Lecture

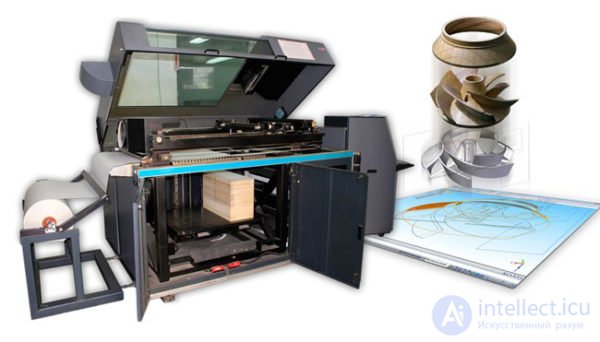

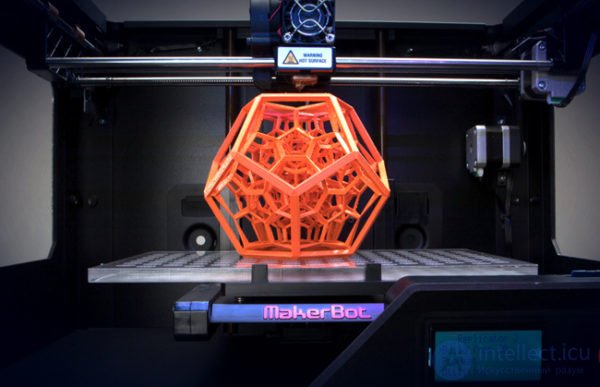

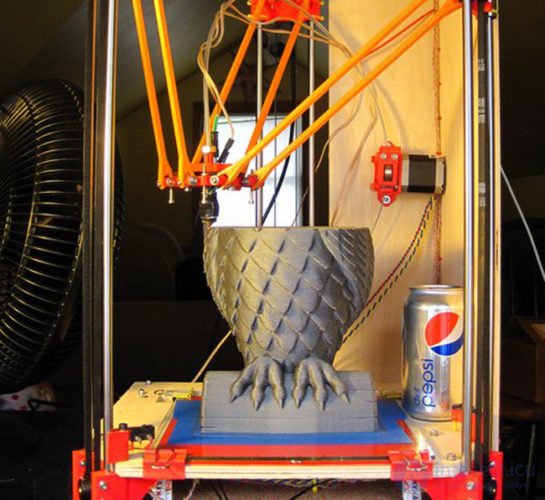

The emergence of 3d printers has opened a new era of technology - it has now become possible to print a large item. The purpose of the resulting three-dimensional products can be very different - from toys to medical prostheses. The basis of the work is taken digital model (or drawing), which is then embodied in its exact real copy. Such devices are found in different capacities and configuration, in home and industrial versions. Existing to date types of 3D printers use a variety of material to get bulk printing.

CONTENT

A consumable consumable determines the types of 3d-printers. Laser aggregates sinter and laminate the powder. Inkjet 3D printer alternately glues the layers of the source material used, then it sintering. The next step is cooling. Here you can use the types of photopolymer plastic, resins, powders, silicone, metal and wax components. Consider how this technique works on different materials.

The principle of operation of the technique is manifested in the following actions:

Such a device is quite possible to assemble with your own hands - it is enough to have the necessary components. Another bonus "in the piggy bank" of such a device is the work with metal powder.

ABS , also known as ABS plastic - Acrylonitrile butadiene styrene - plastic, whose name is formed from the initial letters of the names of substances, as a result of polymerization of which it is formed: acrylonitrile (A) with butadiene (B) and styrene (S). And more specifically, butadiene and acrylonitrile-styrene copolymer (SAN).

SBS Strength , ductility and heat resistance make it a material that is often preferred in engineering and mechanical applications. The modulus of elasticity is much smaller than that of ABS. That is, the printed parts are more flexible. Elongation at break> 250%. The thread, unlike ABS, does not break, not to mention PLA, which is the most fragile of the materials in question. SBS has a flexible structure. It will not break off and will not break when printing. Even if the bar in your extruder is fed at an angle of 90 degrees! The material is transparent (93% light transmission). Coloring the material gives a very beautiful effect. It is processed and dissolved by Limonene, Dichloromethane, solvent. SBS is ideal for printing ceiling light fixtures, prototypes of transparent dishes, bottles, etc.

SBS Not afraid of open air and drafts. Good stick to the table. It is possible to print on a cold table. SBS Watson is well suited for printing large-size layouts. Excellent interlayer adhesion (adhesion between layers) adds strength to printed products. Plastic approved for the manufacture of medical products and children's toys.

SBS does not smell in the printing process. People with a very delicate sense of smell can catch a light smell (from some dyes) within a radius of 30 cm from the hot-end, but no more. Transparent generally has no smell.

