Lecture

A nickel cadmium accumulator (NiCd) is a secondary chemical current source, in which the cathode is nickel hydroxide Ni (OH) 2 with graphite powder (about 5-8%), and potassium hydroxide KOH with a density of 1.19-1.21 s the addition of lithium hydroxide LiOH (for the formation of lithium nickelates and an increase in capacity by 21-25%), the anode - cadmium oxide hydrate Cd (OH) 2 or metallic cadmium Cd (in the form of powder). The emf of a nickel-cadmium battery is about 1.37 V, the specific energy is about 45–65 Wh / kg. Depending on the design, mode of operation (long or short discharges) and the purity of the materials used, the service life ranges from 100 to 9000 charge-discharge cycles. Modern (lamellar) industrial nickel-cadmium batteries can last up to 20-25 years. Nickel-cadmium batteries (Ni-Cd) along with Nickel-Salt batteries can be stored discharged, unlike nickel-metal hydride batteries (Ni-MH), which need to be stored fully charged and from lithium-ion batteries (Li-ion) , which must be stored at 40% charge from the battery capacity. Silver-zinc batteries are stored only discharged.

The principle of operation of nickel-cadmium batteries is based on a reversible process:

2NiOOH + Cd + 2H 2 O 2Ni (OH) 2 + Cd (OH) 2 E 0 = 1.30 V.

The nickel electrode is a nickel hydroxide paste mixed with a conductive material and deposited on a steel mesh, and the cadmium electrode is a steel mesh with a spongy cadmium pressed into it. The space between the electrodes is filled with a gelatinous composition based on wet alkali, which freezes at -27 ° С [1] . Individual cells are collected in batteries with a specific energy of 20–35 Wh / kg and having a large resource — several thousand charge-discharge cycles.

Currently, the use of nickel-cadmium batteries is severely limited for environmental reasons, so they are used only where the use of other systems is impossible, namely, in devices characterized by large discharge and charging currents. A typical battery for a flying model can be charged in half an hour, and discharged in 5 minutes. Due to the very low internal resistance, the battery does not heat up even when charged with a large current. Only when the battery is fully charged does a noticeable warm-up begin, which is used by most chargers as a signal to stop charging. Structurally, all nickel-cadmium batteries are equipped with a durable hermetic casing that withstands the internal pressure of gases in severe operating conditions.

The discharge cycle starts at 1.35 V and ends at 1.0 V (respectively 100% capacity and 1% of the remaining capacity)

Electrodes of nickel-cadmium batteries are made by stamping a sheet or by pressing out of powder. Pressed electrodes are more adaptable, cheaper to manufacture and have higher working capacity, and therefore all household batteries have pressed electrodes. However, extruded systems are subject to the so-called "memory effect". The memory effect occurs when the battery is charged before it is actually discharged. In the battery's electrochemical system, an “extra” electrical double layer appears and its voltage drops by 0.1 V. A typical device controller using a battery interprets this voltage reduction as a complete discharge of the battery and reports that the battery is “bad.” There is no real reduction in energy consumption, and a good controller can ensure full use of battery capacity. However, in a typical case, the controller prompts the user to perform more and more new charge cycles. And this leads to the fact that the user, with the best of intentions, "kills" the battery. That is, it can be said that the battery fails not so much from the “memory effect” of pressed electrodes, but from the “effect of unconsciousness” of inexpensive controllers.

A household nickel-cadmium battery, discharged and charged with weak currents (for example, in the TV remote control), quickly loses its capacity and the user finds it out of order. Similarly, a battery that has been recharging for a long time (for example, in an uninterruptible power system) will lose capacity, although its voltage will be correct. That is, the use of a nickel-cadmium battery in the buffer mode is impossible. Nevertheless, one cycle of deep discharge and subsequent charging will fully restore the battery capacity.

When storing NiCd batteries also lose their capacity, although they retain the output voltage. To avoid incorrect sorting when removing batteries from storage, it is recommended to store them in a discharged form, then after the first charge the batteries will be fully ready for use. It is best to connect a chain of two diodes and a resistor to each bank in order to limit the voltage at a level of 1-1.1 V per element. It also helps align the characteristics of the cells that make up the battery. After long-term storage of the battery, it is necessary to carry out 2–3 charge / discharge cycles with a current that is numerically equal to the nominal capacity (1C) in order for it to enter operating mode and work at full efficiency.

Small-sized nickel-cadmium batteries are used in various devices as a replacement for a standard galvanic cell, especially if the equipment consumes a large amount of current. Since the internal resistance of a nickel-cadmium battery is one to two orders of magnitude lower than that of conventional zinc-manganese and manganese-air batteries, power is delivered more stable and without overheating.

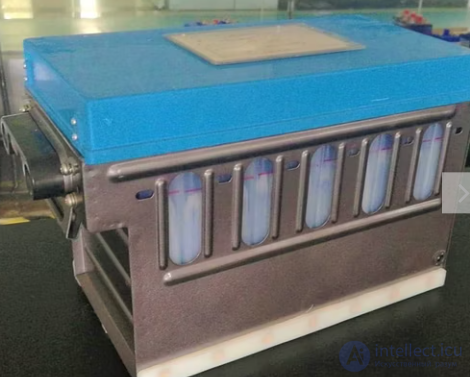

Nickel-cadmium batteries are used on electric cars (as traction vehicles), trams and trolley buses (for powering control circuits), river and sea vessels. They are widely used in aviation as onboard batteries of airplanes and helicopters. Used as power supplies for stand-alone screwdrivers / screwdrivers and drills.

Despite the development of other electrochemical systems and the tightening of environmental requirements, nickel-cadmium batteries remain the primary choice for highly reliable devices that consume more power, such as diving lamps.

In the USSR, for the power supply of electronic devices, sealed (explode) nickel-cadmium accumulator batteries were distributed.

| Title battery |

diameter mm |

height mm |

voltage volt |

Capacity A * h |

Recommended discharge current, mA | Application |

|---|---|---|---|---|---|---|

| D-0.03 | 11.6 | 5.5 | 1.2 | 0.03 | 3 | cameras, Hearing Aids |

| D-0.06 | 15.6 | 6.4 | 1.2 | 0.06 | 12 | cameras, photo exposure meters, hearing aids, dosimeters |

| D-0.125 | 20 | 6,6 | 1.2 | 0.125 | 12.5 | rechargeable electric flashlights |

| D-0,26 | 25.2 | 9.3 | 1.2 | 0.26 | 26 | rechargeable electric flashlights, flashlights, calculators |

| D-0,55 | 34.6 | 9.8 | 1.2 | 0.55 | 55 | flashlights |

| 7D-0.125 | 8.4 | 0.125 | 12.5 | replacement battery Krone |

Ni-Cd batteries produce many companies, including large international companies, such as GP Batteries Int. Ltd., SAMSUNG (under the brand Pleomax), VARTA, GAZ, KONNOC, METABO, EMM, Advanced Battery Factory, Panasonic / Matsushita Electric Industrial, ANSMANN and others. Among domestic manufacturers are NIAI (established on the basis of the Central Battery Laboratory, 1946), KOSMOS, ZAO Experimental Plant NIIHIT and ZAO NIIHIT-2.

Melting of NiCd battery recycling products occurs in furnaces at high temperatures, cadmium under these conditions becomes extremely volatile, and if the furnace is not equipped with a special catching filter, toxic substances (for example, cadmium vapor) are released into the external environment, poisoning the surrounding areas. As a result, disposal equipment is more expensive than lead batteries.

Comments

To leave a comment

Power supplies for electronic equipment

Terms: Power supplies for electronic equipment