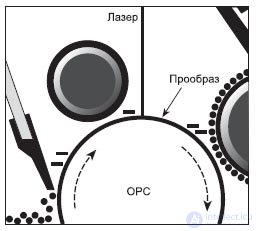

Exposure (Fig. 6). The negatively charged surface of the drum is exposed to a laser beam only in those places where toner will be applied. Under the action of light, the photosensitive surface of the drum partially loses its negative charge. Thus, the laser exposes a latent image on the drum in the form of points with a weakened negative charge.

Fig. 6. Exposure

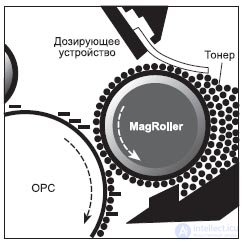

Application of toner (Fig. 7). At this stage, the latent image on the drum with the help of toner is transformed into a visible image that will be transferred to the paper. Toner, located near the magnetic shaft, is attracted to its surface under the action of the field of the permanent magnet from which the shaft core is made. When the magnetic shaft rotates, the toner passes through a narrow gap formed by the “doctor” and the shaft. As a result, it acquires a negative charge and sticks to those parts of the drum that were exposed. "Doctor" provides uniform toner deposition on the magnetic shaft.

Fig. 7. Application of toner

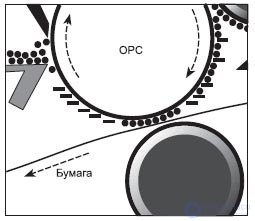

Transferring toner to paper (fig. 8). Continuing to rotate, the drum with the developed image is in contact with the paper. From the back side, the paper is pressed against the Transfer Roller shaft, which carries a positive charge. As a result, negatively charged toner particles are attracted to the paper on which the image is “poured” with toner.

Fig. 8. Transferring toner to paper

Fixing the image (Fig. 9). A sheet of paper with a loose image is moved to the mechanism of fixing, which is a two contacting shaft, between which the paper is drawn. Lower Shaft (Lower Pressure Roller) presses it to the Upper Fuser Roller. The upper shaft is heated, and when it comes in contact with it, the toner particles melt and are fixed on the paper.

Fig. 9. Fixing the image

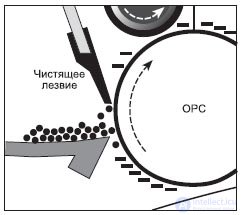

Cleaning the drum (fig. 10). A certain amount of toner is not transferred to the paper and remains on the drum, so it must be cleaned. This function is performed by the "viper". All toner remaining on the drum is wiped off with a viper into a waste toner bin. In this case, the Recovery Blade closes the area between the drum and the bunker, not allowing the toner to wake up on paper.

Fig. 10. Cleaning the drum

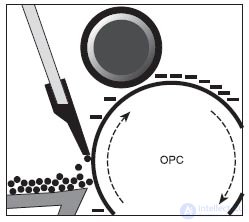

"Erasing" the image (Fig. 11). At this stage, the latent image caused by the laser beam is “erased” from the surface of the drum. With the help of the primary charge shaft, the surface of the photodrum is uniformly “covered” with a negative charge, which is restored in those places where it was partially removed under the action of light.

Fig. 11. "Erasing" images

Comments

To leave a comment

Electromechanical devices of electronic devices

Terms: Electromechanical devices of electronic devices