SBS does not absorb moisture! You can store it just in the package (so as not to gather dust). The bar does not become brittle from contact with moisture. It is also possible to print dishes from it, it is allowed contact with cold foods.

SBS New and very promising material for 3D printing. Its properties are superior to traditional ABS or PLA. If you give an overall assessment for the materials reviewed, then SBS will take the first place as a universal, non-capricious, comfortable and beautiful material.

PETG for 3D printing

PETG PETG is believed to combine the advantages of ABS - strength, heat resistance, durability, and PLA - ease of use in printing. It is slightly more flexible than ABS and PLA, but more rigid than SBS. The fusion of the layers is usually superb. Low heat shrinkage. You can not be afraid of distortion in print sizes

PETG Similarly, not afraid of open air and drafts. Good stick to the table. Heated the table is optional, but may be useful, especially if there is a distortion of large parts. It is possible to print without heating, but you have to tinker a bit with the settings. Very durable and durable material.

PETG barely smells, at least much less than ABS

PETG is practically unaffected by normal ambient air humidity, so there are no particular problems with printing and storing. And yet, it is good that the filament is stored in as dry a place as possible, next to silicate sachets.

PETG It is called to replace ABS and PLA in the field of 3D printing, surpasses these materials in its properties, is easy to use, durable, safe.

PLA plastic (PLA plastic)

But, the main competitor of ABS plastic is PLA plastic, biodegradable plastic - the so-called aliphatic polyester with a monomer in the form of lactic acid. Such plastic is called bio-compatible, since the main materials for its production are quickly renewable resources, mainly sugar cane and corn.

Manufacturing PLA-plastic. 3D printing materials, 3D plastic printing, 3D plastic printing, 3d printing, 3d-printing, materials for 3d-print, 3d printer, 3D printers, 3d prınter, 3-D printers, 3d printer application, 3d printer device, 3dPLA plastic capabilities. 3D printing materials, 3D plastic printing, 3D plastic printing, 3d printing, 3d-printing, materials for 3d-print, 3d printer, 3D printers, 3d prınter, 3-D printers, 3d printer application, 3d printer device, 3d capabilities

In addition, for the manufacture of biodegradable plastics, such renewable raw materials as starch (potato, corn, tapioca (starchy croup from cassava root tubers), etc.), soy protein, cellulose and some are used. etc. Those that are not hazardous or toxic in production and after use are decomposed into carbon dioxide and water or biomass safe for the environment (during composting).

So, the main advantage of PLA-plastic is that it is non-toxic, therefore, it can be safely used for the manufacture of toys and other products that do not carry a direct threat to human health - food-grade plastic, disposable dishes, etc.

PLA plastic has a lower thread softening temperature than about ABS plastic (about 190 ° C), and printing temperature is from 210 to 250 ° C, which means that it is less energy consuming to work with. In addition, with 3D printing with such plastic it is not necessary to use Kapton (for lubricating the surface to build the prototype). And you do not need to warm up the table for “sticking” of the object built up on it.

Products from PLA-plastic. 3D printing materials, 3D plastic printing, 3D plastic printing, 3d printing, 3d-printing, materials for 3d-print, 3d printer, 3D printers, 3d prınter, 3-D printers, 3d printer application, 3d printer device, 3d capabilities

Another plus is the fairly smooth surface of a product printed from PLA-plastic, good detailing, simple refinement by grinding or other methods that do not require special equipment.

The disadvantages of PLA-plastic for 3D printers include the fact that it is slightly more expensive than ABS plastic. And the fact that it is quite fast (in comparison with durable ABS) loses its original quality, and therefore is only suitable for the manufacture of objects with a limited service life. The term of decomposition of PLA-plastics ranges from several weeks to several years, depending on the brand.

Conventionally, the disadvantages of PLA-plastic can be attributed to the fact that, unlike ABS plastic, it does not dissolve in acetone. But, but pla-plastic is well soluble in phenol, in concentrated sulfuric acid and in a substance called "limonene".

PVA plastic for 3D printing

In fairness, we note that recently a new type of material for 3D printing has appeared on the market - PVA plastic (polyvinyl acetate). In fact, they are familiar to everyone from school lessons in labor PVA glue, although in this case from a dry state, PVA is diluted with water to a certain consistency. And then, with the help of special equipment, it melts and forms into special granules or pva-threads for 3D printing. It’s too early to talk about this type of plastic and its specific advantages over other materials for 3D printing. It appeared on the market only in 2012.

PVA plastic. 3D printing materials, 3D plastic printing, 3D plastic printing, 3d printing, 3d-printing, materials for 3d-print, 3d printer, 3D printers, 3d prınter, 3-D printers, 3d printer application, 3d printer device, 3d capabilities

It is known that PVA-plastic is used as a separator for printed parts, due to the fact that it is well soluble in water. Let us give an example: we print on a 3D printer the parts screwed onto the bolt using pva-plastic and some other plastic (abs or pl). And after printing, we lower the finished prototype of the product for a short time into the water, after which it is easy to remove the nut. Thus, with the help of pva-plastic, we get several finished products in one print!

