Lecture

Nowadays it is difficult to find on sale hard drives in retail packaging with documentation, it is even more difficult to figure out what is hidden under the disc cover and what are some of the technologies that are used in production.

Thus, the abbreviation GMR (Giant Magneto-Resistive), which is popular for drive specifications, means the property of super magnetoresistance, which is used in GMR-coating of hard disk heads. And it is the reading devices with GMR layers that allow to increase the memory capacity of the “hard drives” up to several tens and even hundreds of gigabytes on each plate. But let's look under the disc cover ...

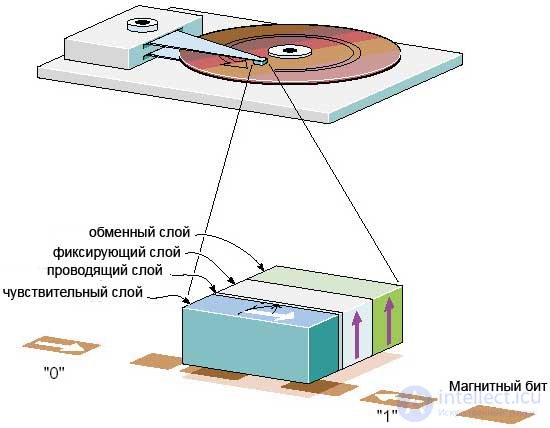

|

| Fig. 1. This is how the hard disk works. |

If we open the hard disk HDA, we will see several mirror disks, a block of magnetic heads for recording and reading information (mounted on the drive), two motors (a spindle of disks and a transport for the reader) and a control unit of sensors (Fig. 1). However, in this article we will be interested only in the design and principles of operation of sensor heads.

|

| Fig. 2. Here, at the very tip of the holder, is the head |

The magnetic head has super slim dimensions and is located at the very tip of the holder (Fig. 2). It is a complex structure consisting of many parts, which are made by photolithography and have linear dimensions in the nanometer region (about 100 nm).

The number of magnetic heads is specified by the manufacturer in the technical documentation for the hard disk, usually from one to six - depending on the number of physical disks and their working surfaces (the disks are both single- and double-sided). The installation and holding of the head on the magnetic track is provided by an electromagnetic positioning system. When spinning magnetic disks, readers rub against the surface of the plates in a special parking zone, which is not used to record information, until a speed sufficient for the sensors to literally soar above the surface is reached.

In the working position, the reading heads are located in fractions of a micron from the surface of the magnetic disk, without touching it (about 0.13 μm, and in the next few years, according to forecasts, this distance can be reduced to 0.05 μm). When the power is turned off, the controller automatically parks the heads, moving them to the parking zone, where the heads safely fall to the surface of the discs.

Modern hard disk sensors are dual, and an inductive head is used to record information. It converts digital data into an alternating magnetic field that magnetizes a portion of the disk. However, it is not suitable for reading information from a disk, since the amplitude of the read signal depends on the speed of movement of the magnetic coating, and the high level of noise makes it difficult to correctly recognize weak signals.

To read the data, MR or GMR heads (Magneto-Resistive — magnetoresistor, Giant Magneto-Resistive — super magnetoresistor) are used, at the tips of which there is either a single-layer MR-sensor or a multi-layer GMR-sensor, respectively. Such sensors are resistors, the resistance of which varies depending on the strength of the magnetic field. Moreover, the amplitude does not depend on the rate of change of the magnetic field, which allows an order of magnitude to reduce the number of errors when reading information from the disk and, as a result, significantly increase the maximum recording density.

A GMR sensor consists of four thin-film (only 1–5 nm thick) layers (Fig. 3):

|

| Fig. 3. The scheme of the structure of the GMR-hard drive head |

The magnetic orientation of the free layer changes in response to small magnetized areas (bits) on the disk, rotating relative to the magnetic orientation of the fixing layer when the data bit on the disk passes under the GMR element.

The direction of the magnetic field inside the fixing layer always remains the same - this is achieved by the functioning of the exchange layer. But in the sensitive layer the direction of the magnetic field changes depending on the direction of the external magnetic field. This in turn leads to a change in the total resistance of the sensitive and fixative layers - the GMR effect works.

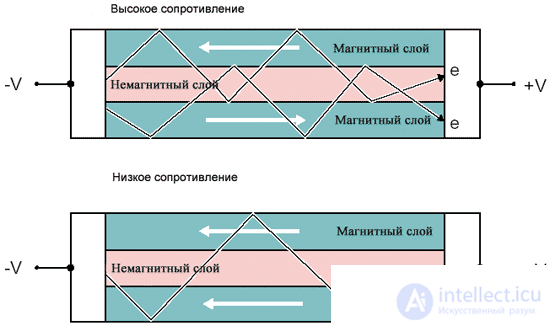

It is based on the quantum properties of electrons, in particular, such a characteristic as spin. The spin of electrons can have only two directions: up and down. Conduction electrons with spin, the direction of which coincides with the direction of the magnetic field inside the GMR medium, experience less resistance when moving and have greater freedom of movement than electrons with spin oriented toward the (oppositely directed) internal magnetic field, which more often collide with the atoms of the medium and therefore experience greater resistance when moving. In the first case, the electrical resistance of the medium will be less than in the second (Fig. 4). The work of the GMR sensor is built on this phenomenon.

|

| Fig. 4. Electron motion in layers of magnetic structure |

When the rotation of the electrons corresponds to the magnetic orientation of the layer in which this occurs, they encounter a lower resistance. As a result, the total resistance decreases and provides a stable signal and high quality information reading. As a result, the recording density on the disc surface can be significantly increased.

You can see an animated model of GMR-head action on the IBM research page on research at http://researchweb.watson.ibm.com/research/demos/gmr/index.html.

According to the parameters GMR-heads are far superior to MR-analogues. GMR-heads can pick up much weaker signals, which allows to increase the storage density of the drive several times. In addition, they are not so noisy, not so susceptible to interference and have a smaller size, despite the multi-layered. All this makes the GMR technology in demand and promising.

The development of technologies used in the heads of hard drives can be divided into several stages:

Comments

To leave a comment

Electromechanical devices of electronic devices

Terms: Electromechanical devices of electronic devices