Lecture

1.1.1 Types of measurements

Types of measurements are determined by the physical nature of the measured quantity, the required accuracy and the required measurement speed, measurement conditions, etc. You can select the types of measurements depending on their purpose: control, diagnostic, laboratory, technical, reference, calibration, absolute, relative, etc.

According to general methods of obtaining measurement results, they are divided into: direct, indirect, joint and cumulative.

Direct - measurements in which the value of a physical quantity is found directly from the experimental data. Direct measurements are characterized by the formula:

A = x, (1.1)

where x is the value of a value found by measuring it and

called the measurement result.

An indirect term is a measurement in which the sought-after value of a quantity is found on the basis of a known relationship between this quantity and the quantities subjected to direct measurements. Indirect measurements can be characterized by the following formula:

A = f (x1, x2, ..., xm), (1.2)

where x1, x2, ..., xm are the results of direct measurements of quantities related to the functional dependence of f with the desired value of the measured quantity A.

Indirect measurements include the determination of the resonant frequency of an oscillating circuit from the results of direct measurements of capacitance and inductance, etc.

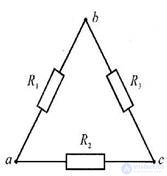

Aggregate is the simultaneous measurement of several values of the same name, at which their values are found by solving a system of equations obtained by direct or indirect measurements of various combinations of these values. In this case several combinations of values of quantities can be measured. For example, by measuring the resistances Rab, Rac and Rbc between the vertices of a triangle of an electrical circuit in which the resistances of resistors R1, R2 and R3 are connected (Fig. 1.1) and by solving a system of equations like (1.5), we can determine the desired values of resistances R1, R2 and R3 cumulative measurements:

Figure 1.1 To the cumulative measurement method

R ab = R R 1 (+ R R 2 ++ R R 3); R ac = R R 2+ ( R R 12 ++ R R 3); R bc = RR 13+ ( RR 12 ++ RR 2) 3, (1.3)

R ab = R R 1 (+ R R 2 ++ R R 3); R ac = R R 2+ ( R R 12 ++ R R 3); R bc = RR 13+ ( RR 12 ++ RR 2) 3, (1.3)

1 2 3 1 3

Joint called simultaneous measurements of two or more of the same quantity to establish the relationship between them.

As can be seen from the definitions, the cumulative and joint measurements are very close to each other. In both cases, the desired values are found as a result of solving a system of equations, the coefficients of which are obtained by direct measurements. The difference is that in the case of cumulative measurements, several values of the same name are determined at the same time, and in joint measurements they are determined by opposite values.

The most well-known example of joint measurements is to determine the dependence of the resistor's resistance on temperature:

R1 = R 20 [1+ α (t - 20) + β (t - 20) 2], (1.4)

where R20 is the resistance of the resistor at t = 20 ° С; α, β - temperature

coefficients.

To determine R20, α and β, first measure the resistance Rt of a resistor at, for example, three different values of temperature (t1, t2, t3), and then make up a system of three equations, by which parameters are found

R20, α and β.

R t 1 = R 20 [1 + α ( t 1 −20) + β ( t 1 −20) 2];

R t 2 = R 20 [1 + α ( t 2 −20) + β ( t 2 −20) 2];

R t 3 = R 20 [1 + α ( t 3 - 20) + β ( t 3 - 20) 2].

Indirect, joint and cumulative measurements are combined by a common property: their results are calculated from the known functional dependencies between the measured values and the values determined by direct measurements. The difference between these types of measurements is only in the form of the functional dependence used in the calculations. In indirect measurements, it is expressed by one equation in an explicit form, with joint and aggregate - by a system of implicit equations.

Depending on the expression of the measurement results are divided into:

absolute and relative.

Absolute measurements are based on direct measurements of one or more quantities using the values of physical constants. The result of the absolute measurement is directly expressed in units of the measured value.

Relative measurements are measurements of the ratio of a value to a value of the same name, which plays the role of a unit, or a change in a value with respect to a value of the same name taken as the original.

In relative measurements, a non-systemic dimensionless unit — decibels (dB) is used, which is determined when comparing the voltages (sometimes currents) of U2 and U1:

1 dB = 20 lg (U2 / U1), with U2 / U1 = 1О1 / 20 = 1,122;

and when comparing the powers of P2 and P1;

1 dB = 101g (Р2 / Р1), with Р2 / Р1 = 101/10 = 1.259.