One of the main disadvantages of this material is its high price and solubility in water - in some cases it is useful, and in others it is completely unacceptable. Work with PVA-plastic takes place at a temperature of 190 ° C, and its melting temperature is 160-170 ° C, the pour point (glass transition) is 45-55 ° C.

Nylon (Nylon) for 3D printing

Even more new material for 3D printing is considered to be Nylon (nylon). The material is well resistant to a wide range of solvents and chemicals. Especially popular today is Nylon from Taulman 3d.

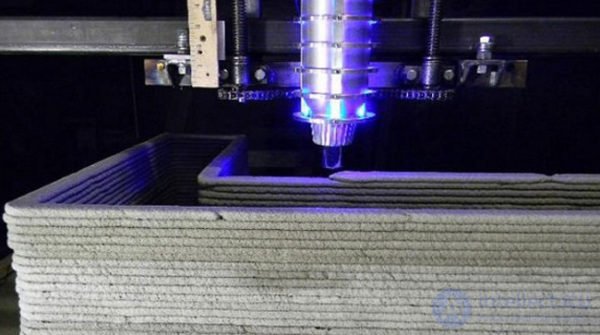

The gypsum version is also filled with powders, but already relevant - from gypsum to putty, cement and the like. Be sure to have a binder . Such printers are most often used in the creation of interior decorations. Products here are very diverse.

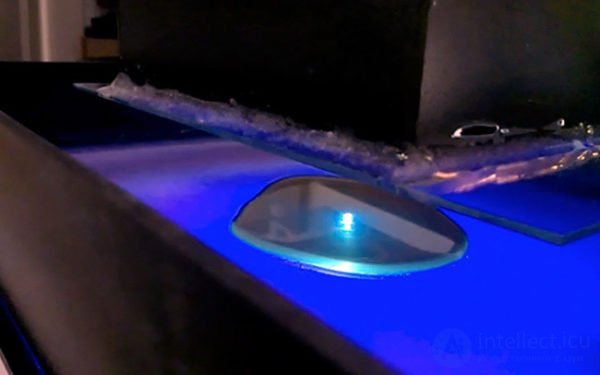

For the manufacture of objects in this case, liquid photopolymers are used. The principle of creating figures is interesting. Focusing on the computer model, the ultraviolet laser will illuminate certain places. In the future, they will harden under the action of ultraviolet radiation. Such an illumination will be carried out through a specially prepared photomask - only here will the UV lamp be used. Template preparation will change with each new layer.

If the technique is chosen stereolithographic, then you can enjoy high precision of the performance of bulk printing. The only negative is low speed, but if accuracy is a relevant indicator, then they do not pay attention to the execution time.

Such a device prints with the help of wax - a material with a low melting temperature. This property has its own bonus - the ease of operation. That is why the clarity and accuracy of the contours performed is immaculate.

To make objects of the most different colors, the technique uses a special head. Here there are several extruders - components that can melt and apply the consumables used.

Most of these units are involved in the manufacture of children's toys. Another purpose - the creation of designer jewelry.

There is another way, called " sublimation ." This type of printer is used if it is necessary to transfer an image (for example, from a photo) to a raised surface. In order to realize what was planned, dyes are heated in certain places - due to temperature effects evaporation occurs, and the desired pattern remains.

With regard to the technologies used, a special classification is applied, which will be useful for every future owner of a 3D printer to know:

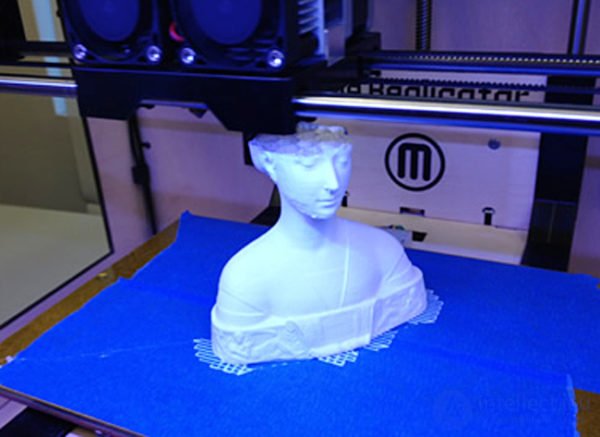

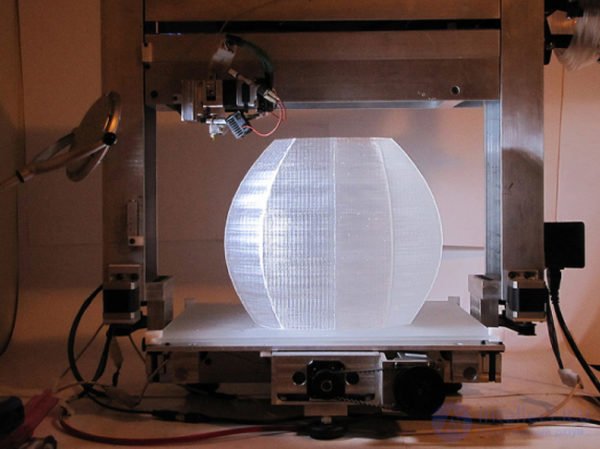

This is the most popular technology in the devices in question . With FDM (fused deposition modeling), the unit will squeeze the consumable through a special nozzle layer by layer. These include:

Interesting and MJM (Multi Jet Modeling), which involves the method of multi-jet modeling . The process is similar to a conventional inkjet due to the flow of material through small nozzles (there may be several hundred of them). After the previous layer hardens, the specified three-dimensional model will be formed.

Consumables are photoplates and plastic, suitable and special wax. Typically, such a bulk print is used in the manufacture of medical implants, dentures and casts.

Really getting multi-color options, as well as objects with different properties, for example, elastic in combination with solid.

There are also disadvantages to using such a technology - a very expensive starting material and a fragile result . Application usually finds in medicine and industrial prototyping.

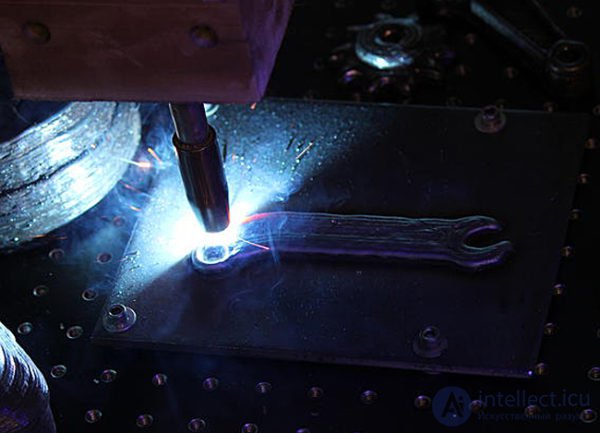

With LASER ENGINEERED NET SHAPING, the consumable consumed from the nozzle immediately falls under the focus of the laser beam, which is fraught with instant sintering. The use of metal powder helped in the manufacture of objects from steel and titanium, which made it possible to operate 3D printers in the industry. Many alloys really mix and get directly in the process. For example, get turbine titanium blades for turbines.

With Laminated Object manufacturing, thin and already laminated sheets are laser cut out, gluing, caking or pressing into a three-dimensional object. This way you can print plastic, aluminum and paper 3D objects.

By the way, the source code for aluminum objects is the corresponding foil - it will be “sinter” with the help of ultrasonic vibration.

Despite the lightness of the source material, paper models are very durable, and their cost price will be almost penny. But we must immediately prepare for the fact that such a product will be accompanied by a large amount of waste. Although the latter can be avoided by placing several small objects on one sheet at a time.

To understand how Stereolithography works, you need to imagine a bath filled with liquid polymer . A laser beam passing over its surface polymerizes the layer. After one of the layers is ready, the platform will lower the part so that the liquid polymer fills the voids. Then the situation changes: the detail rises to the top, and the laser itself is located below.

When working with this method, surface treatment is needed to sand and remove excess material. Sometimes the result is further baked in ultraviolet ovens.

Such a printer can not be kept at home:

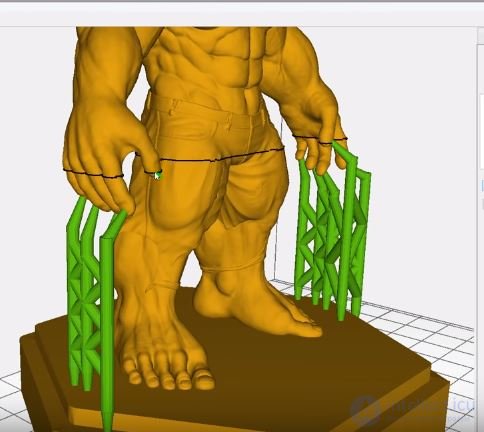

Selective laser sintering resembles the above described type of technology, but here laser powder is baked instead of photopolymer. You can not be afraid of breakage in the process of parts, and as a consumable it is likely to use steel, nylon, bronze, titanium, ceramics, glass, foundry wax and other materials.