Reference tables are used to convert the power and voltage ratios (currents) to decibels and back.

1.1.2 Measurement methods

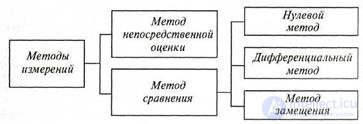

Specific measurement methods are determined by the type of measured values, their size, the required accuracy of the result, the speed of the measurement process, the conditions under which measurements are taken, and a number of other signs. Modern measurement methods can be divided into the method of direct evaluation and the method of comparison (Fig. 1.2).

Figure 1.2 Classification of measurement methods

In the method of direct assessment, the numerical value of the measured physical quantity is determined directly from the meter reading (for example, voltage measurement with a voltmeter, current strength with an ammeter). The speed of the measurement process by direct evaluation makes it often indispensable in practice, although the measurement accuracy is usually limited.

Comparison method - a measurement method in which the measured value is compared with the value reproduced by the measure. This may be, for example, a measurement of DC voltage by comparing with the EMF of the reference element. Devices that implement measurement by the method of comparison, called measuring devices comparison. Unlike devices of direct assessment, convenient for obtaining operational information, comparison devices provide greater accuracy of measurements.

There are the following types of comparison method;

• zero method , in which the action of the measured value is fully balanced model;

• the differential method , when the difference between the measured value and the one close to it by the value of a known reference is measured (for example, measurement of electrical resistance by the method of an unbalanced bridge); This comparison method is used when the deviation of the measured value from a certain nominal value (frequency drift, voltage deviation, etc.) is of practical importance;

• the substitution method , in which the action of the measurand is replaced by the exemplary one.

The zero method provides the greatest accuracy of measurements of a physical quantity. Its varieties are:

• compensation method in which the action of the measured value is compensated (balanced) exemplary;

• the bridge method , when it reaches zero current in the measuring diagonal of the bridge, which includes a sensitive indicator device (usually a null indicator).

According to the method of conversion of the measured value and the form of presentation of the result of the measurement are divided into: analog and digital.

In analog measurements, the measuring device continuously converts the measured value, the result of which is the movement of the pointer relative to the scale. The operator makes a conclusion on the numerical value of the value, noting the position of the pointer relative to the instrument scale marks.

In the case of digital measurements, the comparison of a physical quantity with a number of exemplary values is performed automatically in the instrument, while the operator receives the numerical value of the measured quantity in digital form.

By the nature of the change in the measured physical quantity over time, the static and dynamic measurement modes are distinguished.

Static measurement mode - a mode in which the measuring instrument operates in a static mode, while the output signal remains unchanged during the time of its study or changes very slowly.

The dynamic measurement mode is the mode that results in the functional dependence of the measured value on time, i.e. when the output signal changes in time according to the change in time of the measured value. So, dynamic measurements are used to measure the parameters of quantities that are time dependent. An example of a dynamic measurement is the determination of the instantaneous values of signals over a period of time.

Depending on the method of measurement and the properties of the measuring instruments used, all types of measurements can be performed either with single or multiple observations.

1.1.3 Measuring instruments and their classification

A measuring instrument (SI) is a technical tool (or their complex) intended for measurements, having normalized metrological characteristics, reproducing and (or) storing a unit of physical quantity, the size of which is assumed to be constant during a known time interval.

Measured with acceptable accuracy is possible provided that the measuring instrument provides storage (or reproduction) of the unit of the measured value almost unchanged both in time and under the influence of environmental factors. Moreover, this immutability of the size of a unit over time and its susceptibility to change under the influence of influencing factors must be controlled. Depending on the quality requirements of the measurements, this control is carried out using various measuring instruments.

For measuring instruments, it is possible to single out some common characteristics inherent in all measuring instruments, regardless of the application.

According to the role played in the system for ensuring the uniformity of measurements , the following measuring instruments are distinguished:

• metrology designed for metrology purposes - reproducing a unit and (or) storing it or transferring the size of a unit to working measuring instruments;

• workers employed for measurements not related to the transfer of unit sizes.

Metrological measurement tools are very few. They are developed, produced and operated in specialized research centers. Therefore, the vast majority of measuring instruments used in practice belong to the second group.