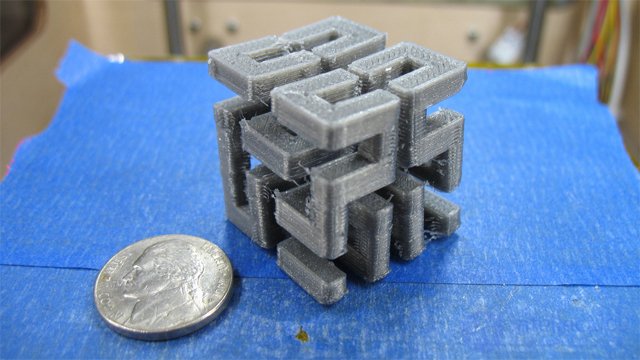

Technology involves the creation of complex things. It is great, for example, to create any prototypes - for example, for jewelry . The unbaked powder will serve as support for the overhanging elements - it means that you do not need to form any special supporting hulls.

3DP-метод заключается в нанесении на материал клея, за ним слоя свежего порошка и далее всё по новой. В результате получается похожий на гипс материал (sandstone). Если в этот клей добавить краску, то получатся цветные объекты. Технология безопасна для бытового и офисного использования. Для материалов подойдут стеклянный, костный, резиновый и даже состоящий из древесных опилок порошки. Можно делать и съедобные фигурки (с использованием шоколадного или сахарного порошков) – только в этом случае берется специальный пищевой клей.

Не обошлось и без недостатков – конечный результат может иметь грубую поверхность и невысокое разрешение.

Gcode - это текстовый файл простого формата - набор команд, по одной в каждой строке, которые понимает управляющая электроника нашего 3D принтеры. Этот же формат используется для ЧПУ.

Например, строки

M106 ; fan on G28 ; home all axes G1 Z5 F5000 ; lift nozzle

означают команды включить вентилятор на экструдере, затем переместить экструдер в начальные координаты по всем осям, а затем приподнять сопло. Далее обычно следуют команды непосредственно для печати вашего изделия.

Стремительное развитие технологий аддитивной печати было бы невозможным без современного программного обеспечения. Раньше приходилось подолгу осваивать графические редакторы и изучать азы инженерного моделирования для создания элементарных предметов.

Сегодняшний софт для 3d принтера позволяет практически полностью автоматизировать печатный процесс и значительно упростить обращение с высокотехнологичной техникой.

Практически все 3D печатающие устройства управляются так называемым G-кодом – это общепринятый язык, применяемый для аппаратов этого вида.

Таким наименованием окрестили в 60-х годах язык для станков с ЧПУ. Его начала разрабатывать американская компания Electronic Industries Alliance, затем стали применять практически все производители и пользователи автоматизированных станков.

G-код представляет собой структуру и синтаксис написания команд для обрабатывающего станка. G-код имеет международную базовую структурную основу, утверждённую американской и европейской системами стандартизации. Однако существует множество специфических дополнений и модификаций, которые локально используют производители станков и крупные корпорации, выпускающие оборудование.

Для того, чтобы получить любое изделие в 3D нужно решить две задачи:

Для построения трёхмерных объектов, как и для управления печатью, существуют специальные программы для 3D принтера.

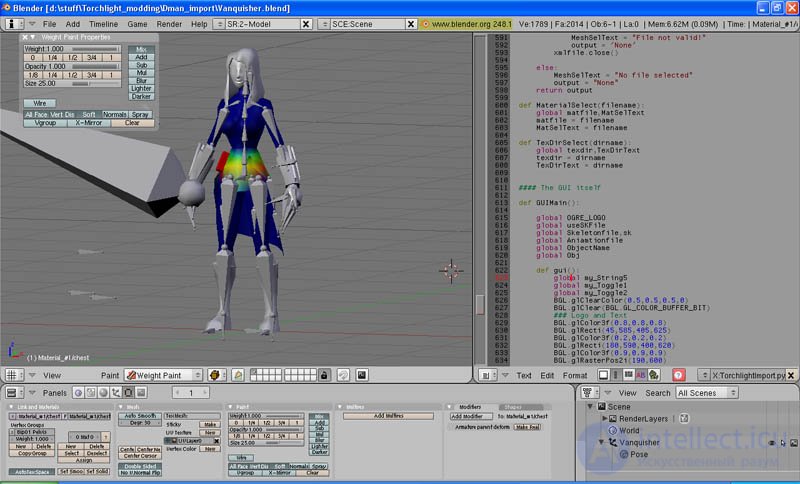

Implementing 3D printing programs work with models of three-dimensional objects. They not only have different file-building configurations, but they are not the same in content. Models of volume objects are divided into two types:

A solid object (Solid) is a vector model that describes a body entirely using mathematical vectors. In it, each point has values (coordinates, weight, color, any other properties). Since the properties and coordinates are described using vectors, such an object has infinite detailing.

Surface object (Mesh) - the model described by the "grid". Mathematical vectors described only the "thread" of the grid, surrounding the surface of the object. The network has a step between the threads that determine the accuracy of the description of the properties of the model and its parts.

Твердотельные модели содержат много информации, которая требует большое количество ресурсов. Поверхностные объекты значительно меньше по объёму, но точность отображения их свойств ограничена параметрами сетки.

Некоторые промышленные печатающие устройства, как и сложные станки с ЧПУ «умеют» работать с твердотельными массивами. Однако, все массовые бытовые и промышленные принтеры заточены только для работы только с поверхностными (сетевыми) моделями.

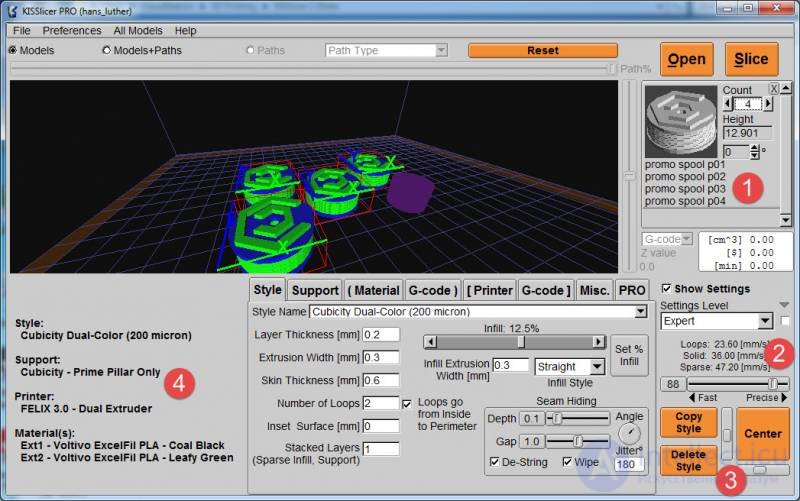

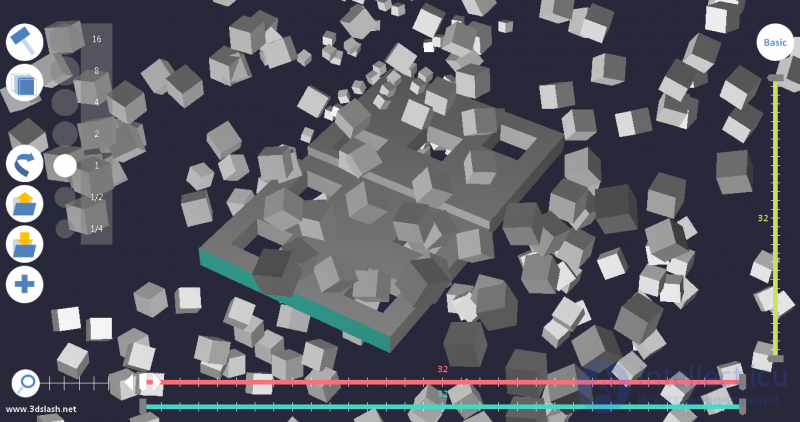

Слайсер – изначально это утилита, которая умеет из поверхностного массива сделать нарезку параллельными плоскостями и перевести полученную информацию в G-код. Ведь головки экструдера работают именно таким образом, строя объект последовательным наращиванием «срезов» поверхностей в параллельных плоскостях.

Поэтому при выходе на рынок трёхмерных принтеров появились утилиты, которые нарезают эти плоскости и, затем, управляют драйверами шаговых двигателей и соплами принтера. С развитием печатного дела в этой области, слайсеры стали оснащать и простыми инструментами построения трёхмерных объектов.

Средства, изначально предназначенные для трёхмерного моделирования намного мощнее. В них можно строить объекты любой сложности и деталировки. Но работа с ними требует определённых навыков. Тем не менее, инструменты САПР(CAD или CADD — система автоматизированного проектирования) тоже получили значительное развитие с появлением трёхмерной печати. Сегодня все мощные программы моделирования имеют встроенные возможности по компилированию своих моделей в файл формата *.stl.

Развитие печати твёрдыми материалами происходит несколькими путями. Разработчики слайсеров, другого полезного прикладного софта тоже не стоят на месте. К примеру, появились попытки представления конечного изделия со всеми возможными его изъянами и ограничениями. Это бывает очень полезно. Мощные САПР пока не могут похвастаться такими полезными возможностями, хотя в их приложениях реализованы подобные вещи для литья и механической обработки.

Кроме того, интерфейсы слайсеров сделаны интуитивно понятными и очень простыми для пользователя. Простые предметы в слайсере построить намного легче даже и опытному пользователю САПР. Значительное преимущество слайсеров, кроме простоты и доступности – фактор стоимости. Большинство из них бесплатные и свободные к распространению. Есть и платные инструменты, но их стоимость не так велика по сравнению со стоимостью САПР. Все хорошие слайсеры и оболочки имеют инструменты редактирования и построения простых объектов.

Если Вы уже используете 3D принтер, программа слайсер к нему поставлена в комплекте с первичными настройками. Однако, этого не всегда достаточно для решения Ваших задач. Программное обеспечение для 3d принтера поставляется производителем пока ещё без учёта пользовательских потребностей.