According to the level of automation, all measuring instruments are divided into:

• manual ;

• automated , automatically producing one or part of a measuring operation;

• automatic , performing in the automatic measurement mode all operations related to the processing of their results, registration, data transmission or generation of control signals.

In relation to the measured physical quantity , the following measuring instruments are distinguished:

• Basic - measuring instruments of the physical quantity, the value of which must be obtained in accordance with the measurement task;

• auxiliary - measuring instruments of the physical quantity, the effect of which on the main measuring instrument or object of measurement must be taken into account in order to obtain measurement results of the required accuracy.

By implementing a measurement procedure, measurement tools are elementary and complex.

Measuring instruments are divided into measures, comparison devices (comparators), measuring transducers, measuring instruments, measuring installations and measuring systems.

1.1.4 Elementary Measuring Instruments

Elementary measurement tools are designed to implement individual direct measurement operations. These include measures, comparison devices and measuring transducers. Each of them, taken separately, cannot perform a measurement operation.

Measure - a measurement tool that reproduces the physical quantity of a given size (value). As a measure in radio measurements using a measuring resistor (a measure of electrical resistance), etc. Measures are unambiguous and multivalued:

• The unambiguous measure reproduces the physical quantity of the same size;

• A multi-valued measure reproduces a series of like quantities of various sizes, for example, a potentiometer, a variable capacitor.

In addition, there are distinguished sets of measures, shops of measures, installation and built-in measures. A set of measures is a specially selected set of similar elements used not only separately, but also in various combinations to reproduce a number of similarly sized values of different sizes, for example, a set of measuring resistors or capacitors.

A comparator (comparator) is a measurement tool that allows you to compare with one another the measures of homogeneous quantities or the readings of measuring instruments. An example would be a photo relay that switches on (off) street electric lighting.

A measuring transducer is a measuring instrument that generates a signal of measurement information in a form convenient for transmission, transformation, processing and storage, but not amenable to direct perception of the researcher.

By type of input and output values, the measuring transducers are divided into:

• analog , converting one analog value to another analog value;

• analog-digital (ADC), designed to convert an analog measurement signal into a digital code;

• digital-analog (D / A), designed to convert a digital code into an analog value.

1.1.5 Integrated Measuring Instruments

Comprehensive measurement tools designed to implement the entire measurement procedure. These include: measuring devices, measuring installations and measuring systems.

A measuring device is a measuring instrument designed to generate a specific type of measurement information signal in a form that is accessible for direct perception by the operator.

In radio engineering, the measuring information signal is an electrical signal, functionally related to the physical quantity being measured. The informative parameter of the input electrical signal of the measuring instrument is the parameter of the input signal, functionally related to the physical quantity being measured and used to transmit its value or is the measured quantity itself.

Measuring facility - a set of functionally combined measuring instruments and auxiliary devices designed to generate signals of measuring information in a form convenient for the observer to directly perceive.

Measuring system (IC) is a set of measuring instruments and auxiliary devices interconnected by communication channels, designed to generate measurement information signals in a convenient form for automatic processing, its transmission and use in control systems. Measuring systems are conventionally divided into information-measuring systems (IMS), measuring

computer complexes (ICS) and computer - measuring systems (CIS).

Information-measuring systems - a set of functionally combined measuring instruments , computer equipment and auxiliary devices connected to each other by communication channels designed to generate measurement information signals on physical quantities characteristic of this transmission and (or) use in automatic control systems.

Measuring and computing complexes are a combination of measuring instruments and computers, combined with the help of interface devices and intended for measurement, scientific research and calculations.

A computer-measuring system (virtual device) consists of a standard or specialized computer with a data acquisition board (module) built into it.

1. What is the discipline of metrology?

2. What is the place of metrology among other sciences?

3. Give the definition of a physical quantity.

4. What is the dimension of a physical quantity?

5. Give examples of basic, additional and derived physical quantities.

6. What are the characteristics classified measurement methods?

7. What measurement methods do you know?

8. What are measurement conditions? What are they like?

9. What is the measurement result and how is it characterized?

10. Give the definition of direct, indirect, joint and cumulative types of measurements.

11. Give examples of measurements of each type.

Comments

To leave a comment

METROLOGY AND ELECTROradio-measurement

Terms: METROLOGY AND ELECTROradio-measurement