Программы, используемые для работы с 3d принтером в основном бесплатные. Только некоторые из них имеют платные версии или расширения. Все бесплатные программы, предоставляемые для 3d принтера разработчиками, пока поддерживаются и обновляются тоже на свободной основе. Многие из них имеют открытый код.

The software distributed for 3d printer, with the interface in Russian, is still quite small. But the domestic market is growing quite rapidly, and the number of adapted software is increasing. The order of the tools presented below is focused on world popularity.

The most common slicers and other useful software for a 3D printer are presented below:

One of the most popular tools for working with printing models. There are paid and free versions. Paid is distinguished by the support of several nozzles, cloud service, libraries, a large number of settings, tools.

Almost all paid options are needed for devices with several nozzles and for constructing complex objects. No great editing features. But the function of directly editing the G-code is implemented, which allows you to directly control all the organs of the device.

Free version for any operating system. On the same page you can go to the paid professional version.

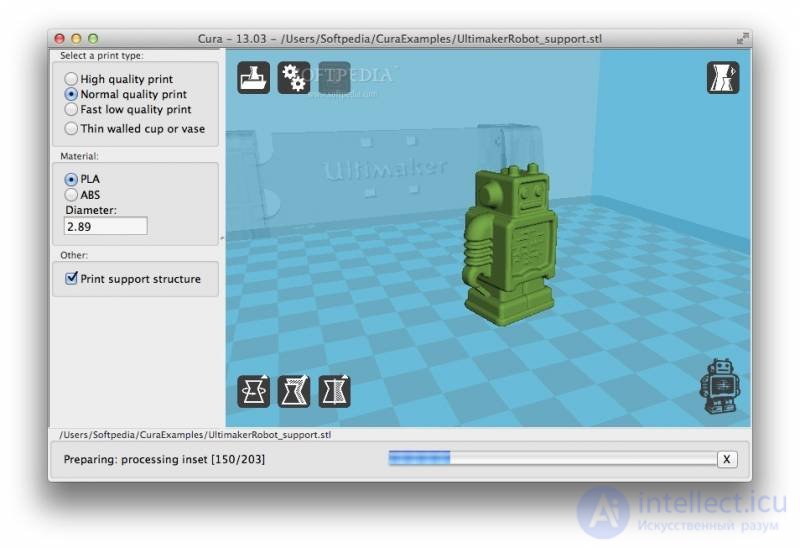

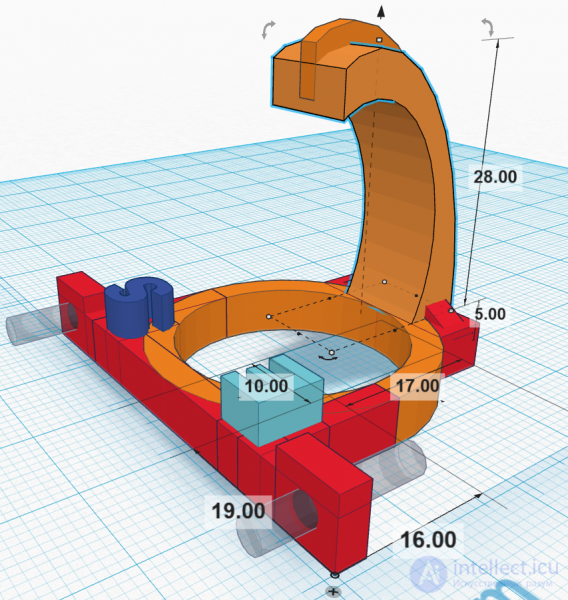

One of the most convenient and intuitive applications from the manufacturer of 3D printers Ultimaker. Received the most widespread - this is the most popular slicer for a 3D printer. In addition to editing tools, material settings, printing options, a number of convenient functions for calculating the amount of material and its cost, the weight of the product are included. It is open source. Completely free, upgradeable utility.

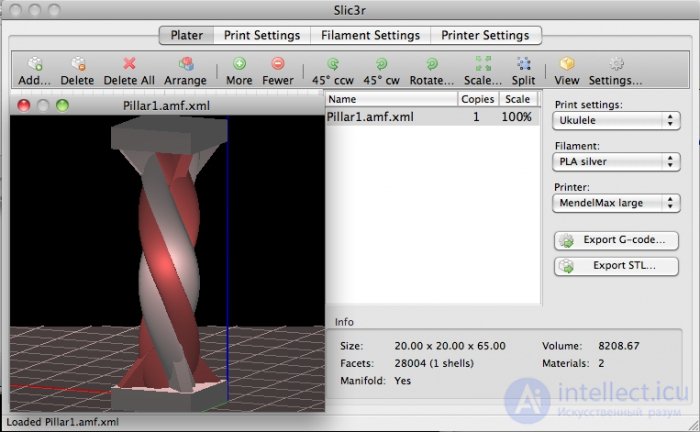

One of the most versatile and well-developed products in terms of building and editing G-code for a printer. There are settings for almost all functions of direct printing, support for several nozzles and several types of materials used. Implemented the ability to edit the G-code by the user.

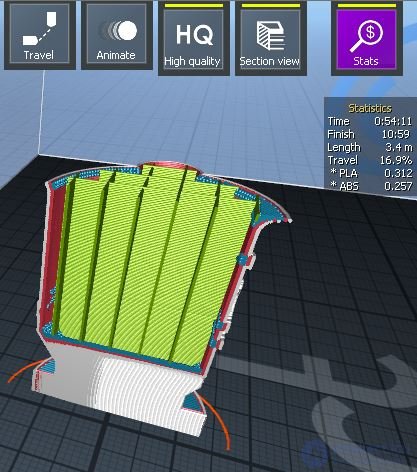

This utility is very intuitively built. However, it has several advantages. Three modes separate the preparation for the creation of a product into functions:

Print settings are implemented separately. There are functions for determining the time and preliminary cost, the function of viewing the phases of construction in time.

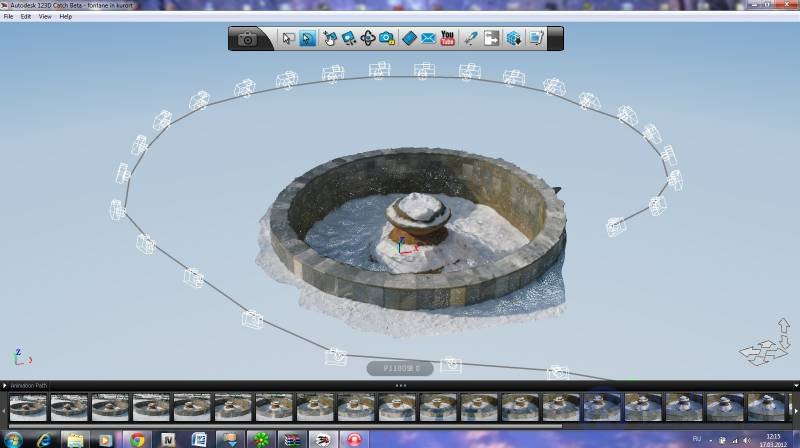

This is a tool from Autodesk that allows you to create a 3D object from camera snapshots. There is a version for Android that allows you to make a 3D scanner out of a smartphone. As a result of processing images from various angles, a surface volumetric object is constructed in several common 3D graphics formats.

All operations are performed in the cloud service using email to receive the final file. Product visualization takes place directly in the utility environment. Distributed and maintained for free.

Very powerful cloud program that allows you to create, edit and print 3D objects. Intuitive, interactive interface is well perceived to use all functions. In addition to loading, creating, editing objects, all the slicer and print control functions are implemented. Perhaps the most simple and versatile 3d printer software that allows you to create and print various items.

Fully cloud service from Autodesk, which allows you to work with 3D models, create them, edit, send to print. There is a very large number of services and features, functions of construction and print management. This is not the most functional printer management utility, since it was originally developed for other application machines, but these functions are constantly being developed by the developer, and the coverage of various standards is increasing.

Getting started with the service in Russian is possible after registration https://www.tinkercad.com/. There is also a small training course.

Online editor for building and editing network 3D models. Very simple, fast and intuitive. Does not require initial skills. It works only in the cloud. Allows you to create simple objects and then convert them to stl - files.

The service is one of freely distributed CAD tools, work with which is possible only after registering at https://www.tinkercad.com/ or Autedesk tool server http://formit360.autodesk.com/.

An interesting three-dimensional editor. Very simple, but quite functional for building various products from a large library of primitives. For editing there is a set of handy tools. Saves files in most used formats, so it is often used as a converter. Initially, the utility was written for volumetric animation, but constant improvements and extensions made it quite suitable for designing parts. The tool is distributed for free, has an open code.

3D printing attracts a large number of people interested in it because of personal curiosity or for production purposes. For those who have no experience in this field, it will not be difficult to learn the art of bulk printing, both on virtual and real courses. It will be more important: for what specific purposes it is planned to buy such a device. The correct prioritization, combined with the knowledge of the technology used for a particular application, will make it possible to use the technology to the full.

The list of presented tools for three-dimensional printing is not at all complete - there are already many more. New ones appear, and the existing ones are improving very quickly. Intuitive G-code editing options, simple ways to edit surface objects, and visual control tools for direct printing functions appear. We are on the verge of a technological take-off of this new industry, making our feasible user contribution to its development and improvement.

Comments

To leave a comment

Electromechanical devices of electronic devices

Terms: Electromechanical devices of electronic devices